Measurement of rotational speed by rotating shaft

(with Handheld Digital Tachometer)

A-1-1

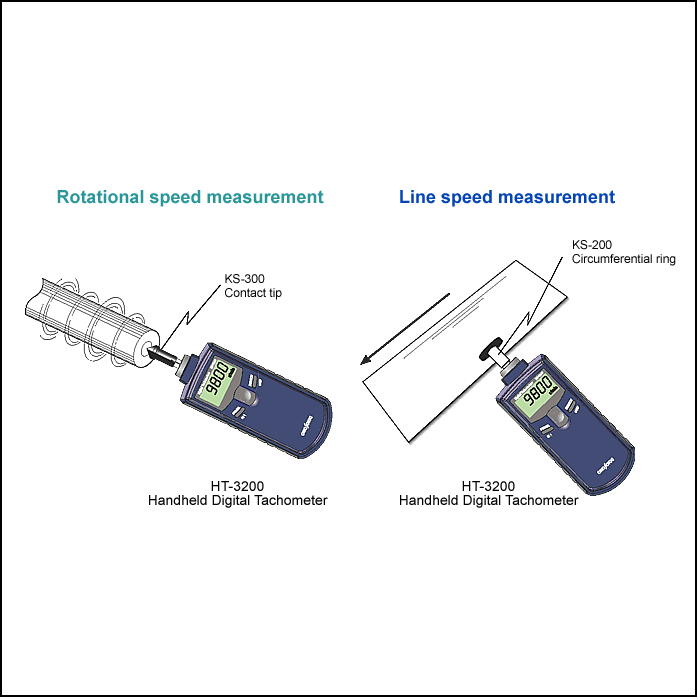

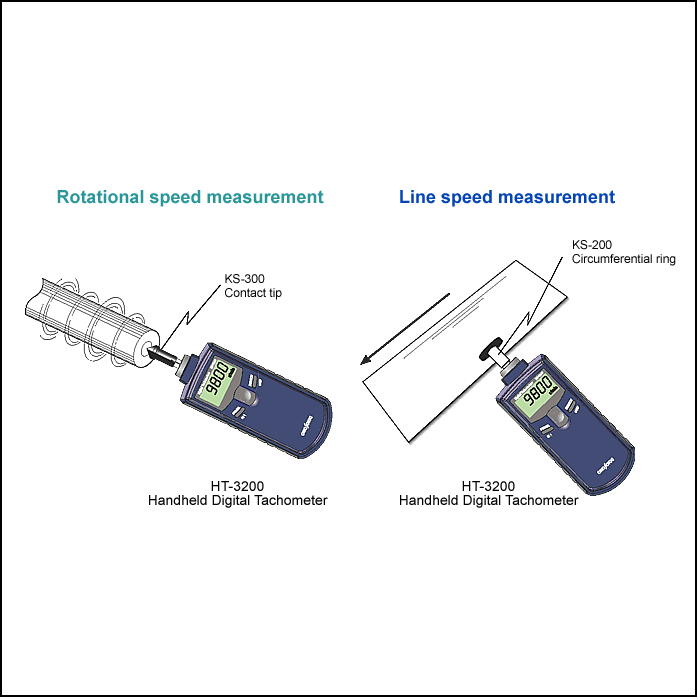

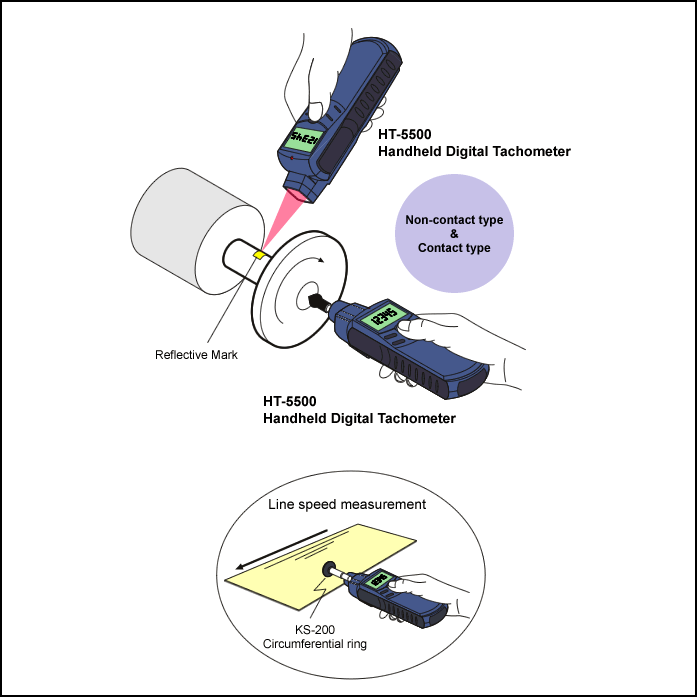

Rotational and line speed measurement with Contact type Handheld Digital Tachometer

A-1-2

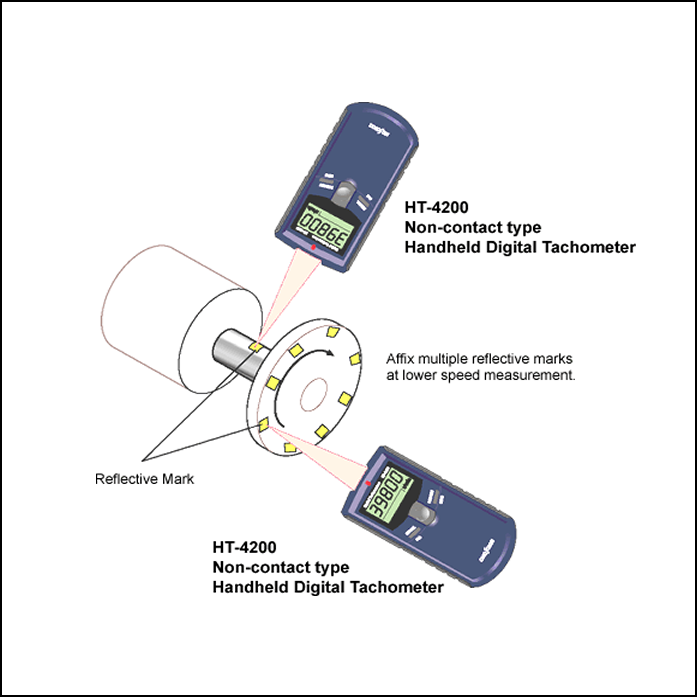

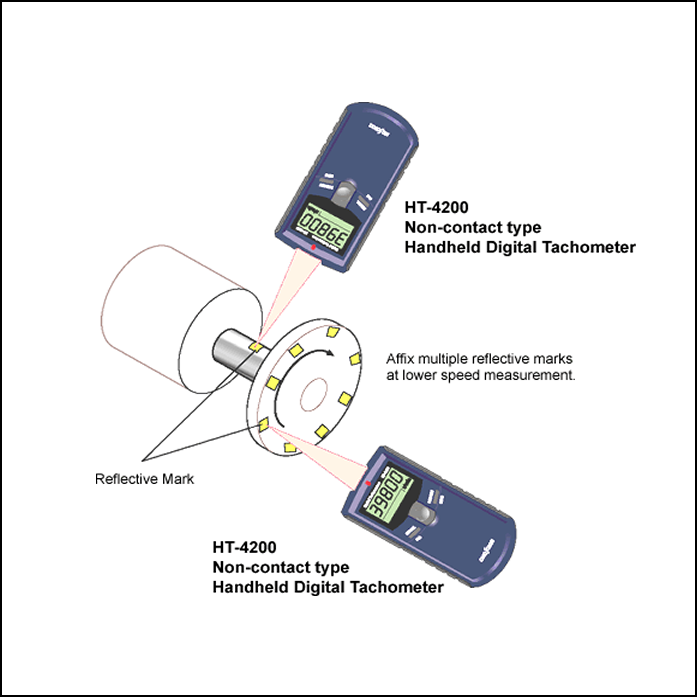

Rotational speed measurement with Non-contact type Handheld Digital Tachometer

A-1-3

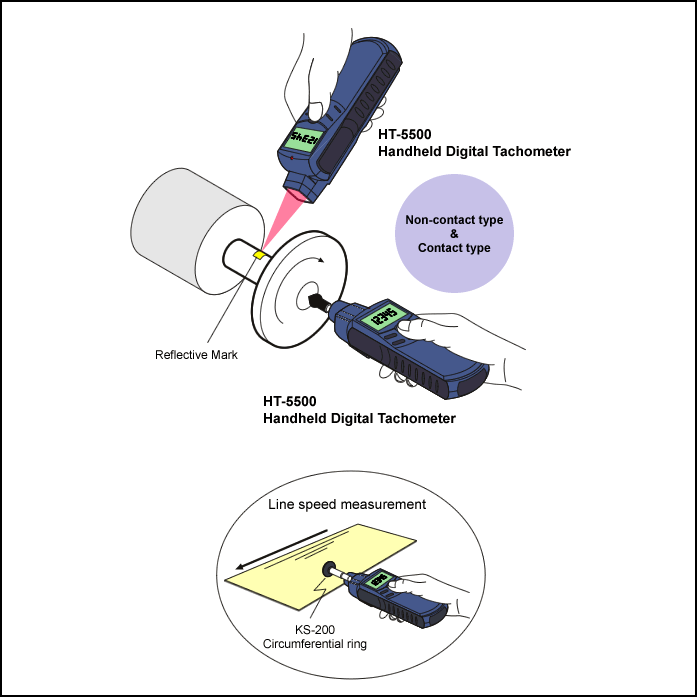

Rotational speed measurement with Contact/Non-contact type Handheld Digital Tachometer

A-1-4

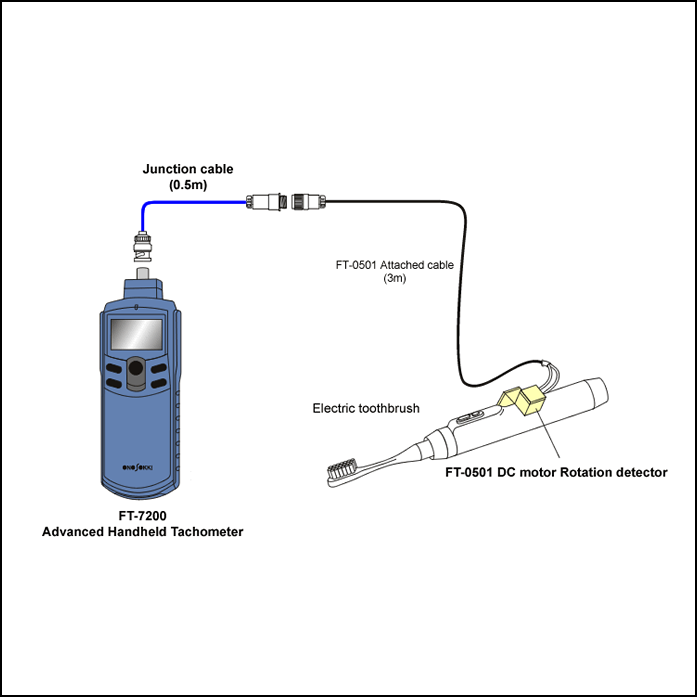

Measuring the rotational speed of the motor by its magnetic flux leakage (FFT calculations)

A-1-5

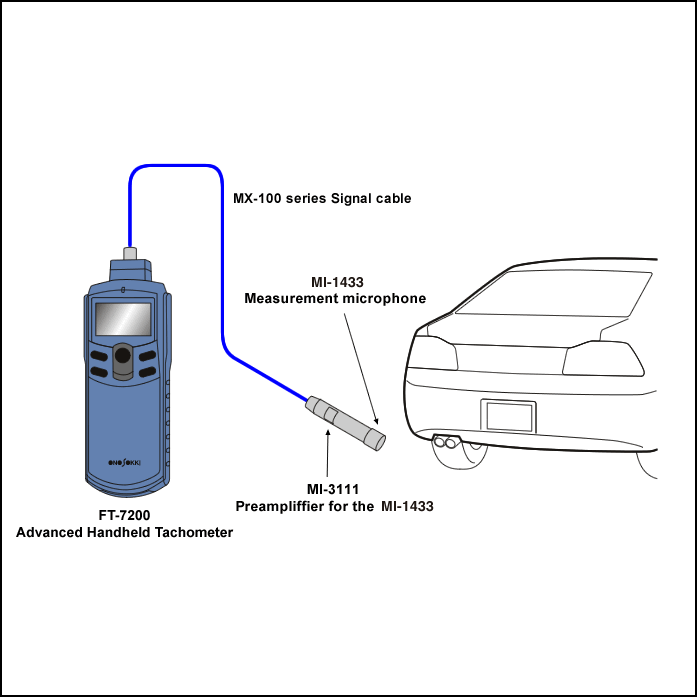

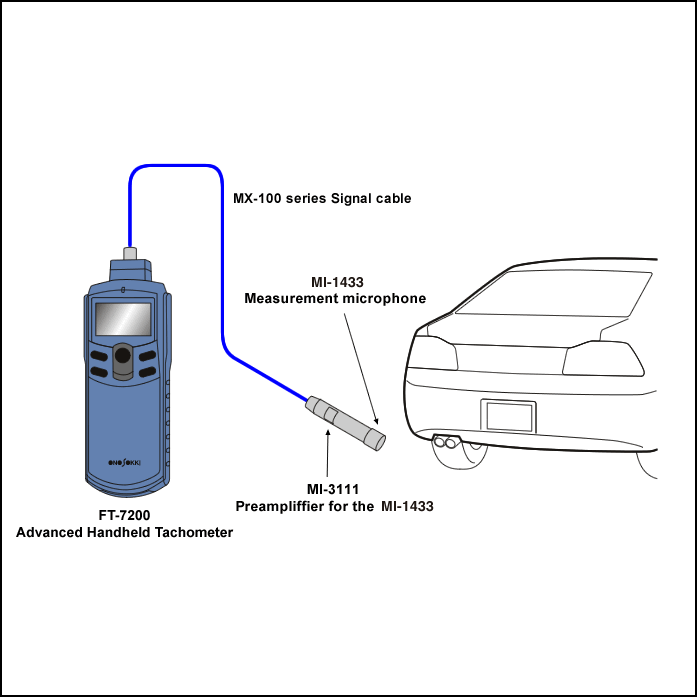

Using a microphone to measure the rotational speed of an engine from the muffler noise

(FFT calculation)

A-1-6

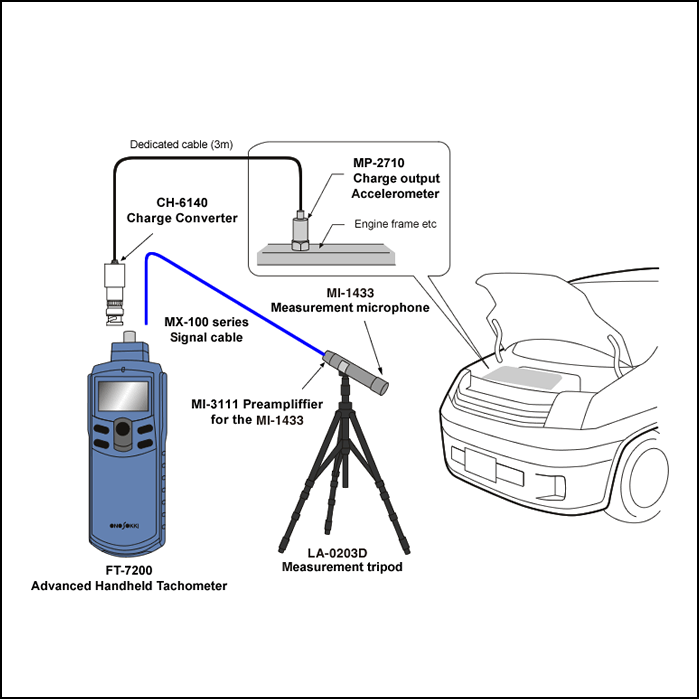

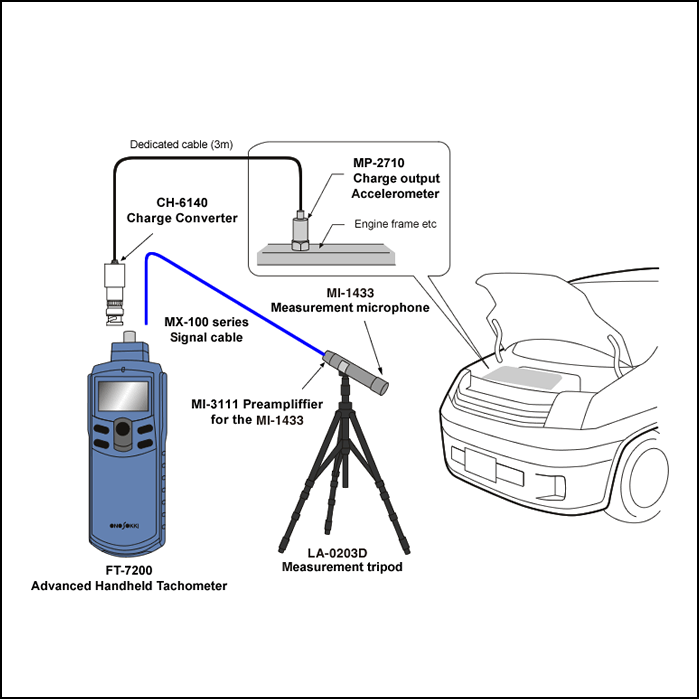

Using a microphone or accelerometer to measure the rotational speed of an engine

(FFT calculation)

A-1-7

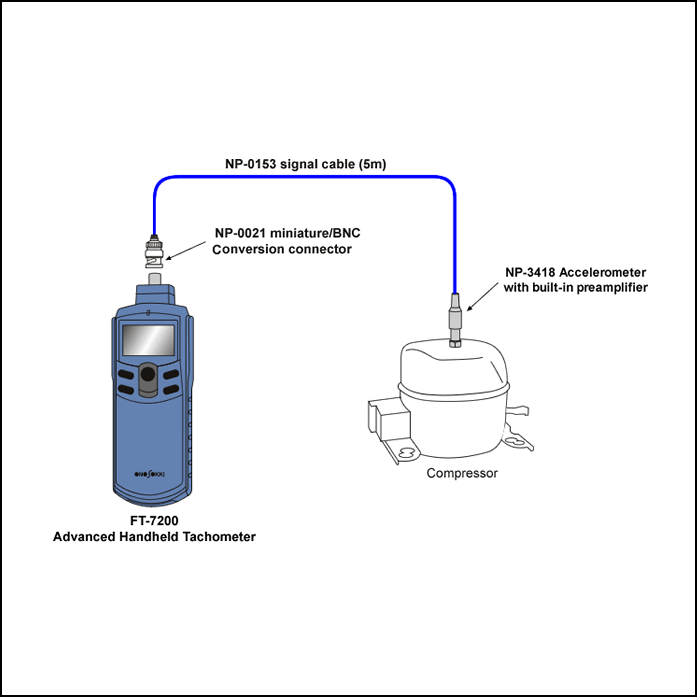

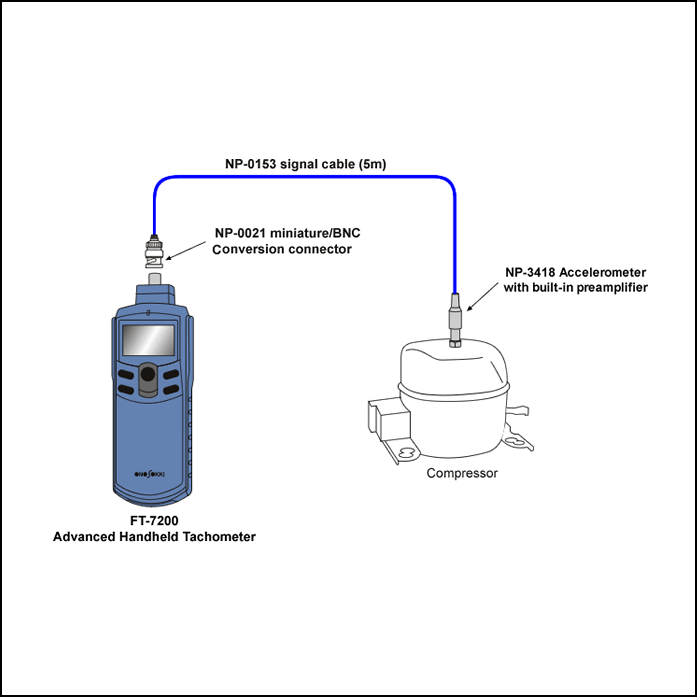

Using a accelerometer to measure the rotational speed of a compressor (FFT calculation)

A-1-8

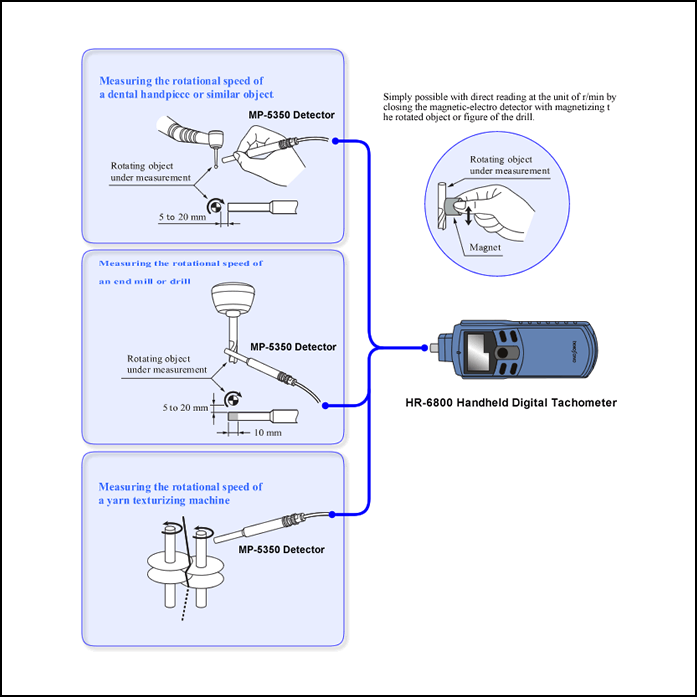

Measuring the high-speed rotation (maximum to 999,990 r/min) with Non-contact method

A-1-9

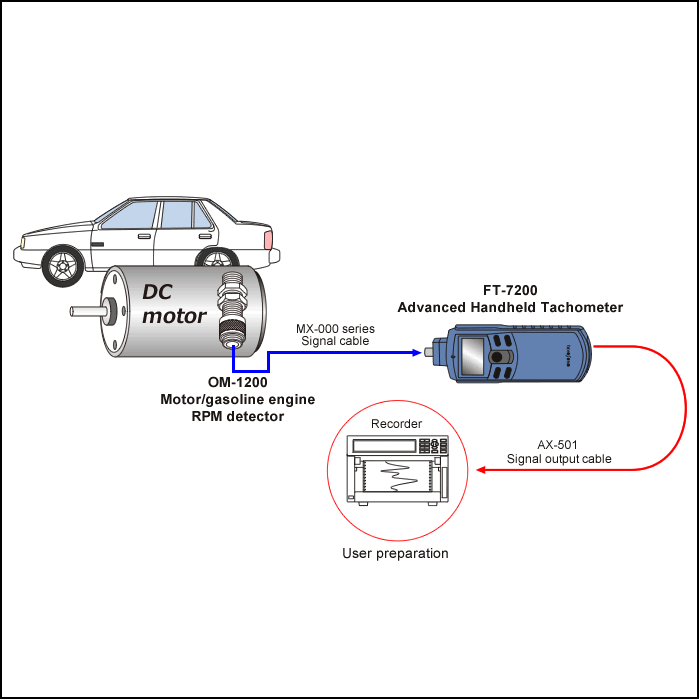

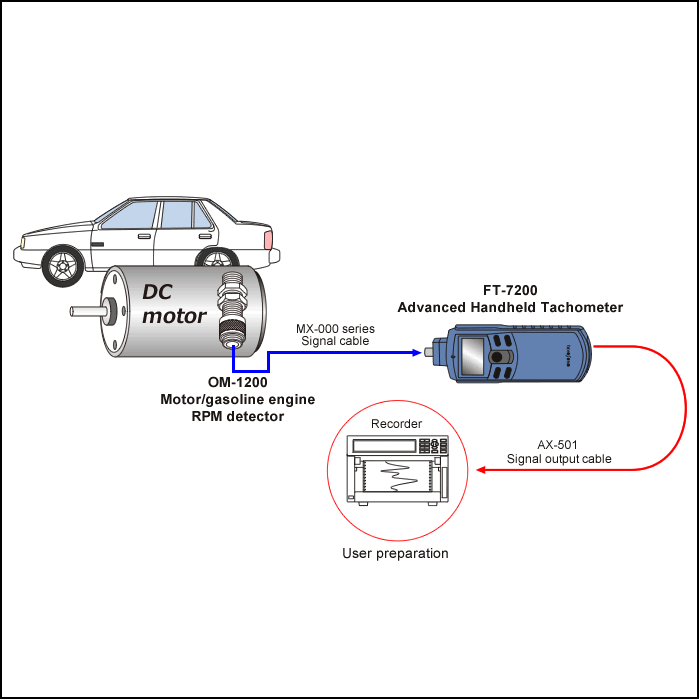

Measuring rotation speed of a DC motor in an EV (FFT calculation)

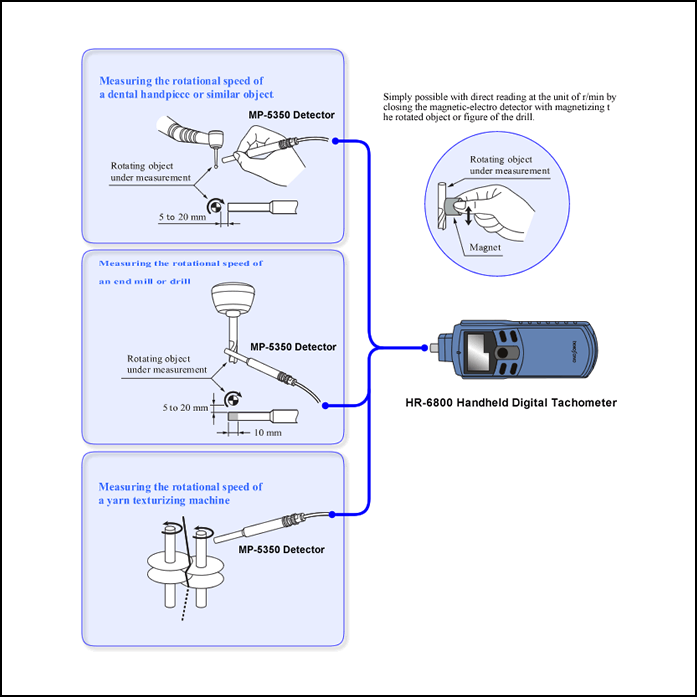

Measurement with Non-contact type detector

A-2-1

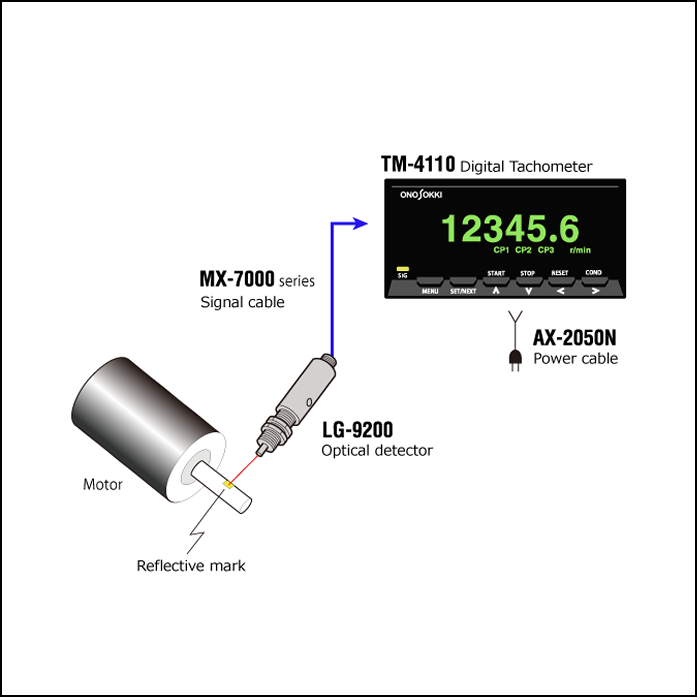

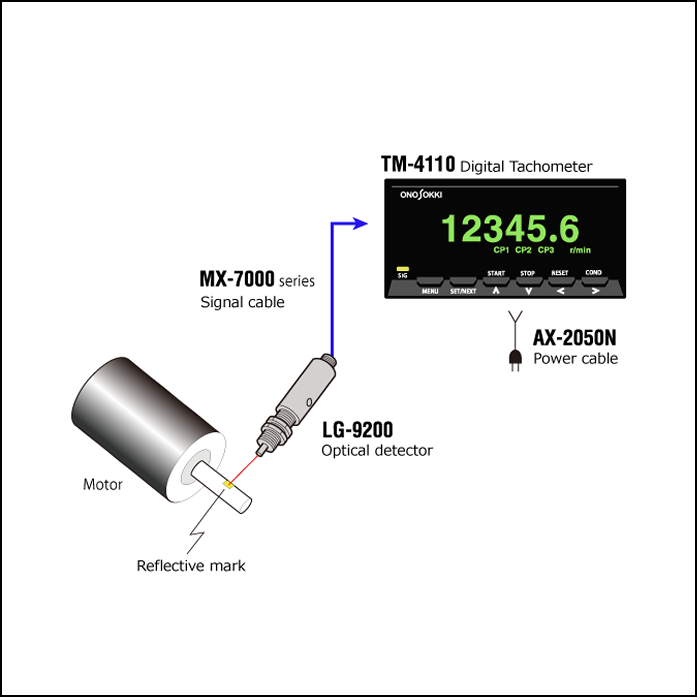

Measuring the rotational speed with Non-contact type optical detector-1

A-2-2

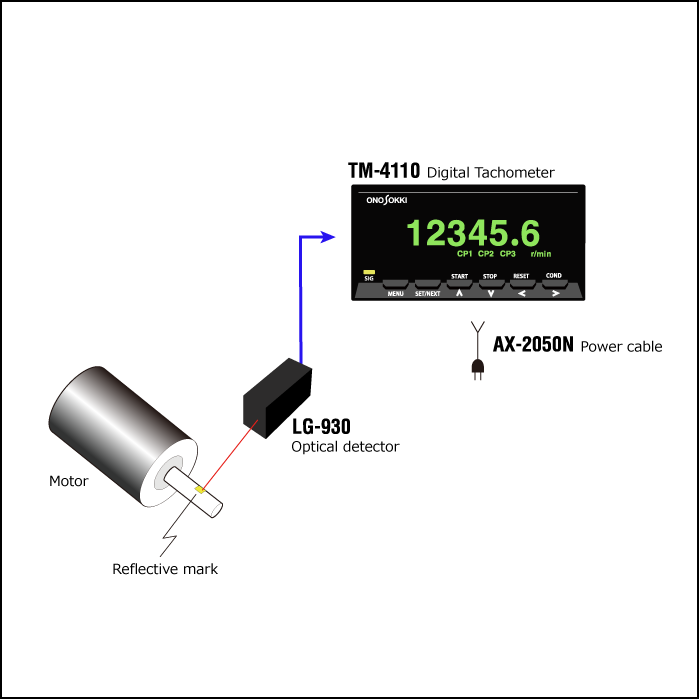

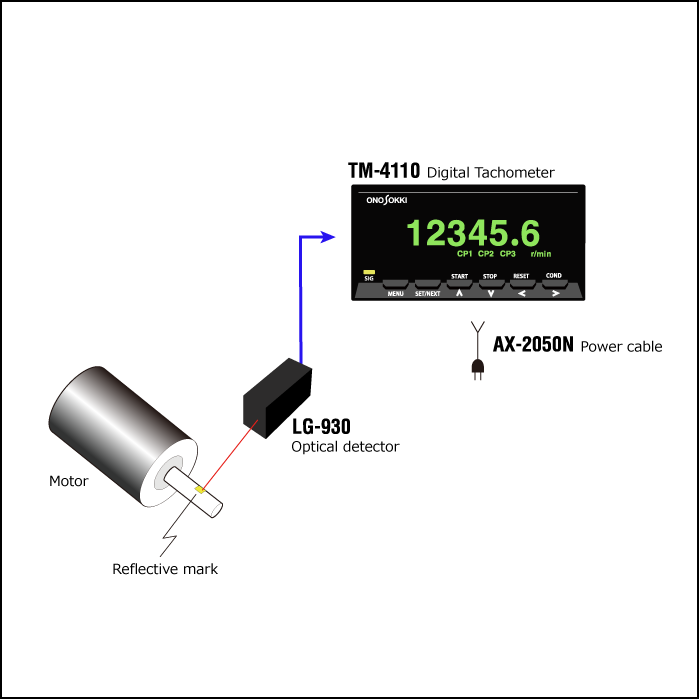

Measuring the rotational speed with Non-contact type optical detector-2

A-3-1

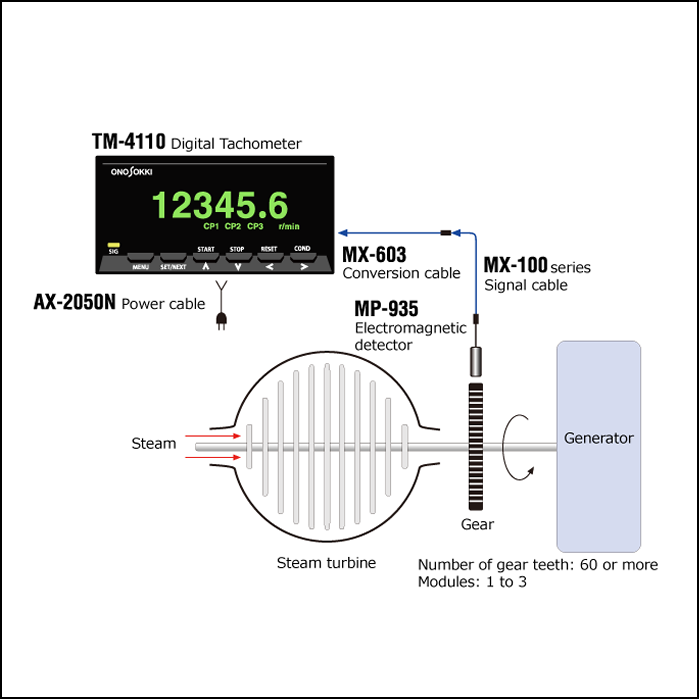

Non-contact measurement of rotational speed using oil and heat proof detector

Detection of rotational speed from rotational shaft

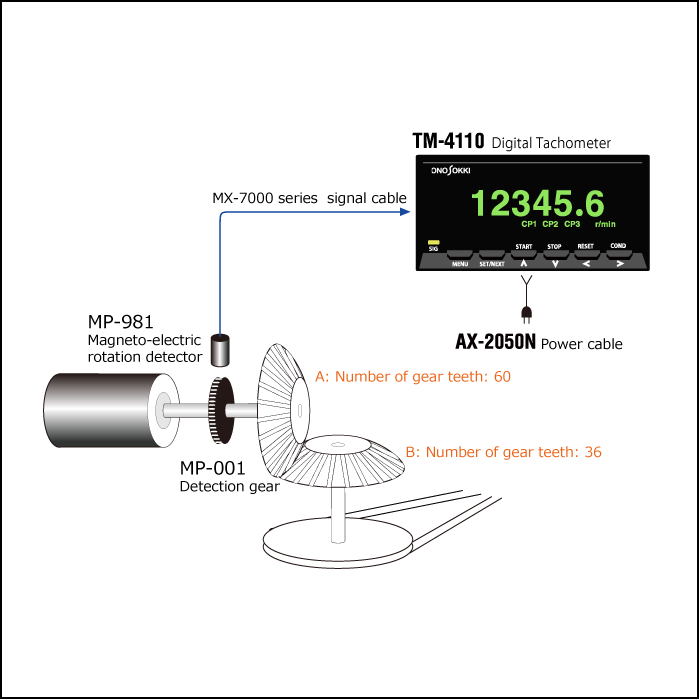

A-4-1

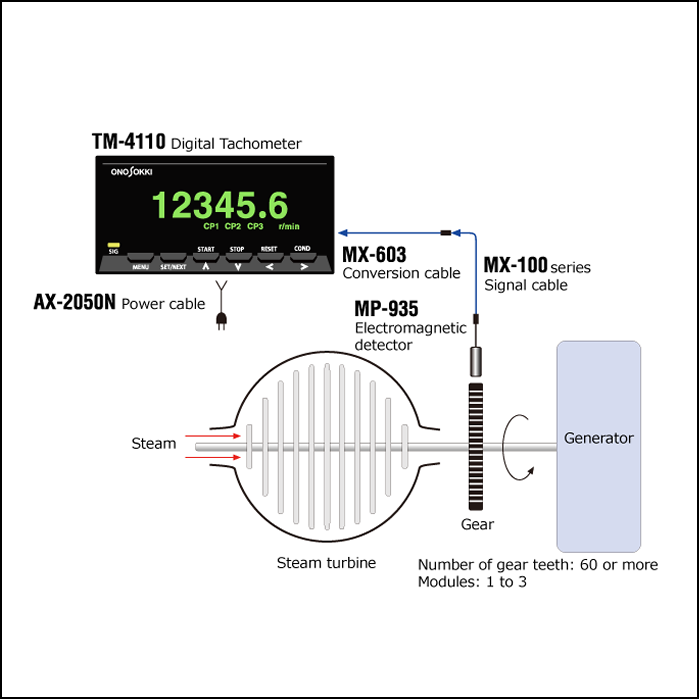

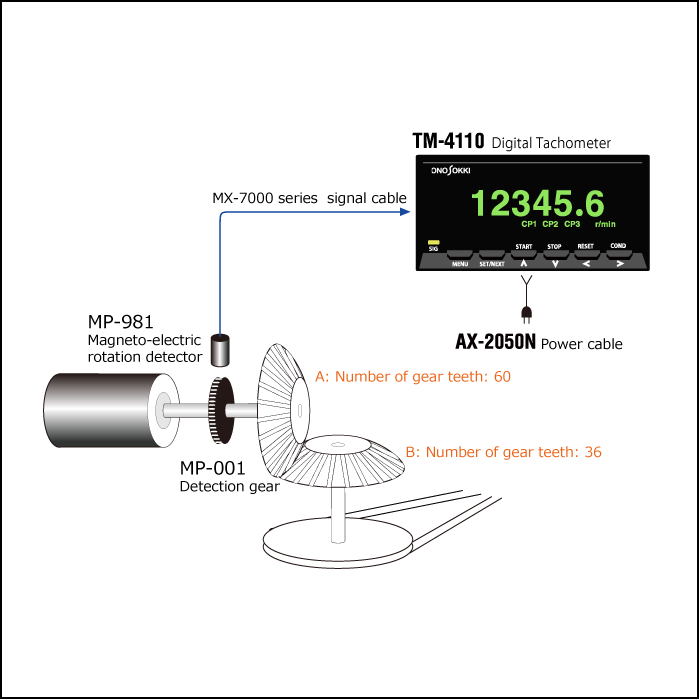

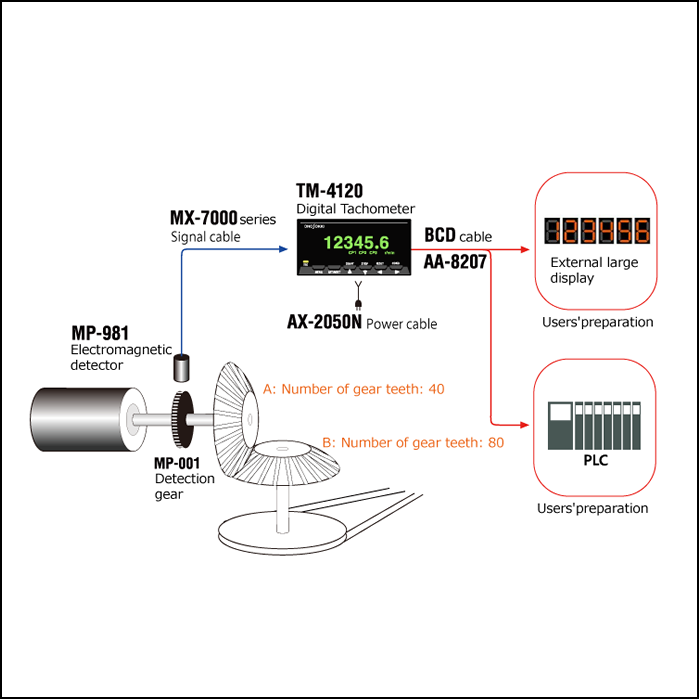

Rotational speed measurement of load side from the side of driving gears

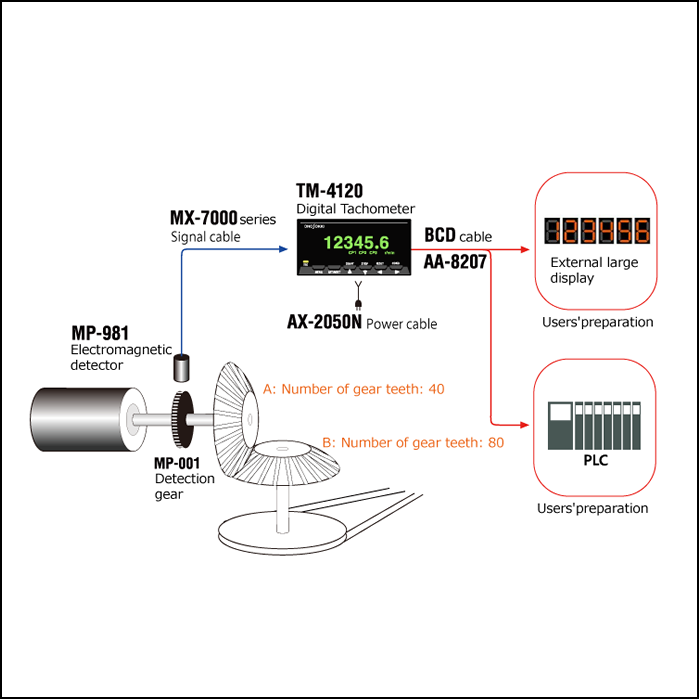

A-4-2

Measuring and indicating rotational speed of shaft, outputting the measurement results to printer or sequencer

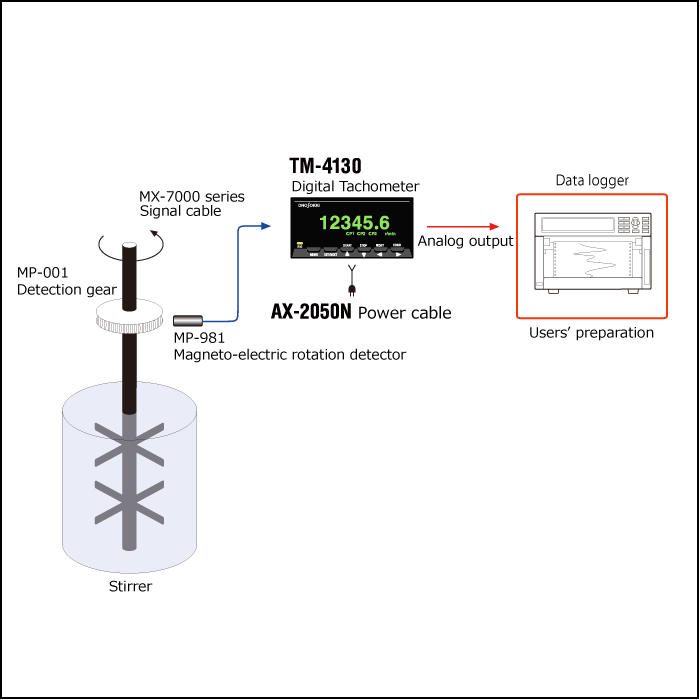

A-4-3

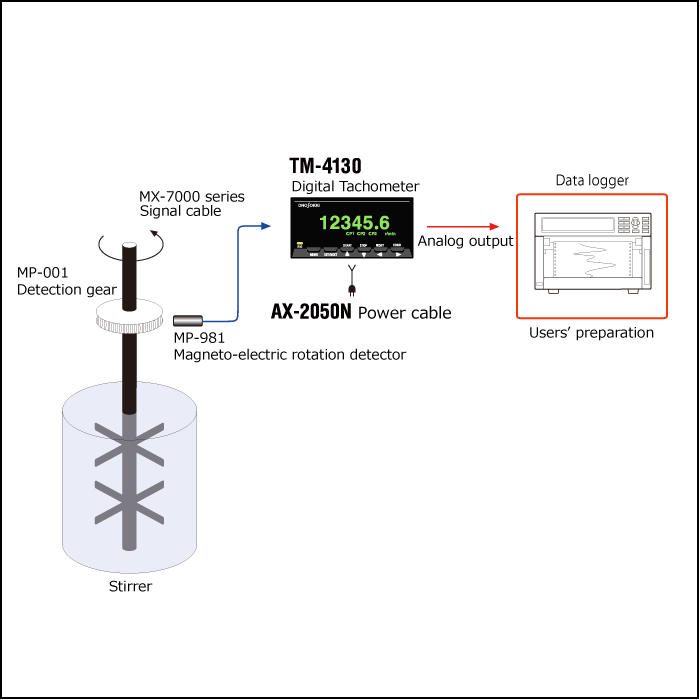

Measuring and indicating the rotational speed of shaft, recording its rotational fluctuation

A-4-4

Measuring the rotational speed at low-speed

Measurement of rotational fluctuation

A-5-2

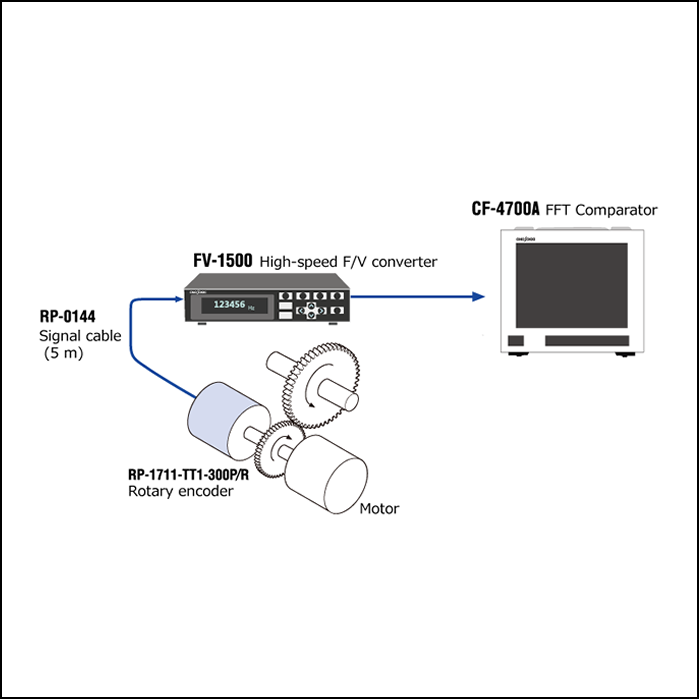

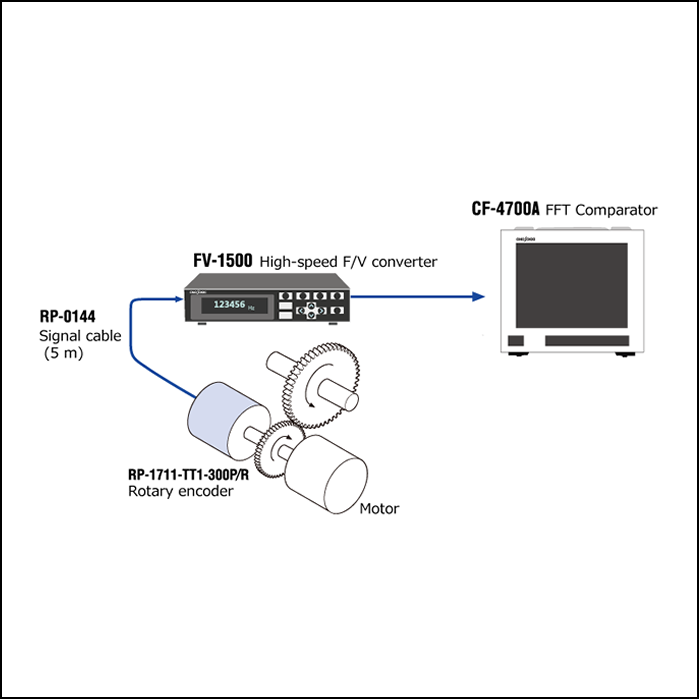

Analyzing the fluctuation of rotational speed ( High response type)

Measurement of rotational speed when the rotating shaft is not come out.

(Rotational detection from sound & vibration)

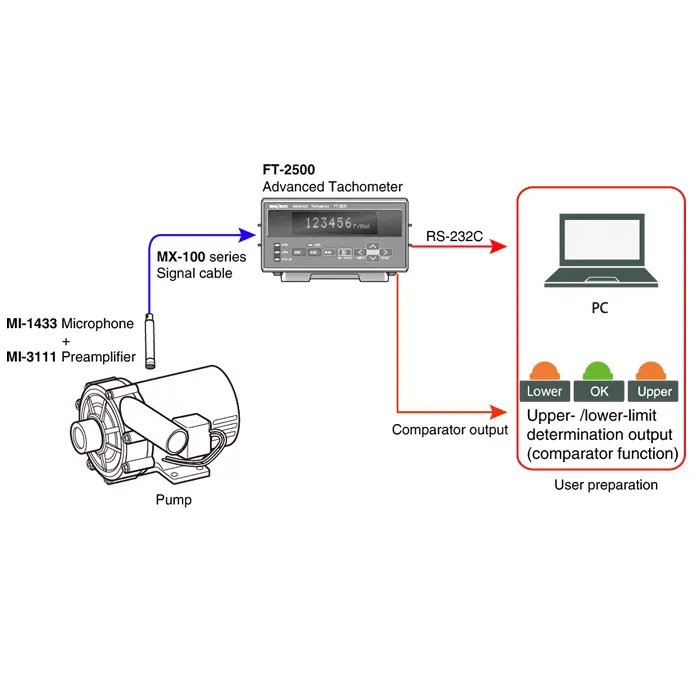

B-1-1

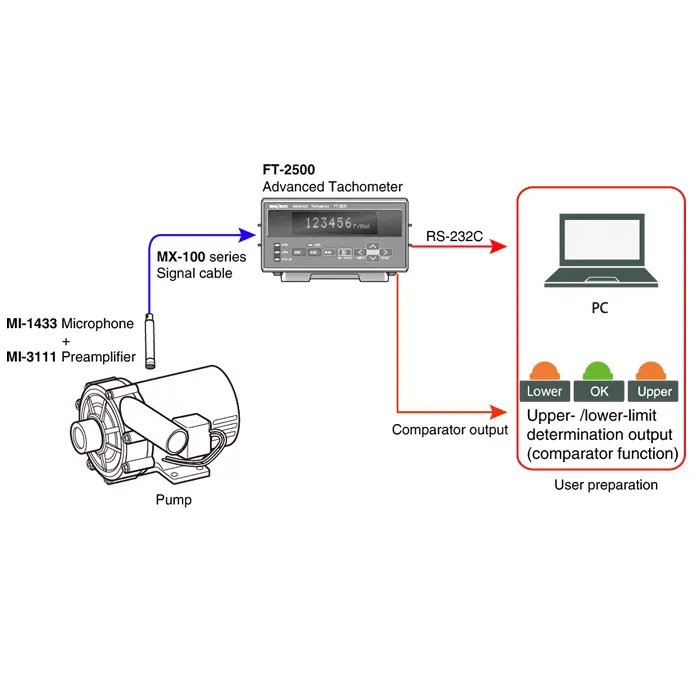

Measuring the rotational speed of a pump from sound (noise)

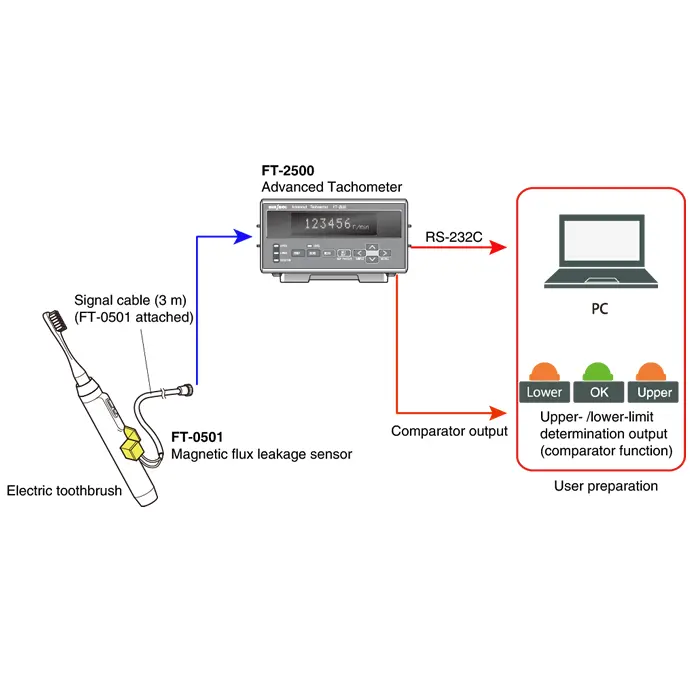

B-1-2

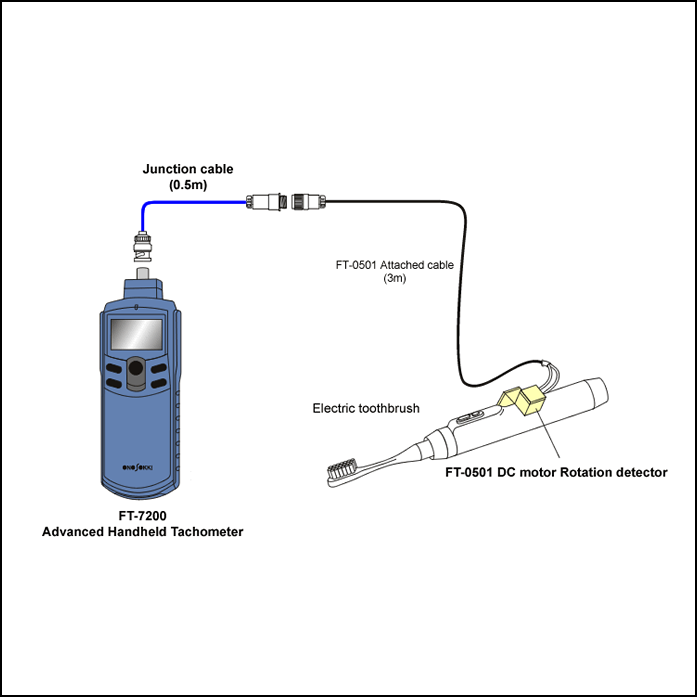

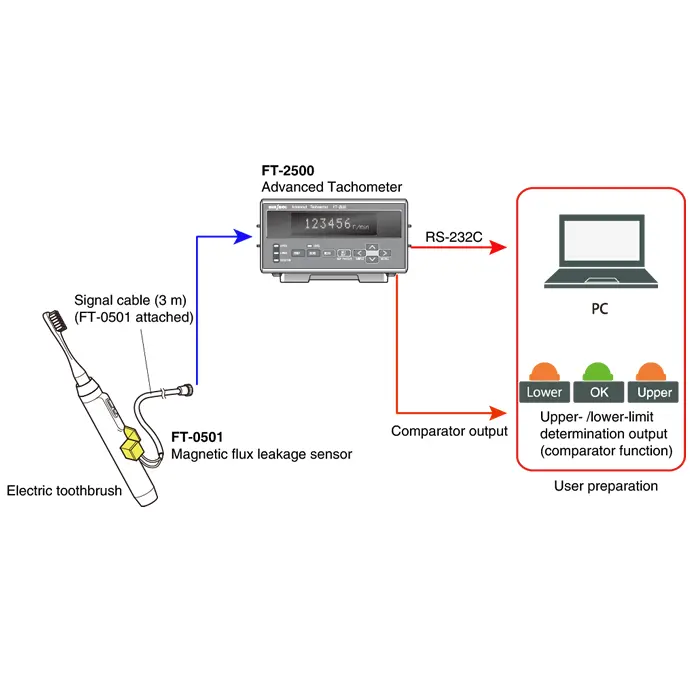

Measuring the rotational speed of DC motors built-in products

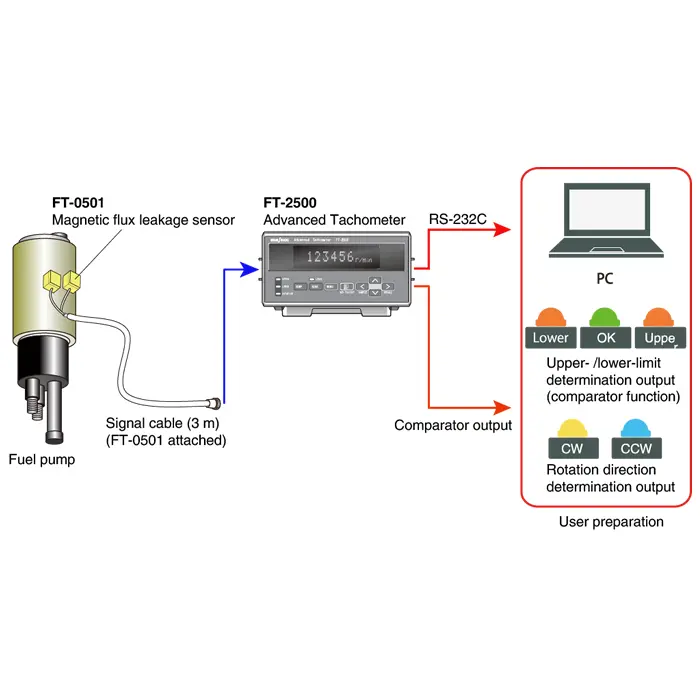

B-1-3

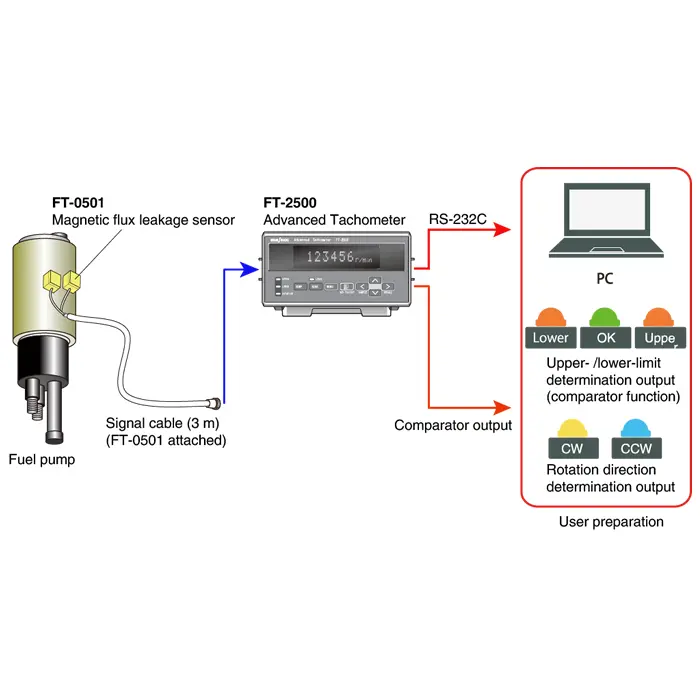

Simultaneous measurement of rotating speed and direction of a fuel pump

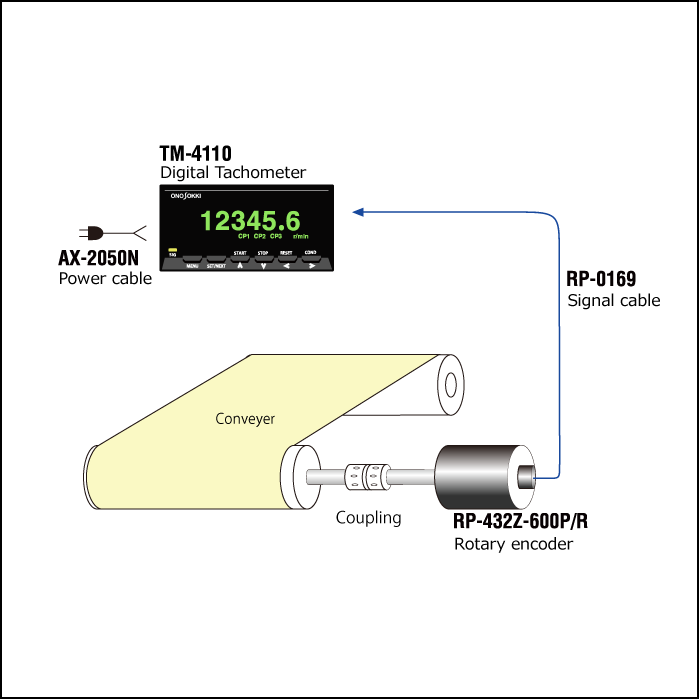

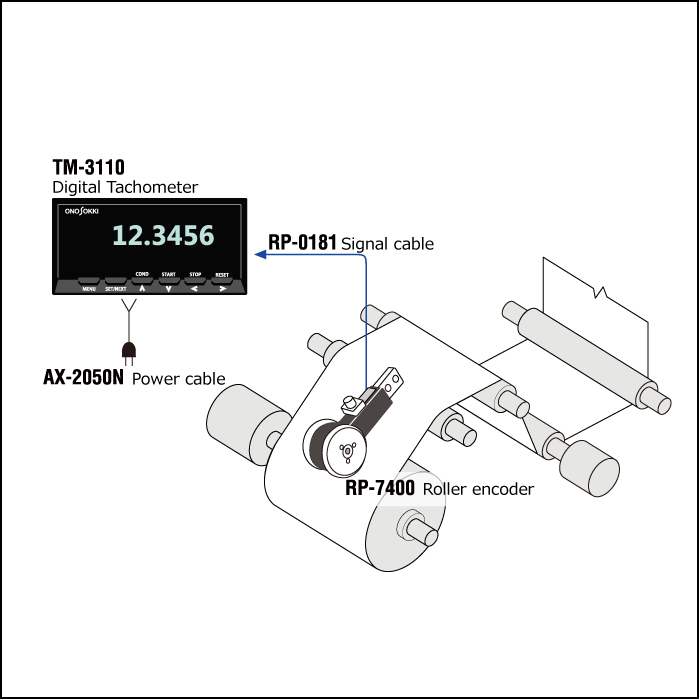

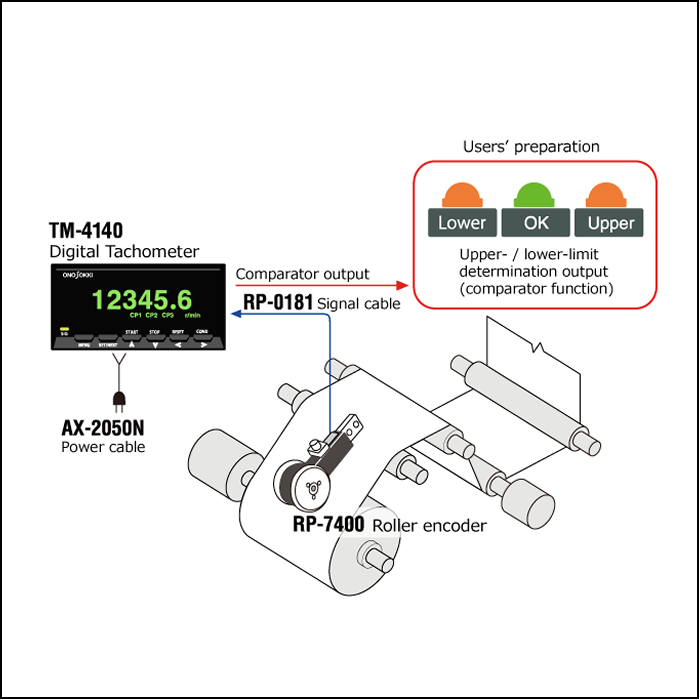

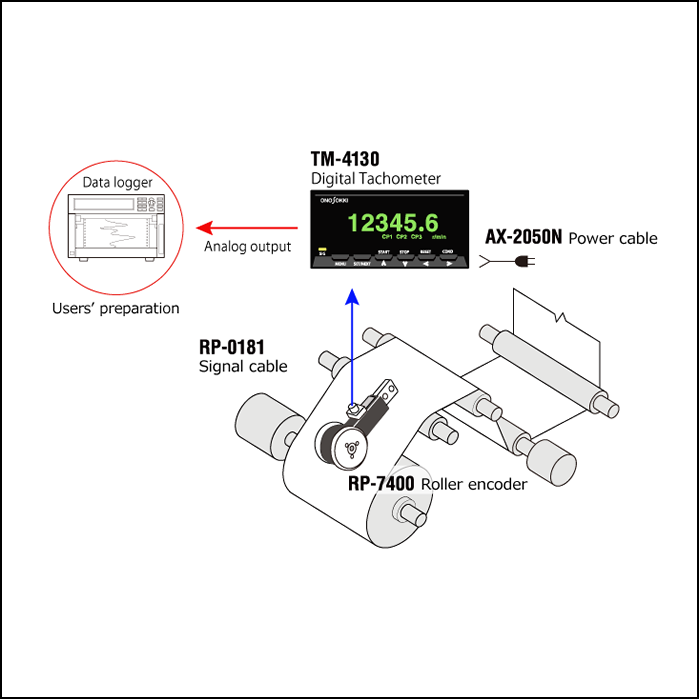

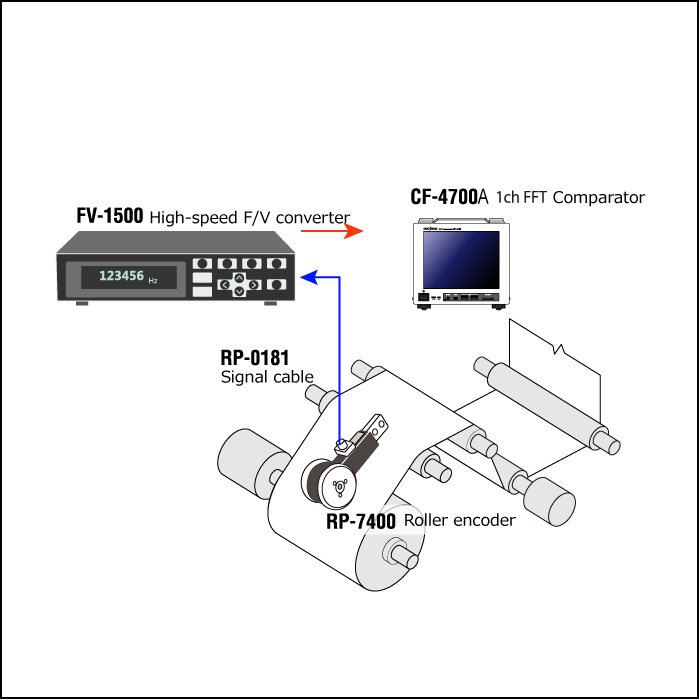

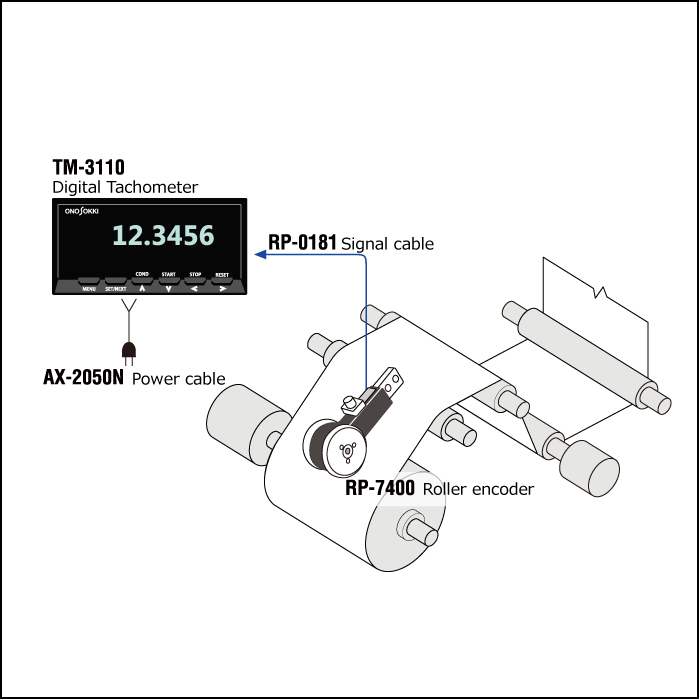

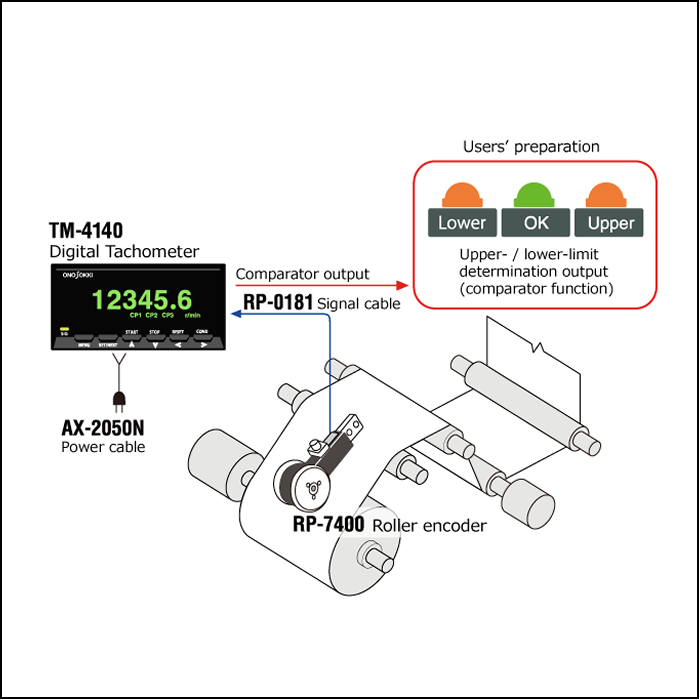

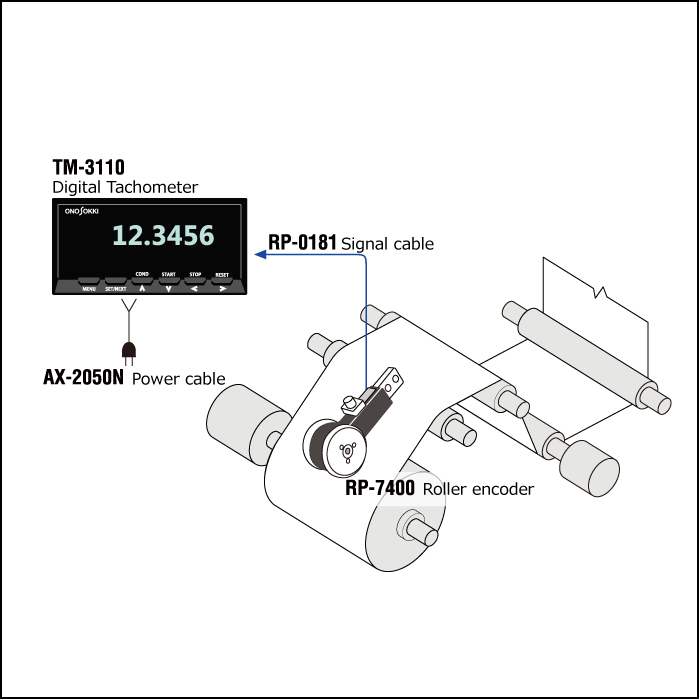

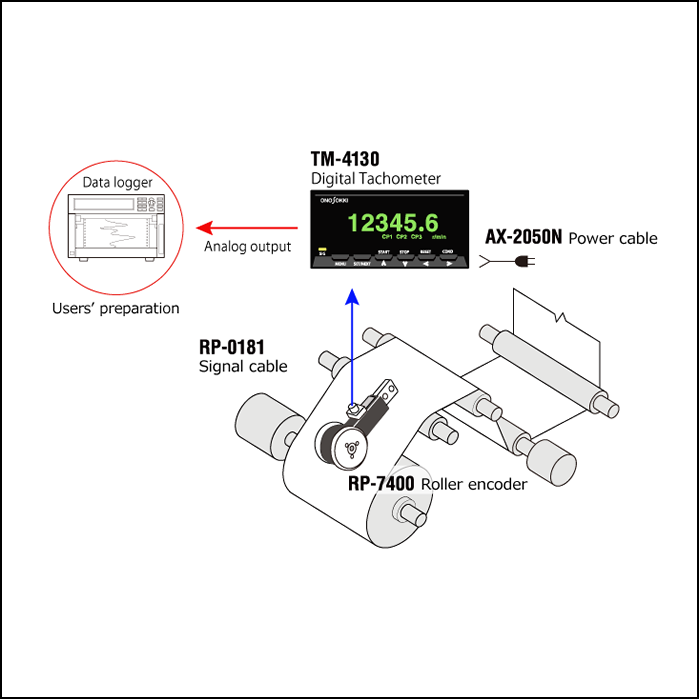

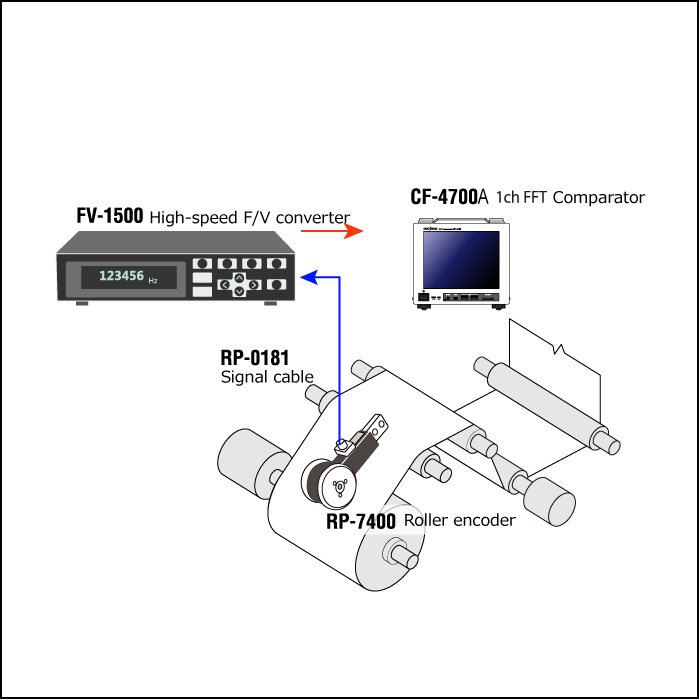

Measurement of rotational speed on production line (with Roller encoder)

C-1-1

Measuring the line speed at low-speed (measurement range 0.01 to 200 m/min)

C-1-2

Measuring the line speed at medium-speed and alarming when the line speed

exceeds the set range (measurement range 0.1 to 200 m/min)

C-1-3

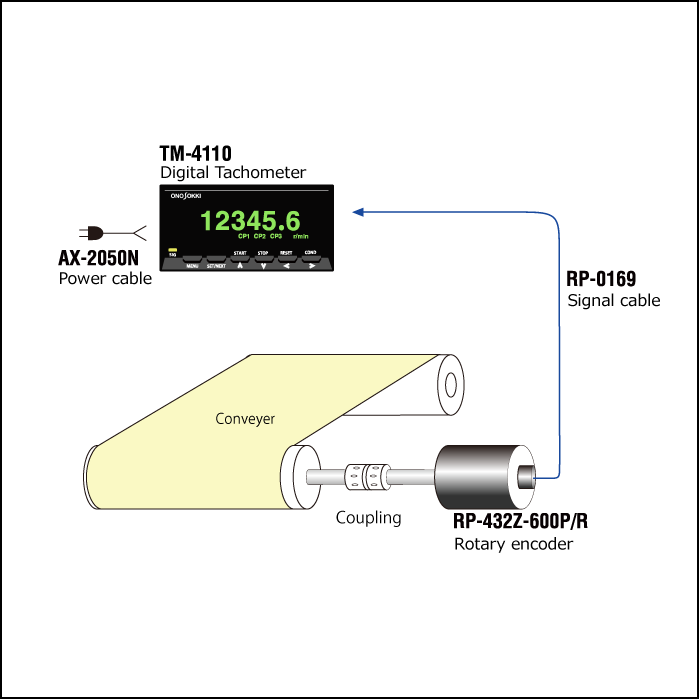

Measuring the line speed at medium and high-speed

(measurement range 0.1 to 600 m/min)

C-1-4

Measuring the line speed and recording the fluctuation of line speed

C-1-5

Analyzing the fluctuated speed (high-speed response type)

Others

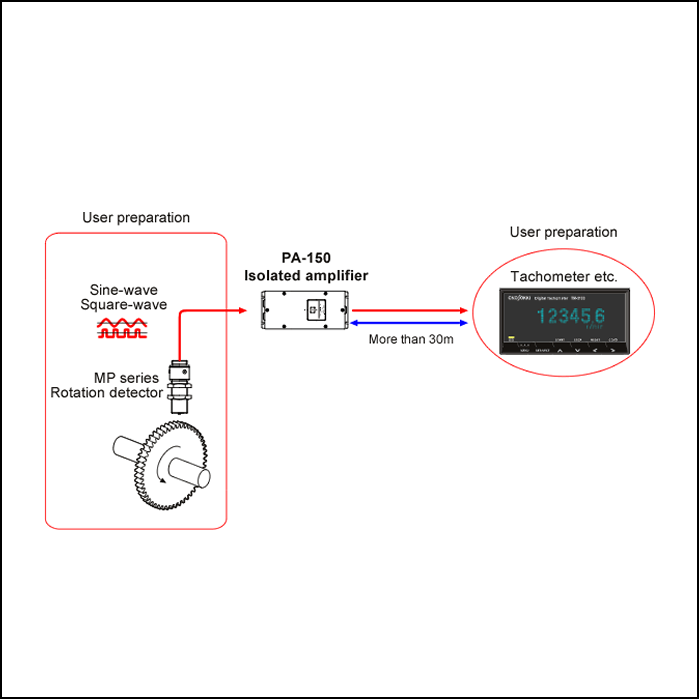

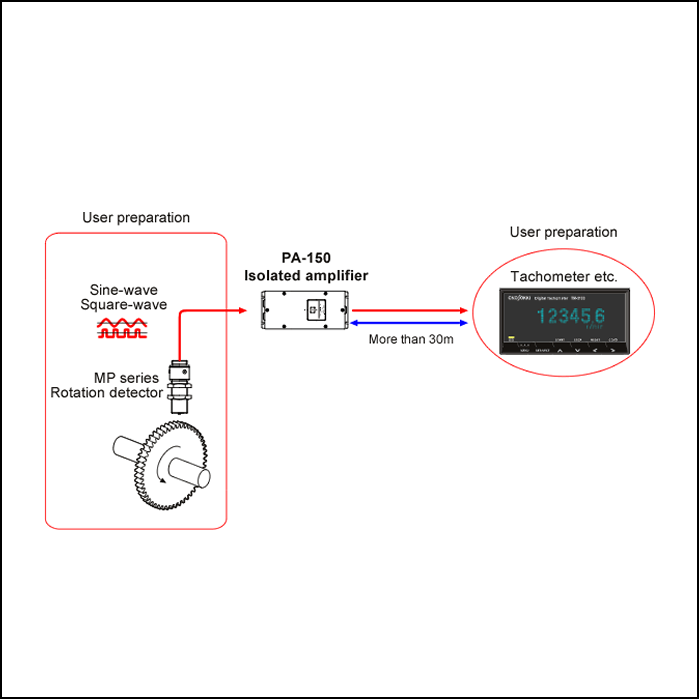

E-1-1

Transmitting a signal from rotational detector (electromagnetic type/magnetoelectric type) over long distance more than 30 m

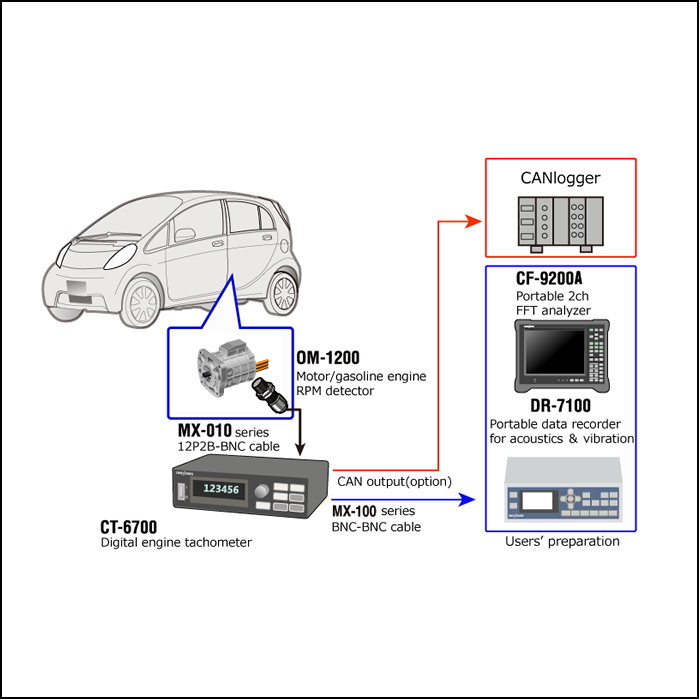

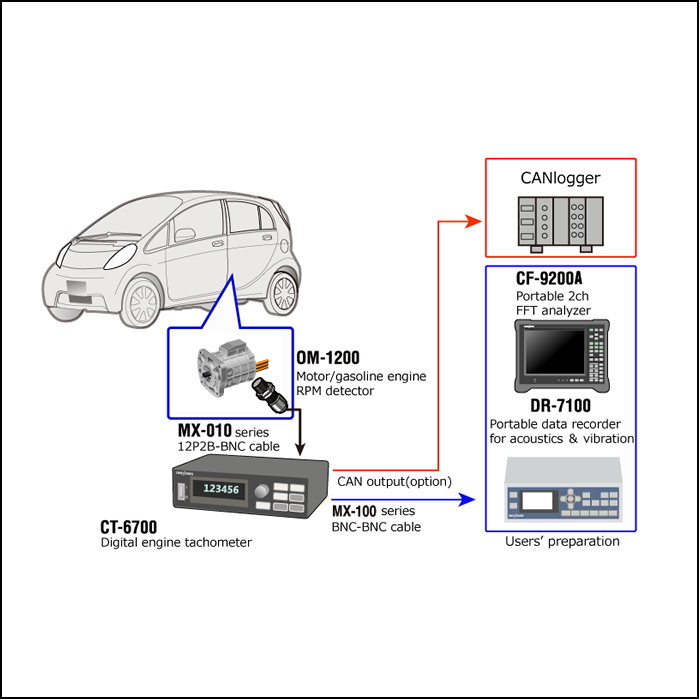

E-1-3

Measurement of rotation speed of DC motor on EV

No-load / non-contact velocity measurement by laser

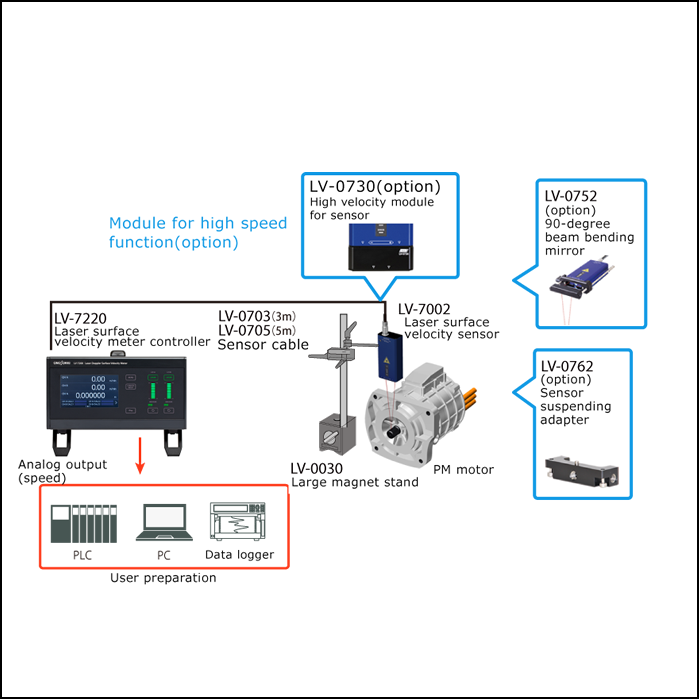

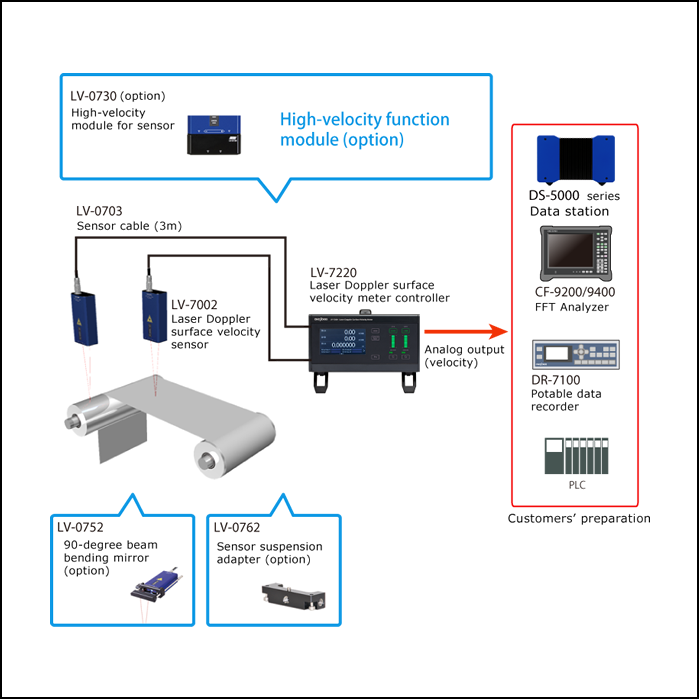

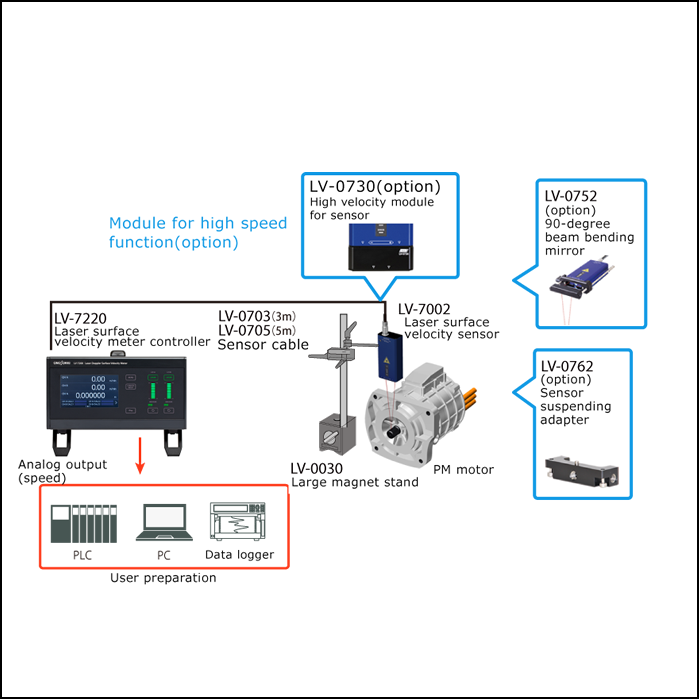

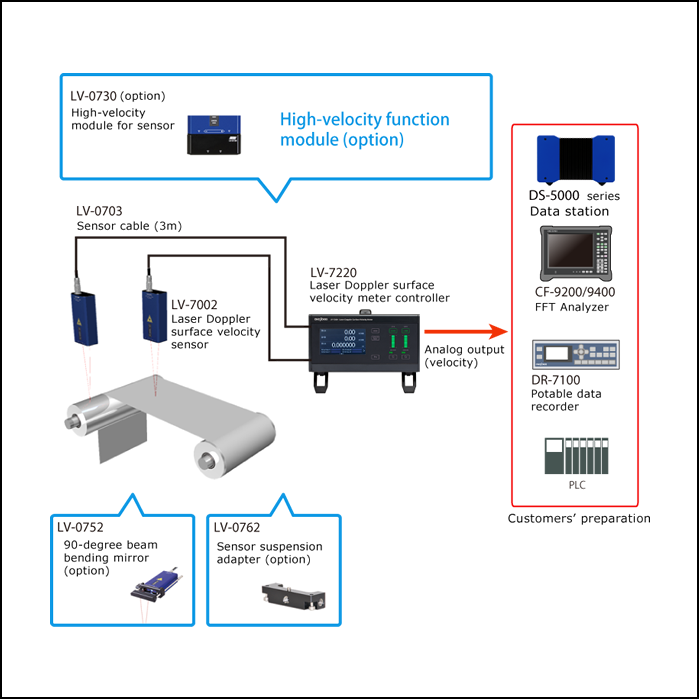

F-1-1

Measurement of motor rotation speed

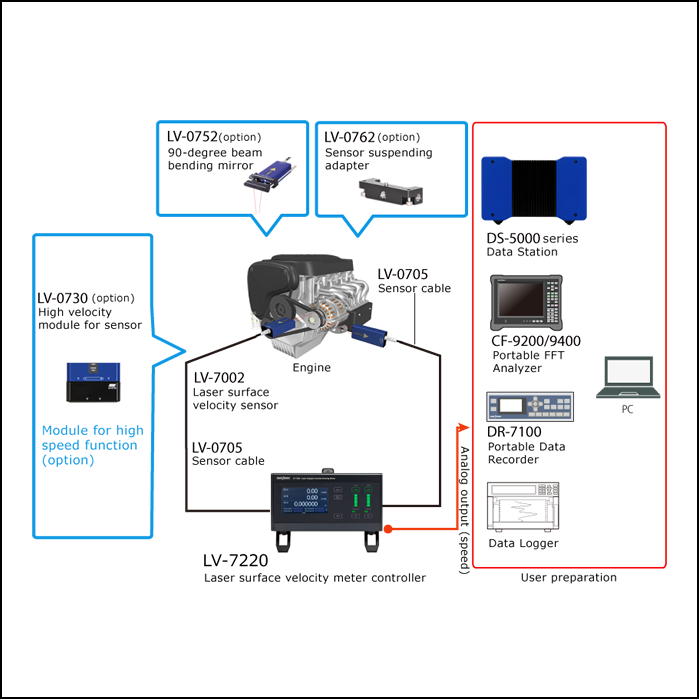

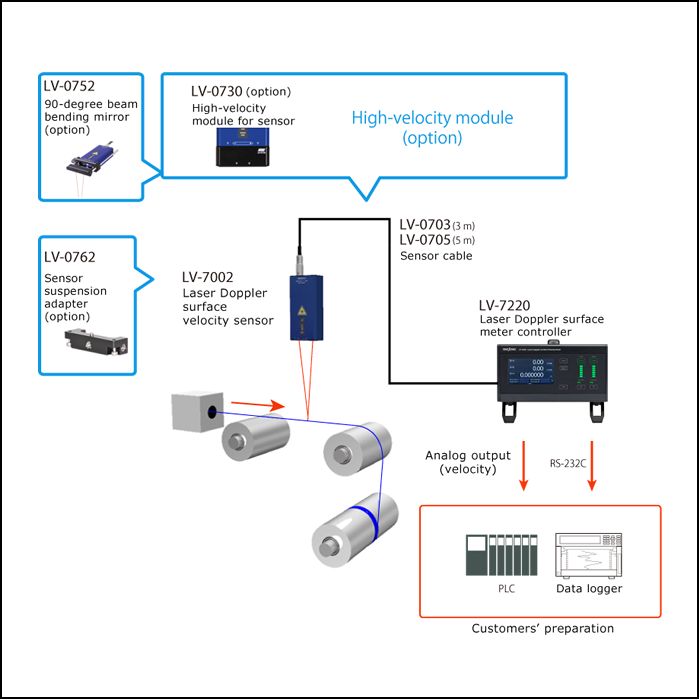

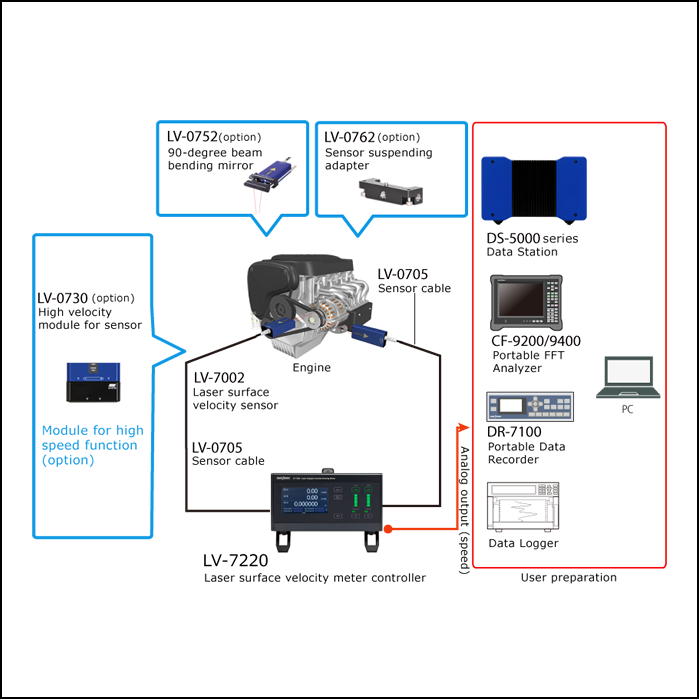

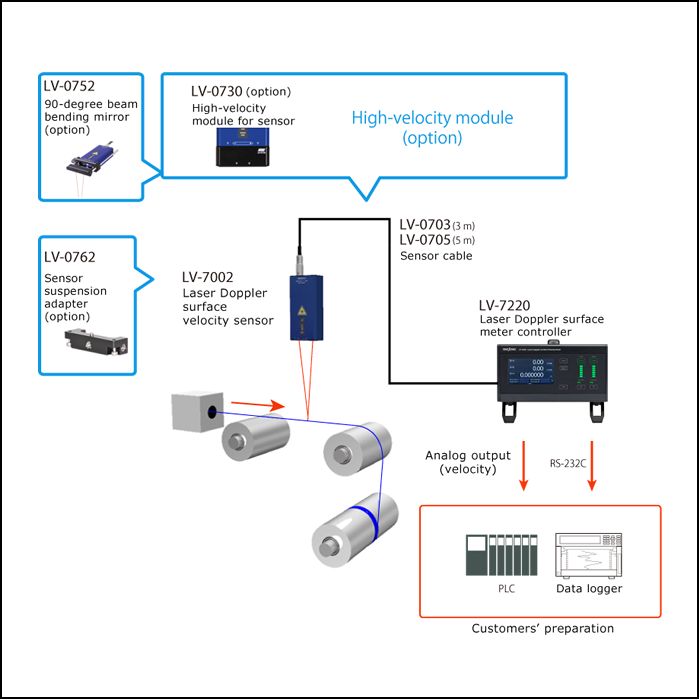

F-1-2

Measurement of behavior, speed fluctuation, and slip for crank pulley/belt

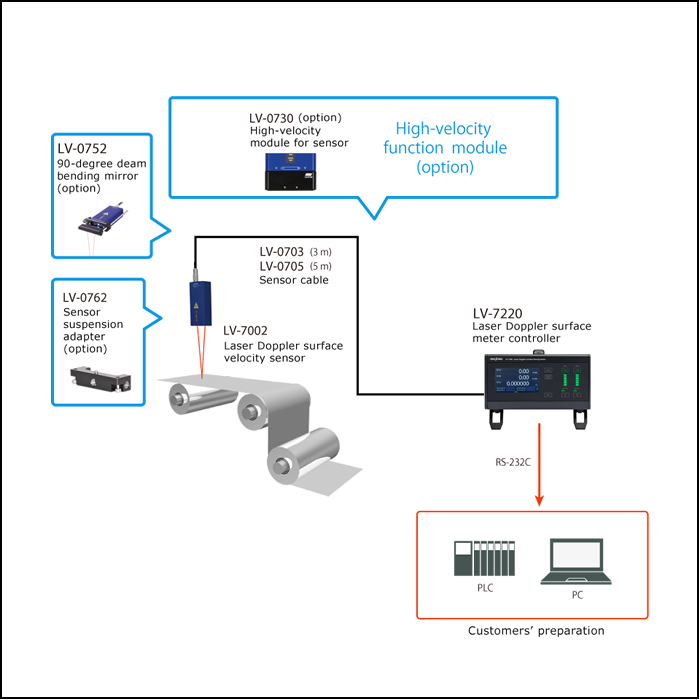

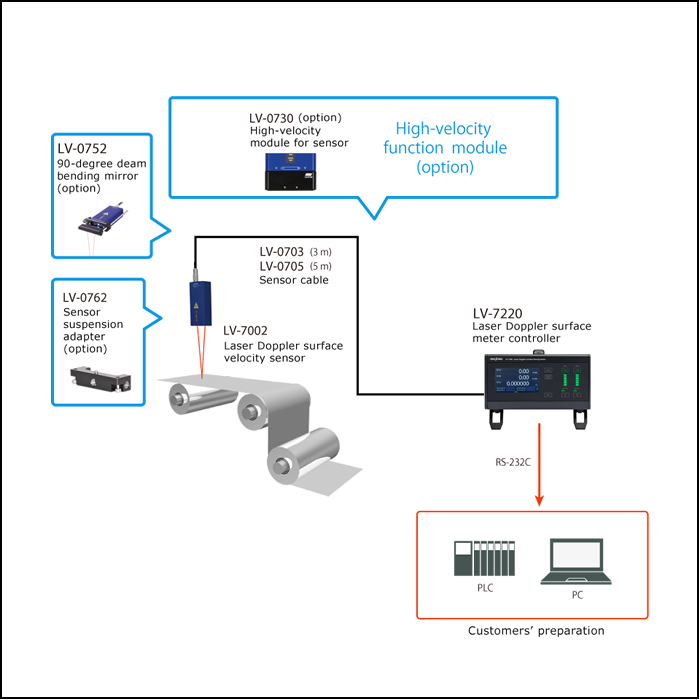

F-1-3

Measurement of Conveyance Slip with Delivery Roll

F-1-4

Measurement of Velocity and Length of Wire/Wire Rod

F-1-5

Measurement of Length and Distance of Material/ Finished Product