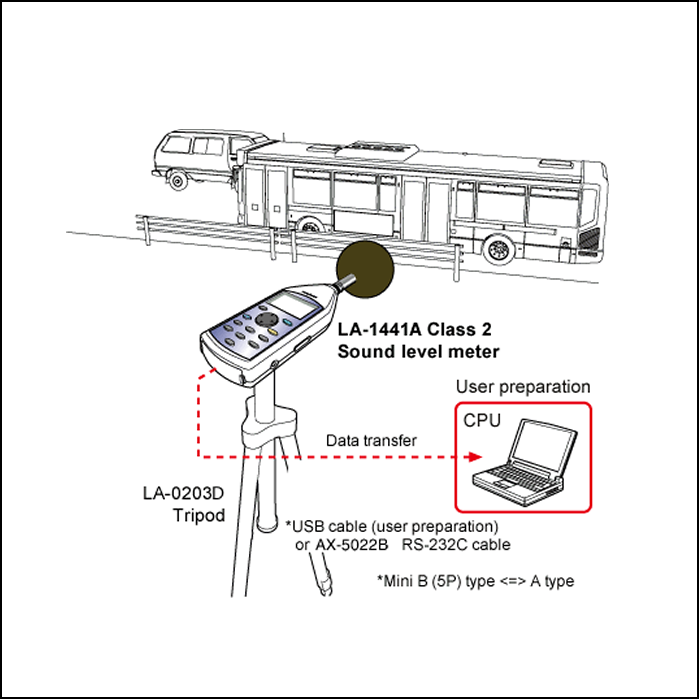

A-2-1

Measurement of traffic noise (integrating sound level meter in used)

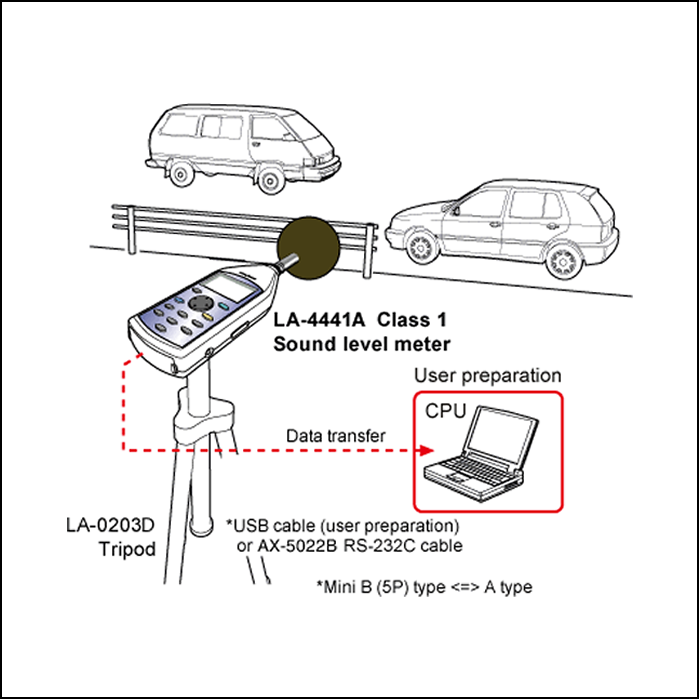

A-2-2

Measurement of traffic noise (precision integrating sound level meter in used)

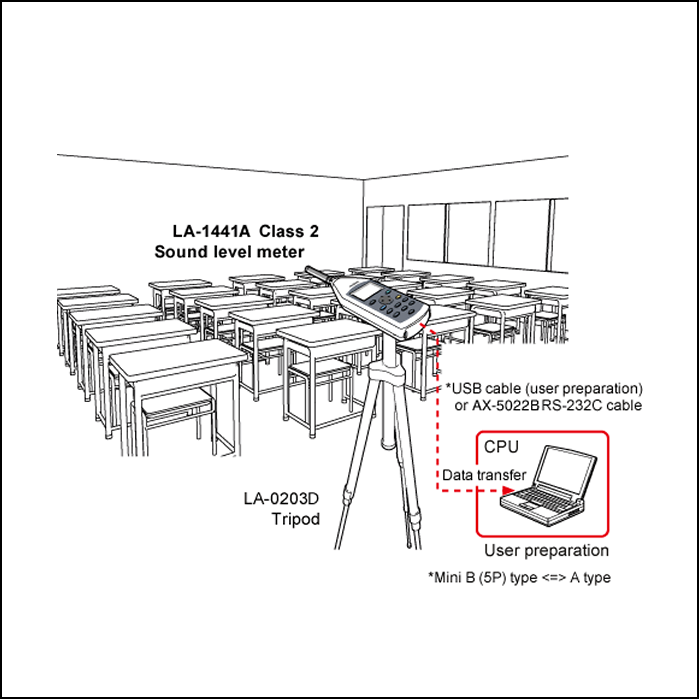

A-2-3

Sound measurement in the classroom

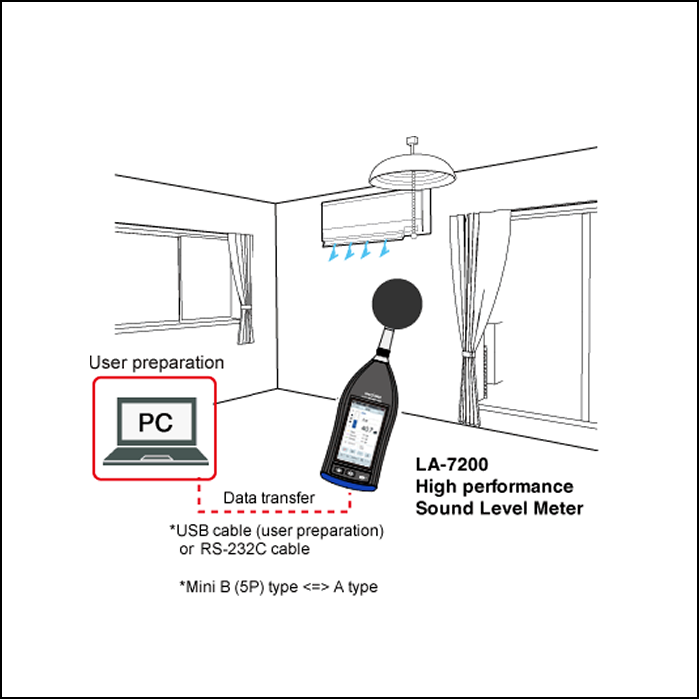

A-2-4

Measurement of NC value in the air-conditioned room

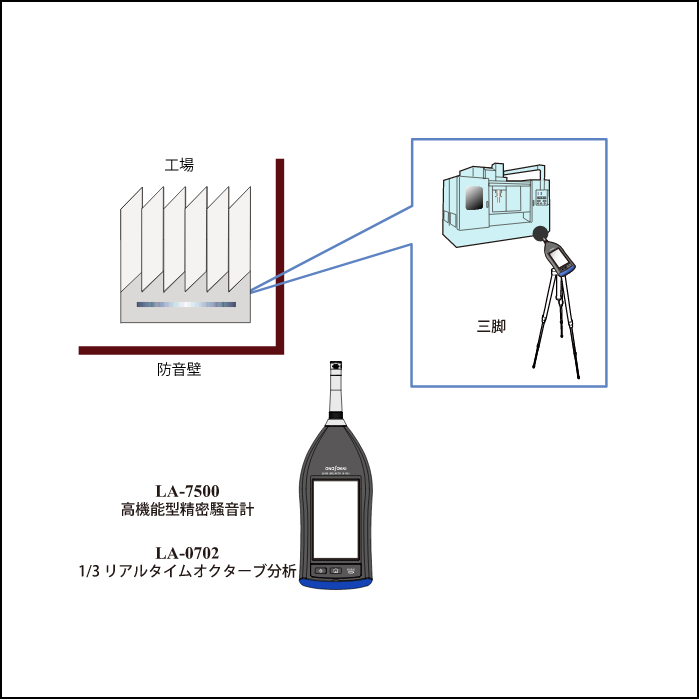

A-2-5

Soundproofing measures

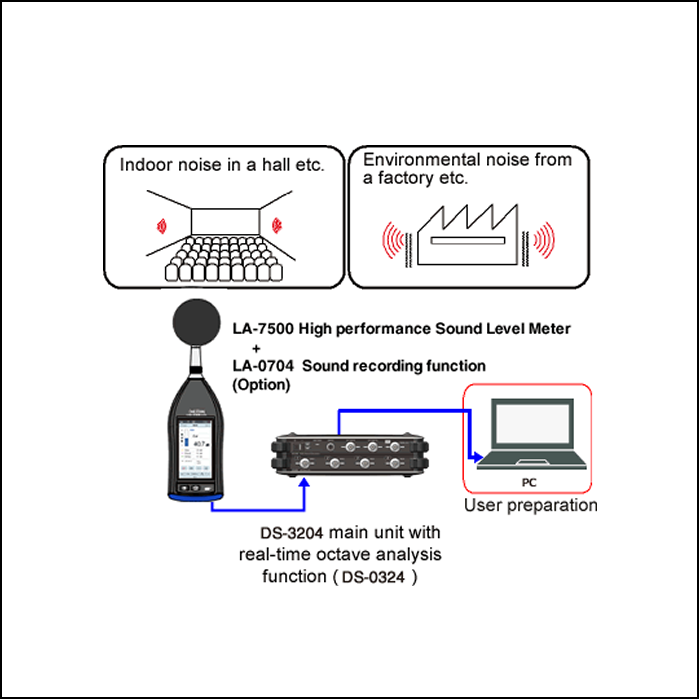

A-2-6

Sound level measurement and real-time octave analysis in a factory or hall

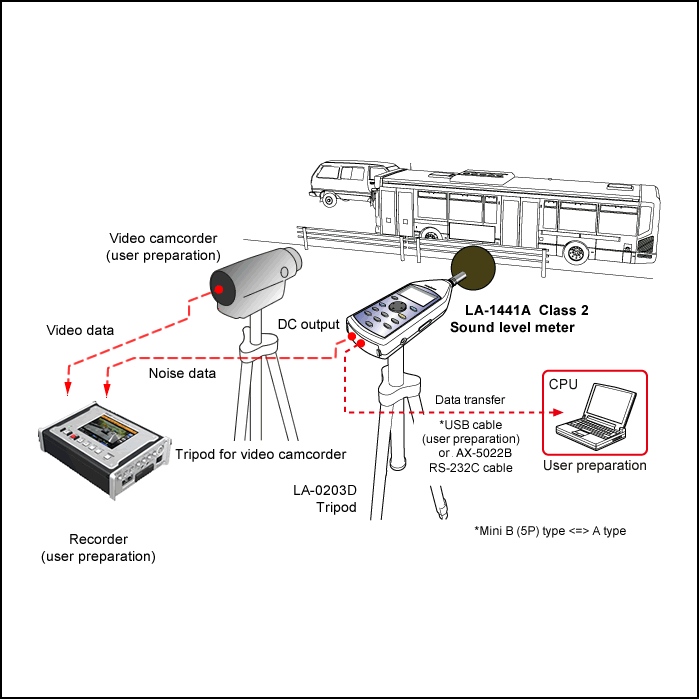

A-2-7

Measurement of traffic noise(simultaneous recording of noise and video data by using integrating sound level meter and video data recorder)

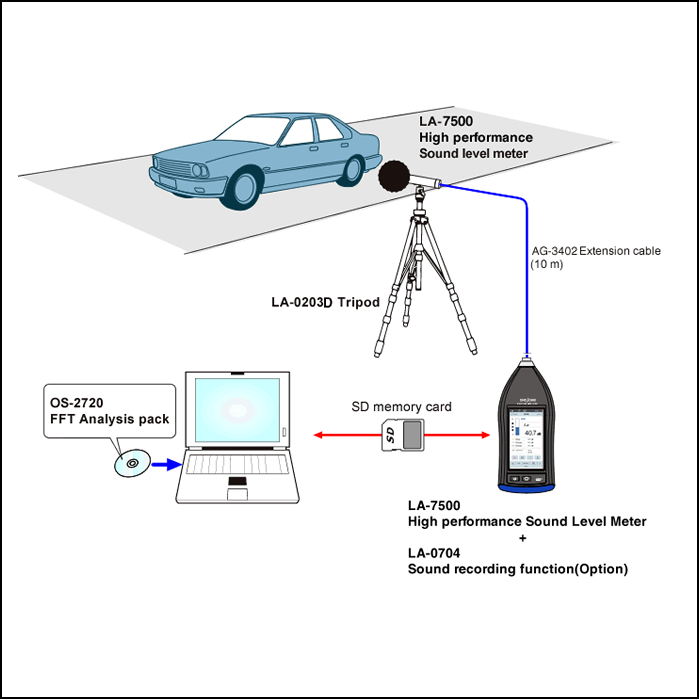

A-2-8

Analysis of noise from a running vehicle

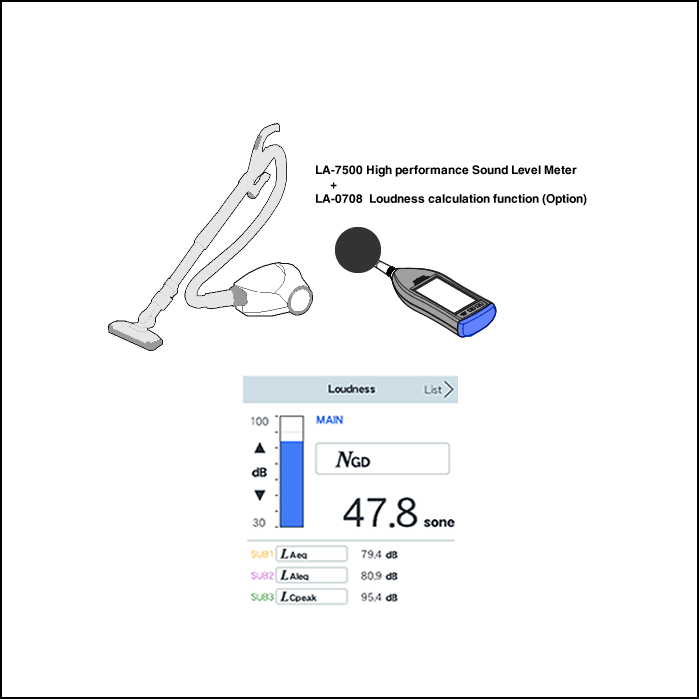

A-3-1

Measurement of loudness from home appliances

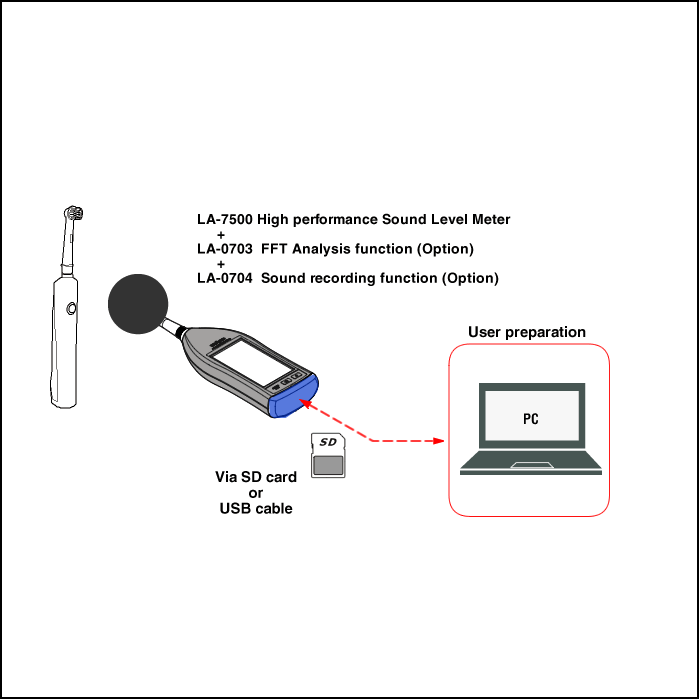

A-3-2

Performing FFT analysis of noise which is generated from home appliance-1

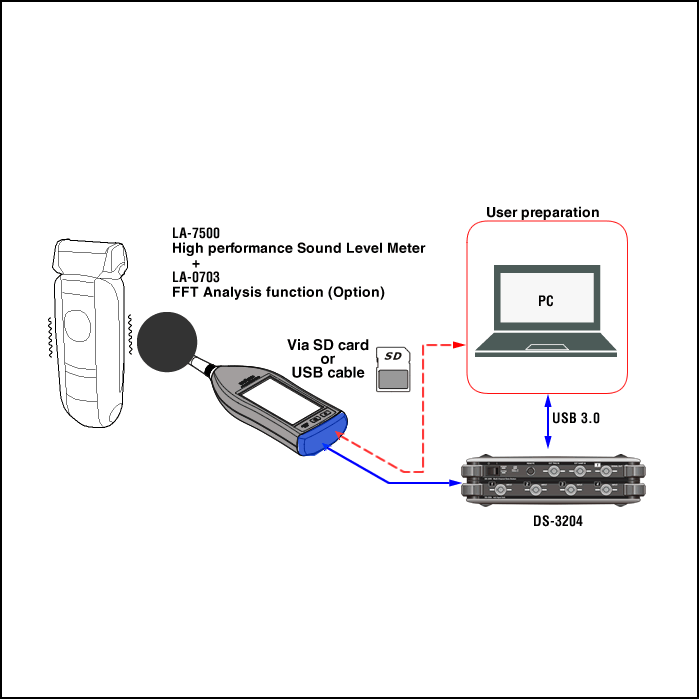

A-3-3

Performing FFT analysis of the noise which is generated from home appliance-2

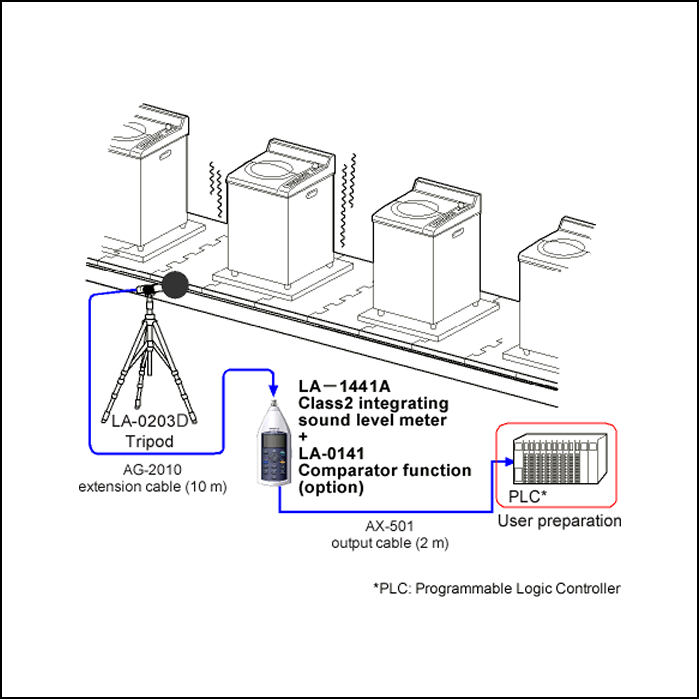

A-3-4

Analysis and OK/NG determination of noise on the production line

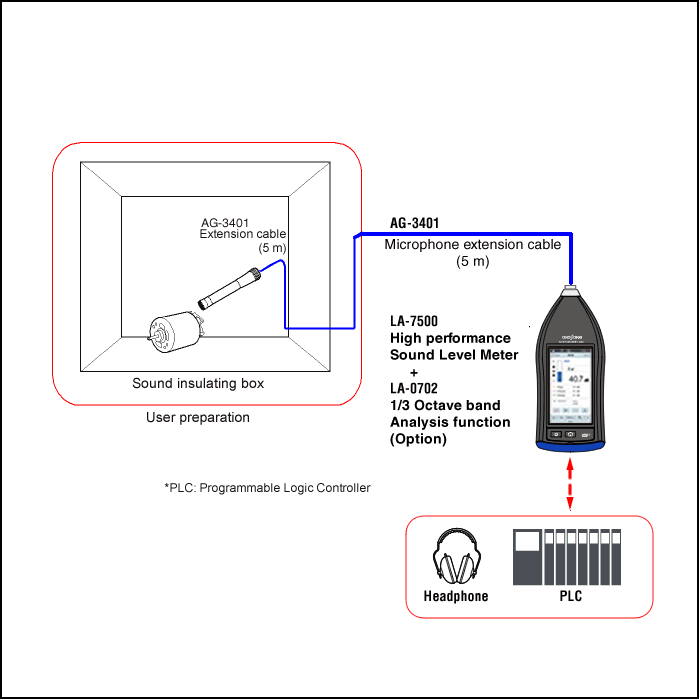

A-3-5

Analysis and OK/NG determination of noise from compact motor

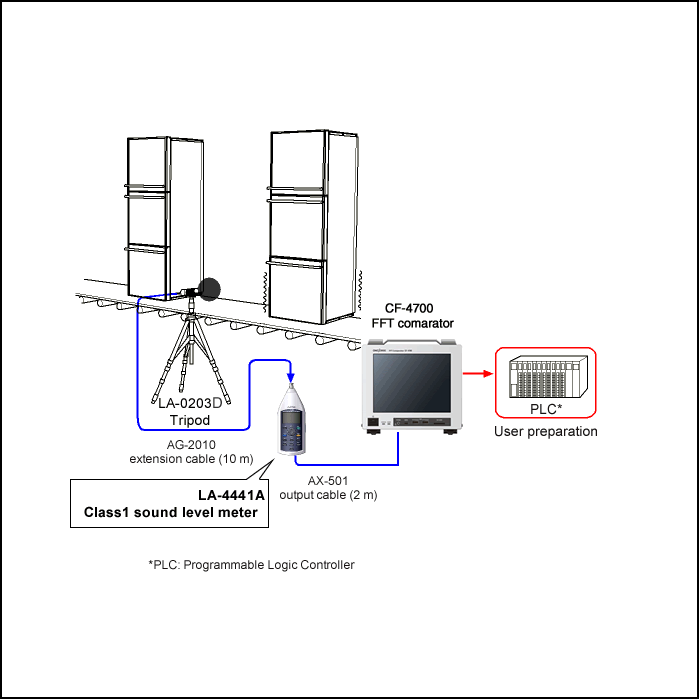

A-3-6

FFT analysis and OK/NG determination of noise from home appliance

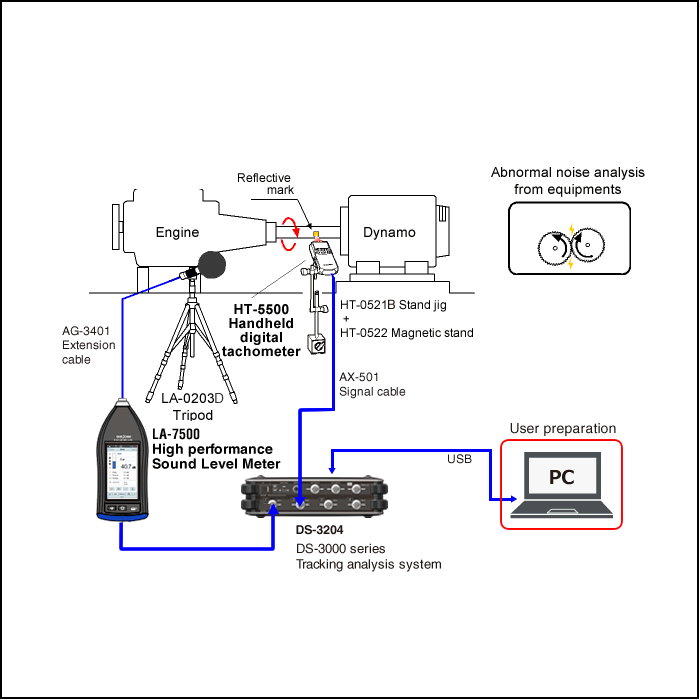

A-3-7

Tracking analysis of sound and vibration from the rotation machine