Ono Sokki has been providing various kinds of vibration related products to meet versatile requirements beginning with accelerometers which are trigger for detecting vibration, impulse force hammer used for natural frequency measurement, laser doppler vibrometer for high-sensitivity vibration measurement and analyzers for the obtained vibration data etc. We offer comprehensive support system for vibration measurement and analysis with various applications to suit your needs.

Structures and operating principles of accelerometers

External force generates electric changes on the surface of such materials as single crystal and barium titanium. This is called piezoelectric effect, and such materials are called piezoelectric materials (piezoelectric elements). A piezoelectric accelerometer uses a piezoelectric element as a spring for a seismic system and a mechano-electrical transducer.

This sensor outputs an electric signal proportional to vibration acceleration. The piezoelectric accelerometer is classified by the force applying direction into two major types: compression type and shear type. The figures above show their structures; the compression type has a piezoelectric element located between a sensor base and an internal mass. The shear type has a piezoelectric element fixed between a post perpendicular to a base and an internal mass. The compression type was popular in the past, but the shear type has pervaded recently because of immunity to base distortion and rapid changes in temperature. Most of our piezoelectric accelerometer is of the share type.

| Vibration analysis / Diagnostic related products | |||||

|---|---|---|---|---|---|

| Record | Analysis | Judgement | |||

DS-3200 Data Station |

CF-4700A FFT Comparator |

VC-2200/3200 Vibration Comparator |

|||

NP series Accelerometers

Operating principle of Laser Doppler Vibrometer

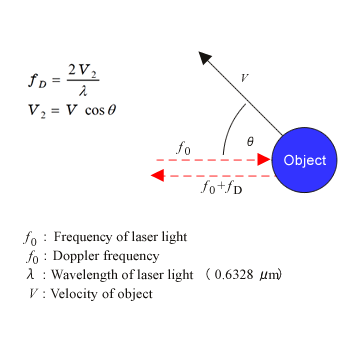

If an acoustic, radio or light wave of a specific frequency is beamed at a moving object, the frequency of the wave reflected from the moving object differs in proportion to the velocity of the object. This phenomenon is known as Doppler shift or the Doppler effect. The relationship between the frequency at which the wave is beamed and the frequency at which the wave echoes is outlined below.

If the object is approaching the source, the reflected frequency is higher than the emitted frequency. Emitted frequency < Reflected frequency

If the object is receding from the source, the reflected frequency is lower than the emitted frequency. Emitted frequency > Reflected frequency

The laser Doppler vibrometer is based on this principle. When laser light is beamed at a moving object, the frequency of the laser light reflected from the object differs from the original frequency of the emitted laser light due to this Doppler effect. The vibrometer considers the amount of Doppler shift generated. Given that the change in frequency is fD, the velocity of the moving object is V, the wavelength of the emitted laser light is λ, and the angle between the direction in which laser light runs and the direction in which the object moves is θ, then the above equation holds true. As shown in the figure above, the frequency of the reflected laser light is f0+fD. Since the wavelength λ used by the laser Doppler vibrometer is extremely stable, the Doppler frequency fD and velocity V are proportional. Normally, the angle θ is set at 0 (only the component of reflected light parallel to incident light--out-of-plane vibration*--is detected) and, therefore, the velocity of the object moving in the direction of the emitted laser light can be determined by measuring fD. The frequency of laser light is so high, however, that it is extremely difficult to measure directly. For this reason, fD is normally determined by allowing the emitted laser light (f0) to interfere with the reflected laser light (f0+fD).