Roller Encoders RP-7400 series

General-purpose type

Ideal for linear measurement of moving objects

Conforms to RoHS, CE marking

Speed measurement:120 P/R 1200 P/R

Length measurement:200 P/R

Easy measurement by only pressing the roller against moving object.

Anti-slip roller which is made of urethane-coating hard rubber

Using with the TM-4100 series enable direct reading of speed measurement without complicated calculation.

Speed measurement can be performed with 0.01 m/min (1200 P/R).

Length measurement can be performed with 1 mm/pulse (200 P/R) in combination of TM-4300 series.

Application example

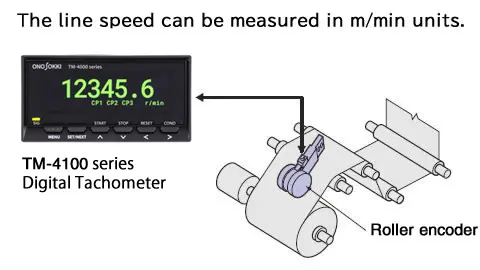

Measurement of line speed

* The signal cables between roller encoder and tachometer are required (sold separately).

| Roller encoder | Signal cable | Digital tachometer |

|---|---|---|

| RP-7400 series (speed) | RP-0181 5 m (One side crimp-on terminal) | TM-4100 series |

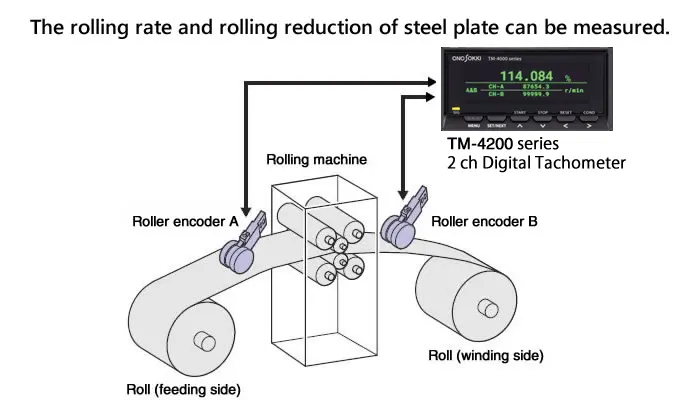

Measurement of rolling rate and rolling reduction

* The signal cables between roller encoder and tachometer are required (sold separately).

| Roller encoder | Signal cable | Digital tachometer |

|---|---|---|

| RP-7400 series (speed) X 2 | RP-0184 5 m (one side ferrule terminal) X 2 | TM-4200 series |

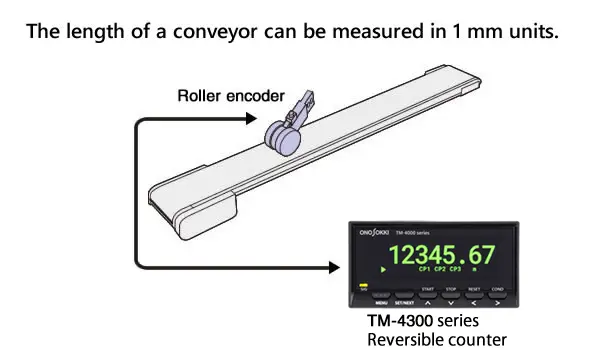

Measurement of conveyor length

* The signal cables between roller encoder and tachometer are required (sold separately).

| Roller encoder | Signal cable | Digital tachometer |

|---|---|---|

| RP-7400 series (length) | RP-0184 5 m (one side ferrule terminal) | TM-4300 series |

Specifications

| Electric Specifications | Output pulse value | Speed | 120,1200 P/R |

|---|---|---|---|

| Length | 200 P/R | ||

| Output waveform | 2 phase square wave | ||

| Duty ratio | 50±25 % | ||

| Phase difference | 90±45 ° | ||

| Output voltage (For DC12 V supply)) |

“Hi”:+10 V or more “Lo”:+0.5 V or less |

||

| Output mode | Totem pole (load resistance 470 Ω or more) | ||

| *Option | RP-0701: Emitter RP-0702: Collector RP-0703: Open Collector |

||

| Supply voltage | DC12 V±5 % (100 mA or less) |

||

| Machine Specifications | Speed range | 0~600 m/min *Above speed range varies depending on conditions of measurement object. |

|

| Roller material | Aluminum + urethane printing (A90 hardness) | ||

| Roller circumference | 200 mm | ||

| Allowed bearing load | Radial:20 N | ||

| Starting torque | 1 mN・m | ||

| Inertia moment | 0.6 kg・cm2 | ||

| Vibration resistance | 19.6 m/s2

X/Y/Z each direction (150 minutes each), 10 to 150 Hz Sweep, 20 cycle |

||

| Shock resistance | 196 m/s2

X/Y/Z each ± both direction (6 ways) 3 times each (total 18 times) sine half wave, reaction time 11 ms |

||

| Mounting holes(position) | φ10 mm x 2 spacing of the center of holes: 20 mm |

||

| General Specifications | Operating temperature range | 0 ~+50 °C (however, no icing or condensation) | |

| Storage temperature range | -10 ~+65 °C (however, no icing or condensation) | ||

| Operating humidity range | Under 35 to 93 %RH (however, no icing or condensation) | ||

| Protection Level | IP40 (when used with optional cable RP-0181, RP-0184) | ||

| Weight | Approximately 400 g | ||

| Accessories | Instruction manual Connector (RM12BPE-5S made by Hirose Electoric Co. Ltd.) |

||

| Applicable cable (option) | For TM-4100 series: RP-0181 (one side crimp-on terminal M3) 5 m For TM-4300 series: RP-0184 (one side ferrule terminal) 5 m |

||

| Applicable counter | Speed | TM-4100 series Digital Tachometer | |

| Length | TM-4300 series Reversible Counter | ||

* TM-4300 series Reversible counter has correction function. Outer circumference error by roller wear can be corrected

* Accumulated error occurs depending on setup condition, roller slipping, or roller wear etc.

* When measuring the moving speed (m / min) with the combination of RP-7400 1200 P/R and FV-1500, set the display unit to "USER".

Related information

Last update : 2023/11/28