Noise Testing Software

GN-1200 series UPDATE 2025

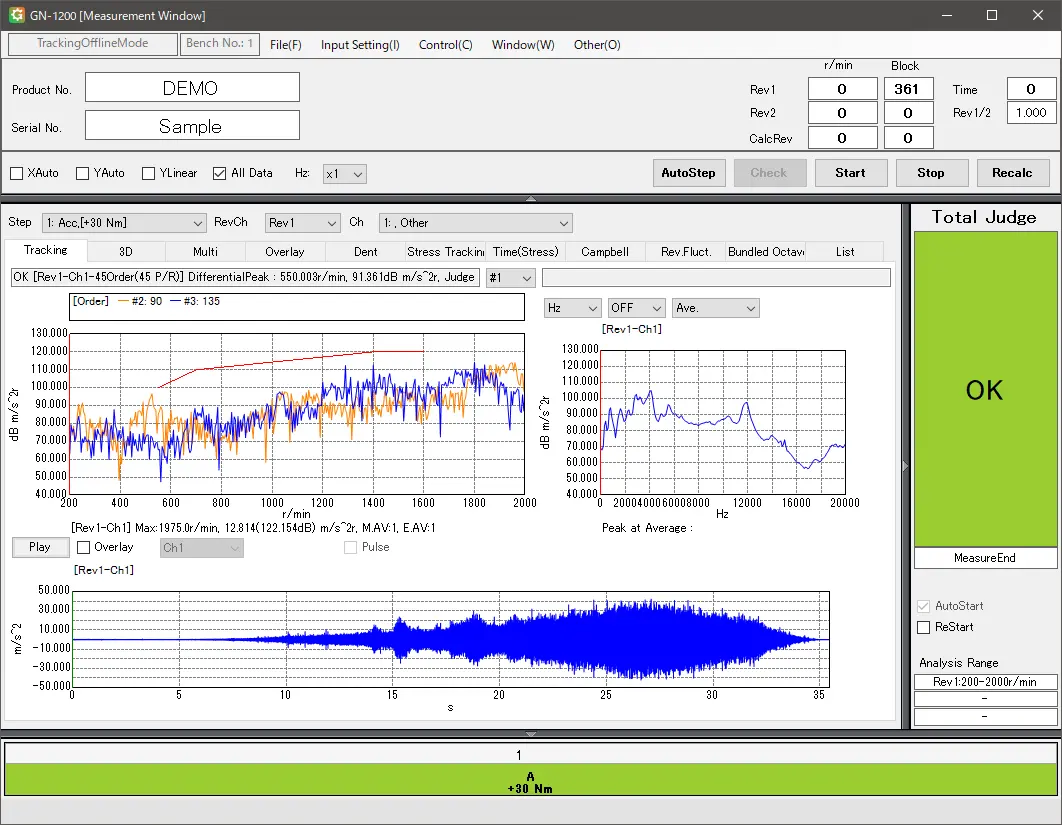

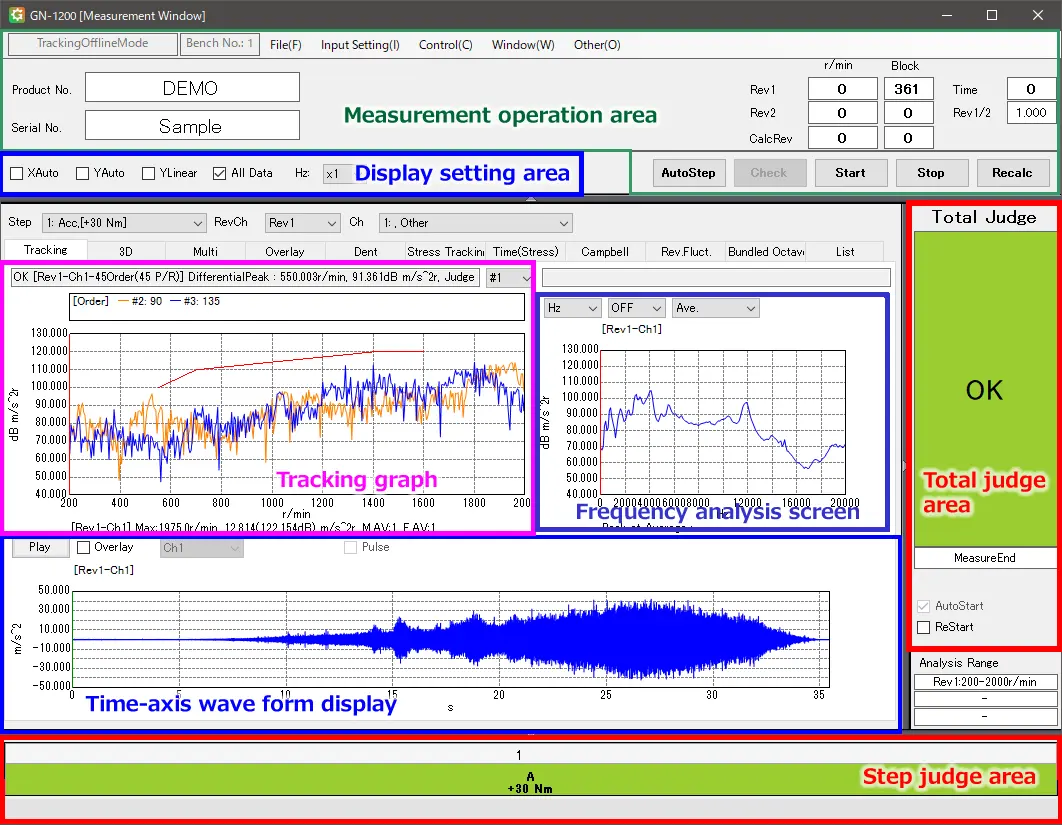

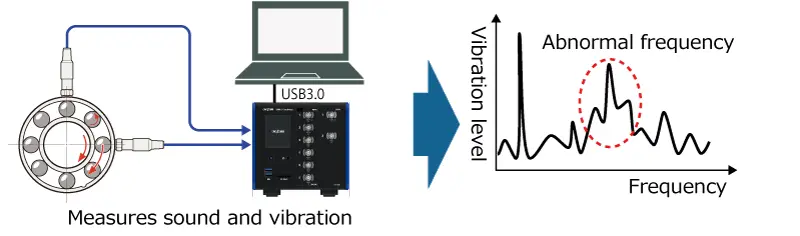

This software has a comparator function for abnormality diagnosis based on sound/vibration analysis.

You can perform simultaneously the tracking analysis and pass/fail judgment for 2 revolution input channels.

It is ideal for vibration analysis of CVT and in-line 100% inspection such as carrier noise analysis of motors.

New Functions

Enhanced performance of base software

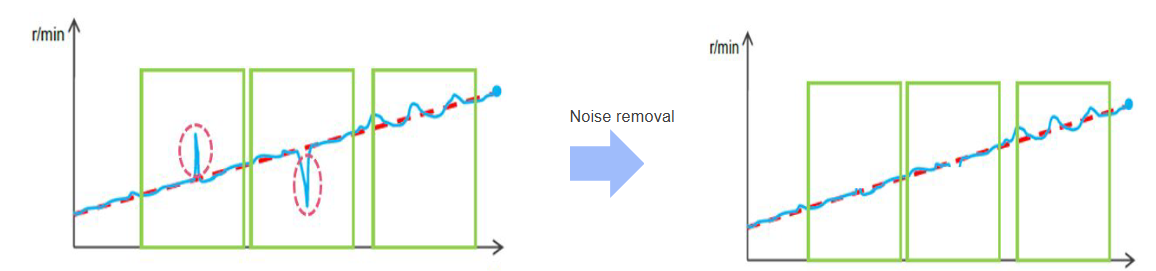

Enhanced abnormal rotation removal function

This function performs appropriate processing so that analysis can be made even when there is momentary noise in the rotation signal.

Added useful functions for options

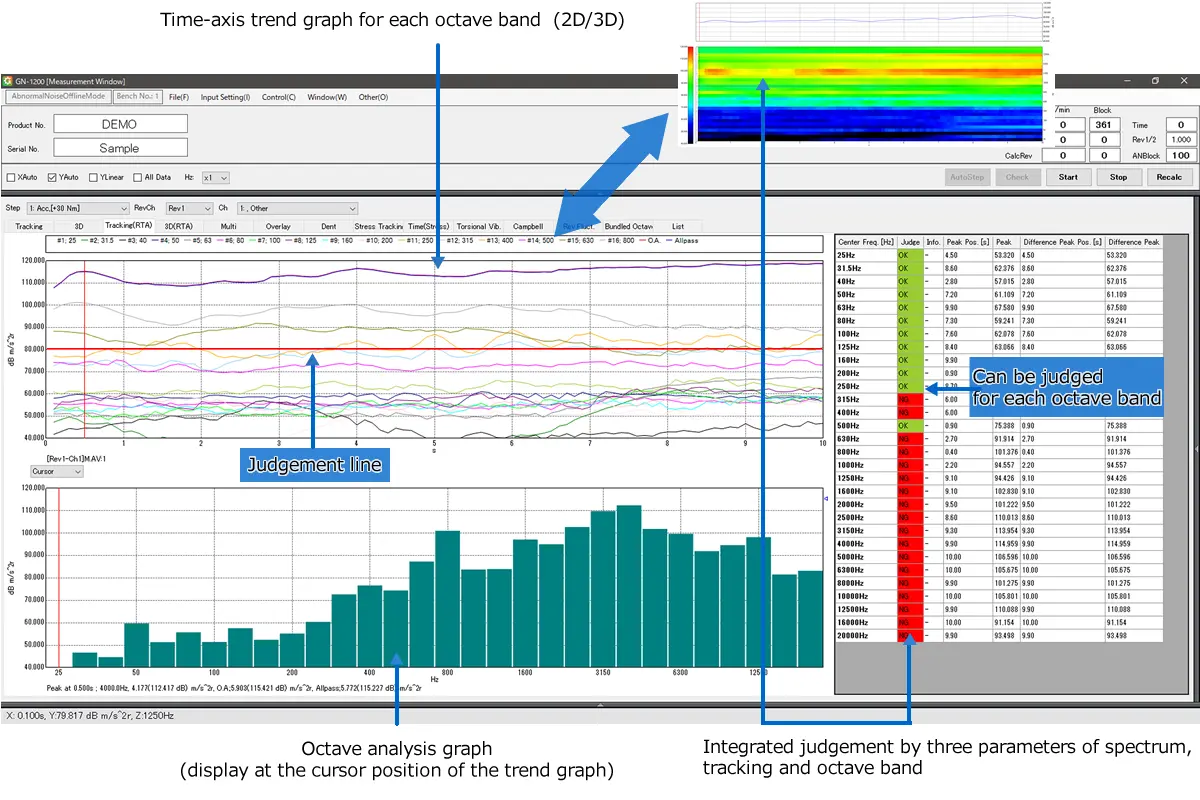

Real-time Octave Analysis Function with Judgment (GN-0170)

When connecting to the DS-5000, the Real-time Octave Analysis with Judgment can be performed.(Ver.4.1 onwards)

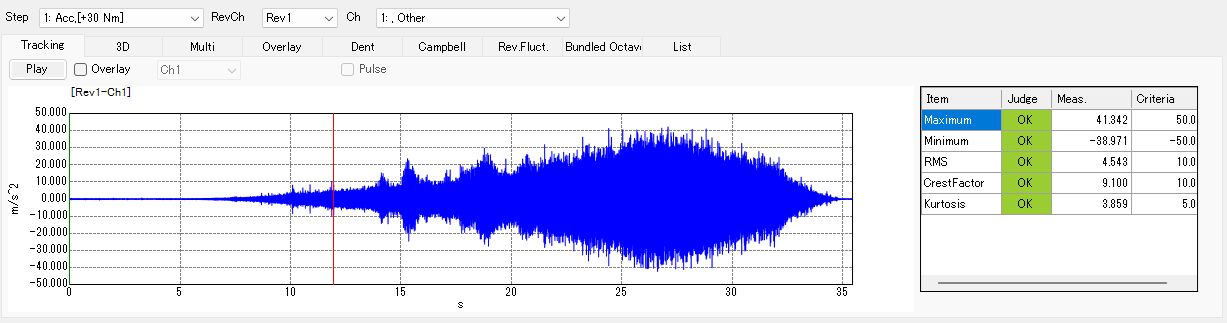

Kurtosis analysis function added (GN-0100)

To take into account the machining accuracy of gear tooth surfaces, a kurtosis analysis function has been added as a general statistically determinable indicator and standardized analytical method.

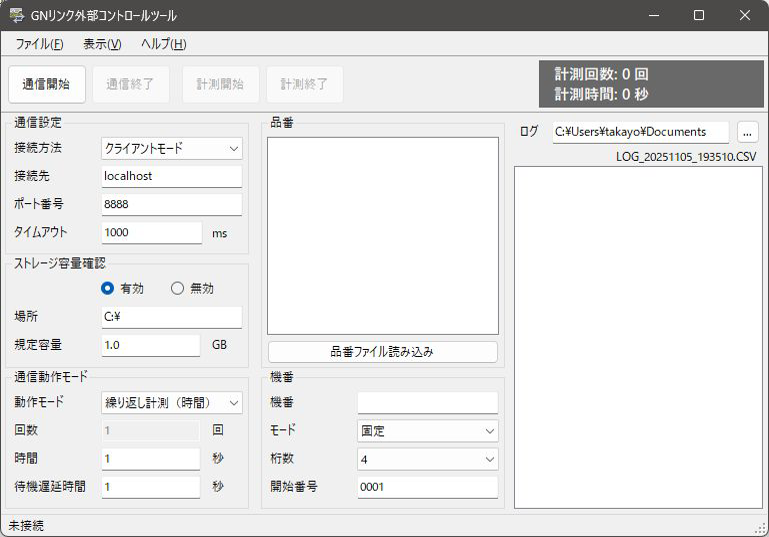

External Control Tool added (GN-0120)

This tool enables automatic measurement without requiring any built‑in modifications to your equipment. Even if you are not skilled at program development, by using this tool you can easily perform simple automated measurements, making it effective for measurements in small-scale situations such as durability tests or during aging processes.

Features

Major windows

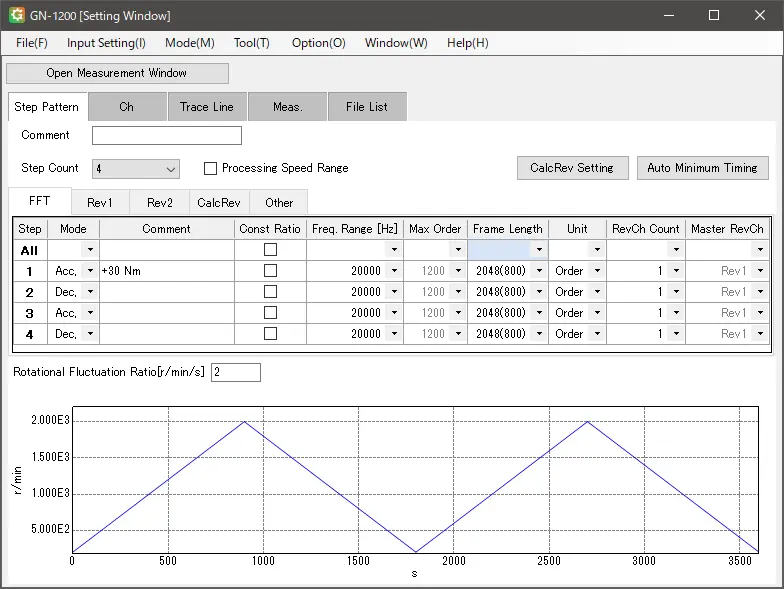

Pattern setting

Up to 20 steps of measurement patterns can be selected by combinations of three items (acceleration/deceleration/constant speed).

Upper/lower-limit rotation speeds and data import interval can be set to each step of each input (Rev1, Rev 2 and calculation revolution).

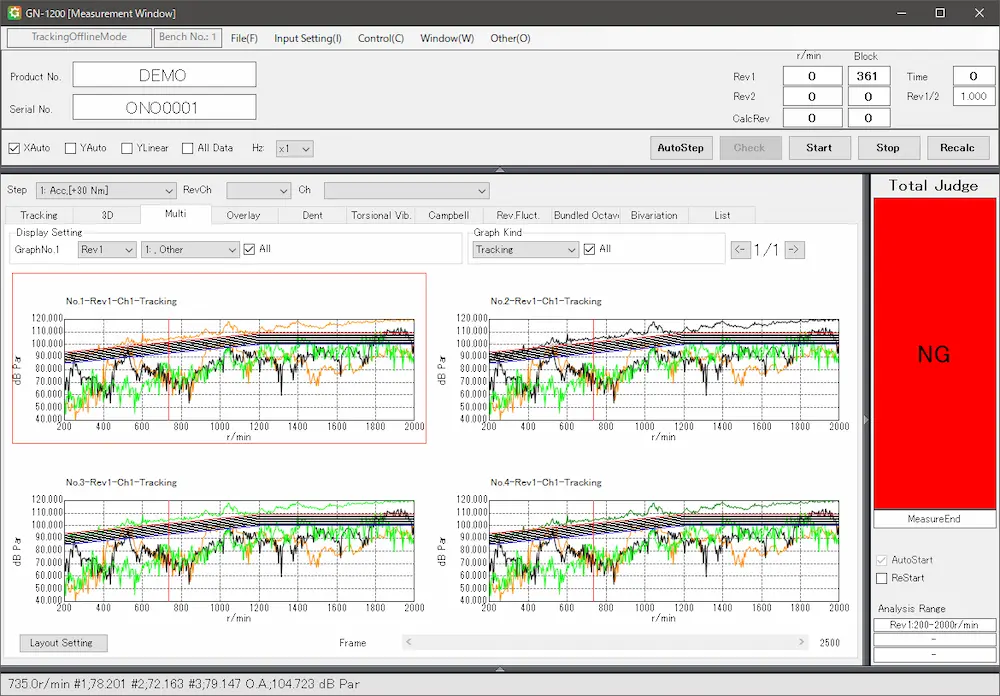

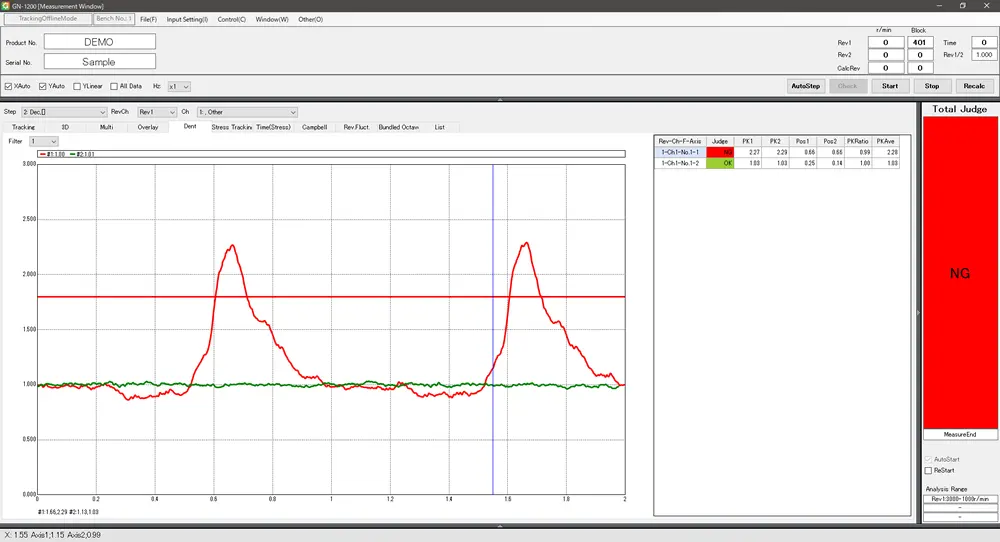

Noise judgment

Judgment, displaying on the screen, and signal output

1. Sections of judge line:up to 32

2. Judge line setting:up to 32

3. Multi judge function

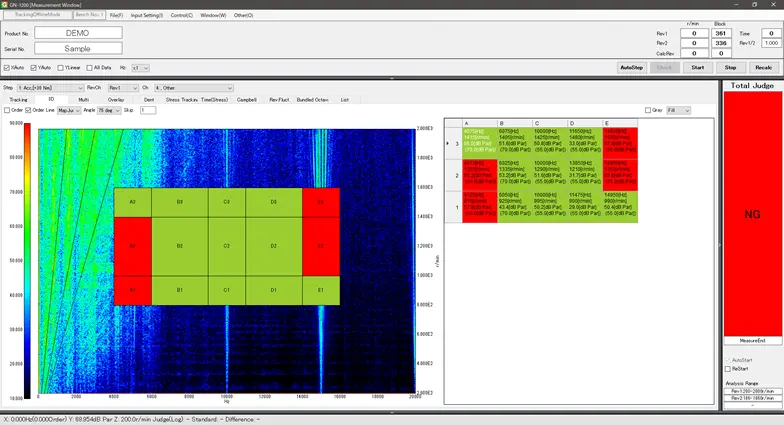

Color Map Judge function

By setting the judgment plane in any band on the color map, make pass/fail judgment of the analysis data. It is effective in detecting high-order noise components caused by waviness and fine processing scratches on the gear tooth surface, abnormalities in motors/inverters, etc.

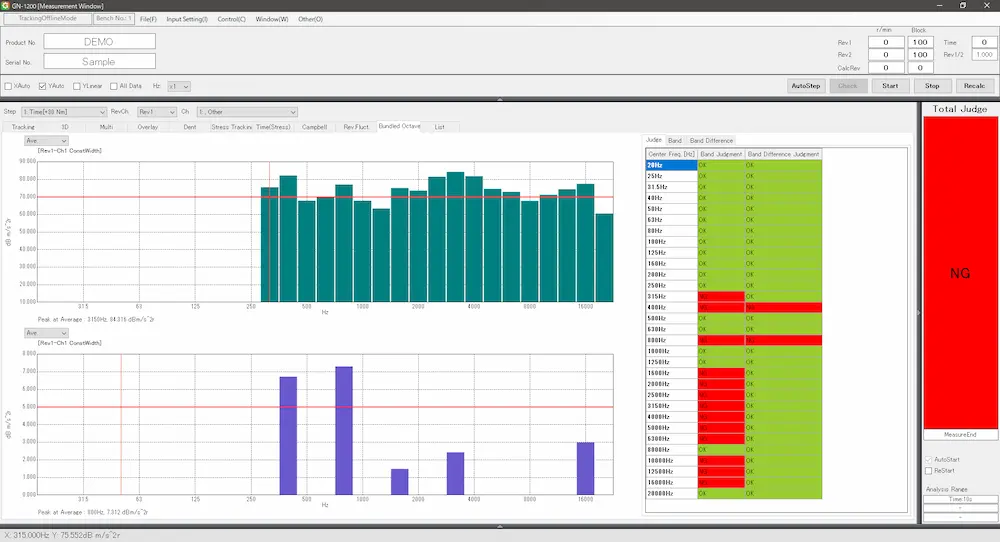

Enhanced octave analysis (1/3 Bundled Octave Judge function)

The judgment function using 1/3 bundled octave analysis that allows you to make pass/fail judgment with a sensation similar to human hearing is added. In particular, judgments using data differences between adjacent bands are effective in extracting harsh or muddy noises.

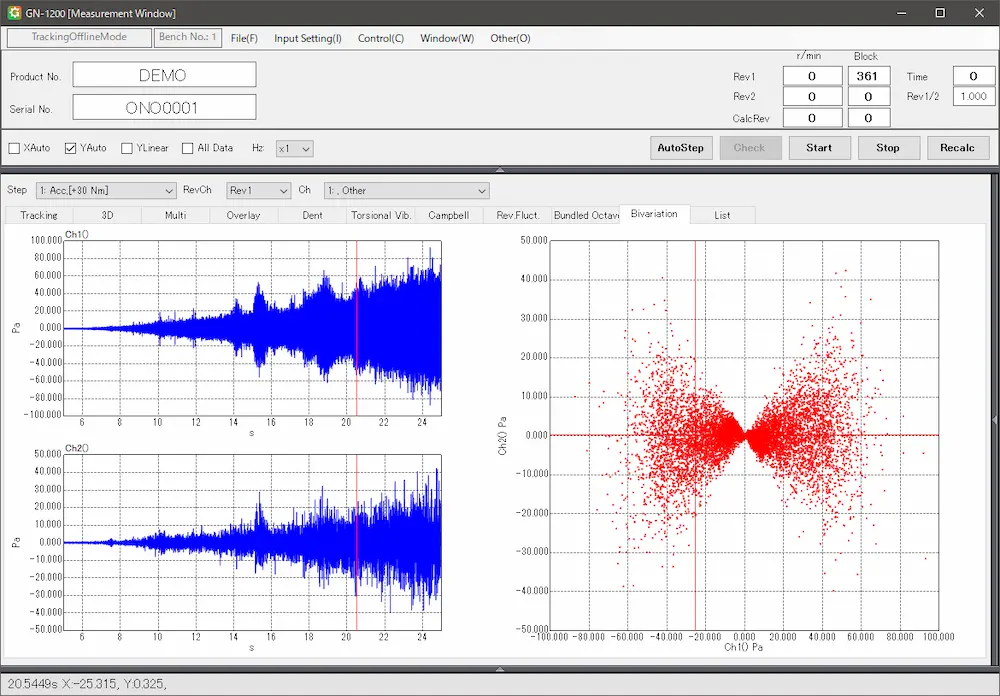

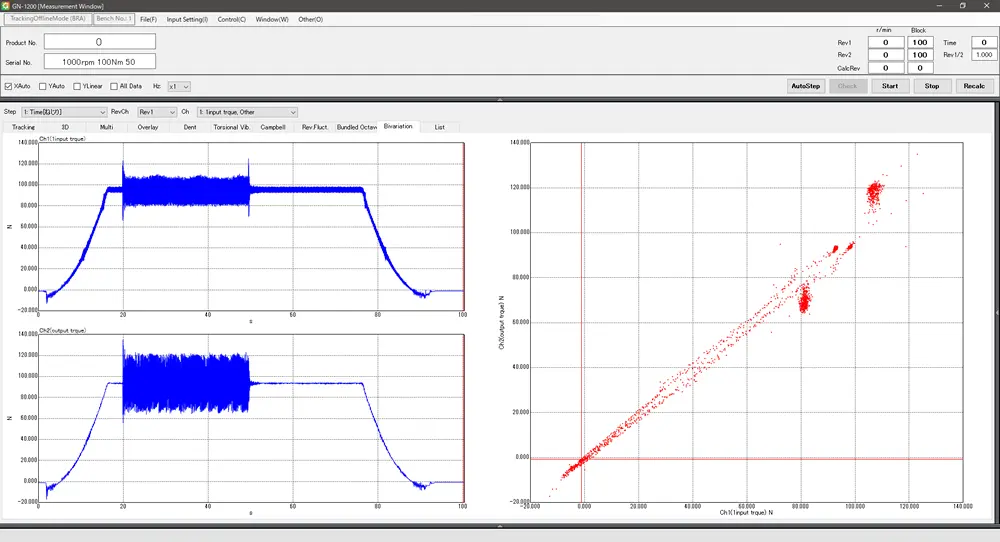

Bivariation Graph Display

By selecting any two data from the data input to the measurement channel/rotation speed channel of the data station, you can display them on a two-axis graph and also perform correlation evaluation. Parameters such as torque, rotational speed, displacement, and vibration acceleration can be used as indexes for run out inspections of motors, etc. during rotating at high speed.

Functions

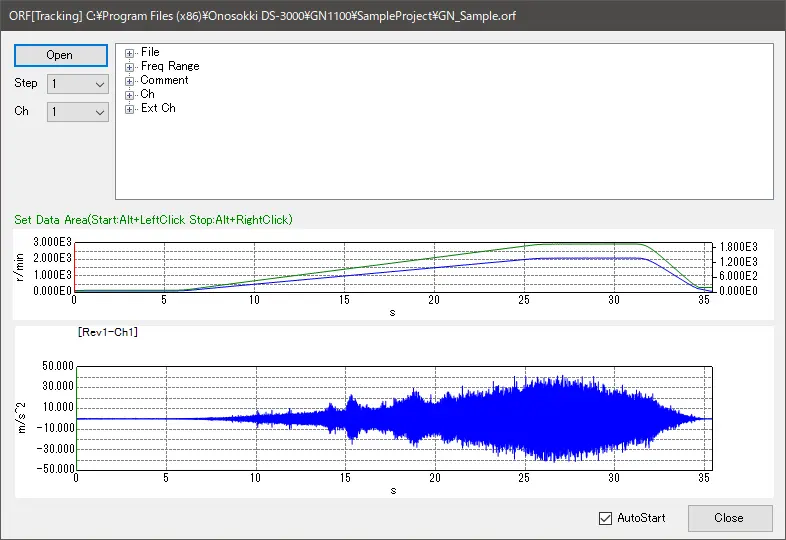

Able to load and recalculate the ORF (ONO SOKKI original format of time-series data) format data.

In addition to the recalculation function, following functions are available.

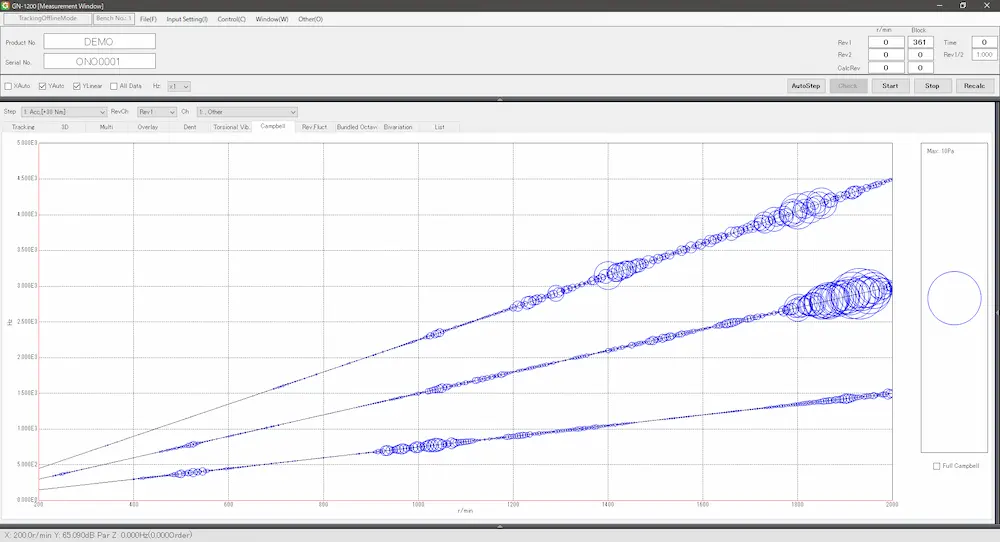

It is effective to improve the measurement by checking resonance and abnormal movement of the work piece.

When the offline tracking mode is connected to the DS-5000/DS-3200 series hardware, re-analysis is possible by changing the analysis condition immediately after measurement using the most recently recorded data.

Also, reanalysis of the ORF file imported to the following load-only screen is possible in the selected analysis condition.

* GN-1200 enables only loading and recalculating the ORF file.

Importing data

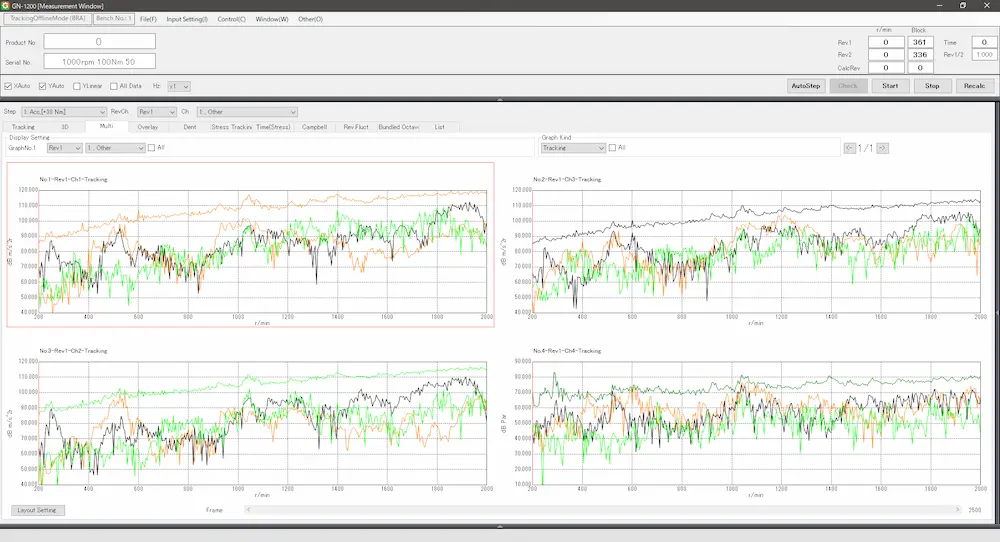

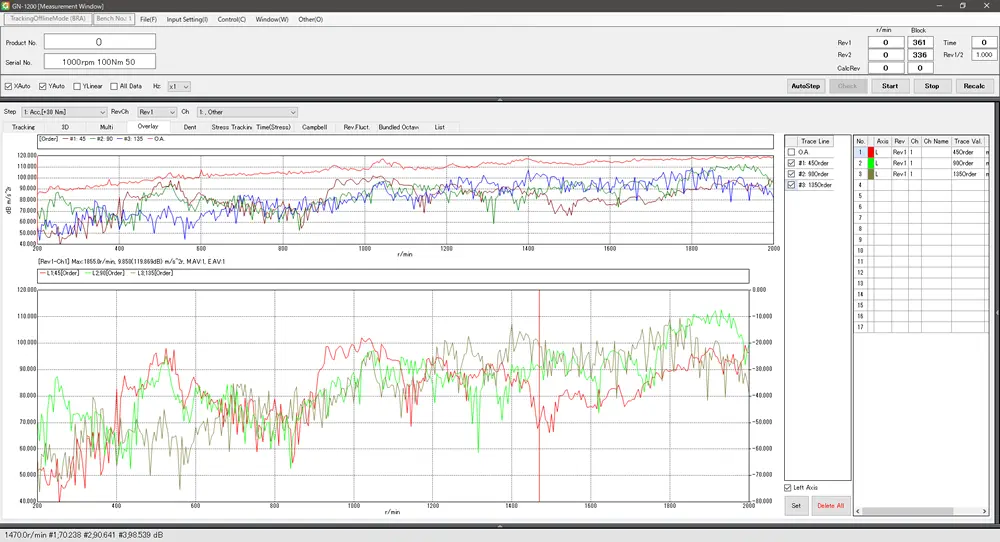

Multiple simultaneous display

Overlay

Campbell diagram

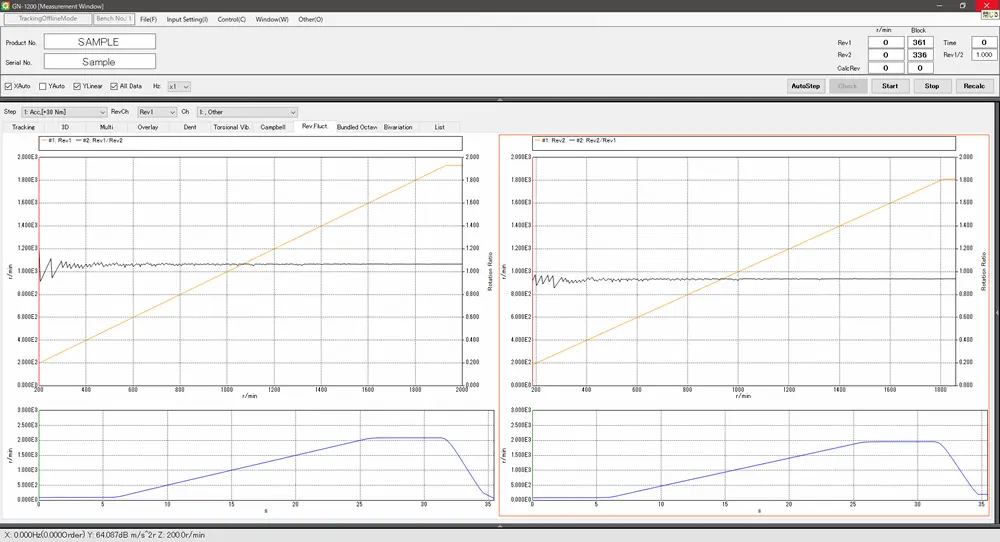

Rotation variation analysis

Bivariation analysis

Judgment by Spectrum P.O.A.

The peak becomes large when a bearing or a gear has damage. The damage can be checked by narrowing to specific frequency bands and making judgments using power addition.

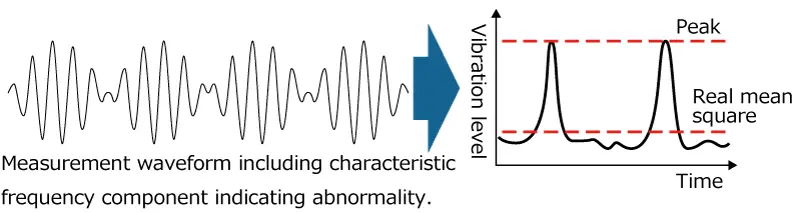

Judgment by Crest factor

Focusing on that the measurement waveform has the characteristic frequency component when damaged, the breakage can be checked by making judgment with peak value/real mean square.

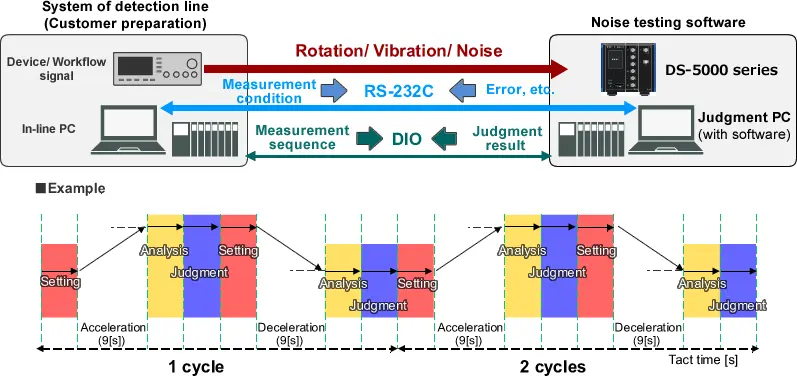

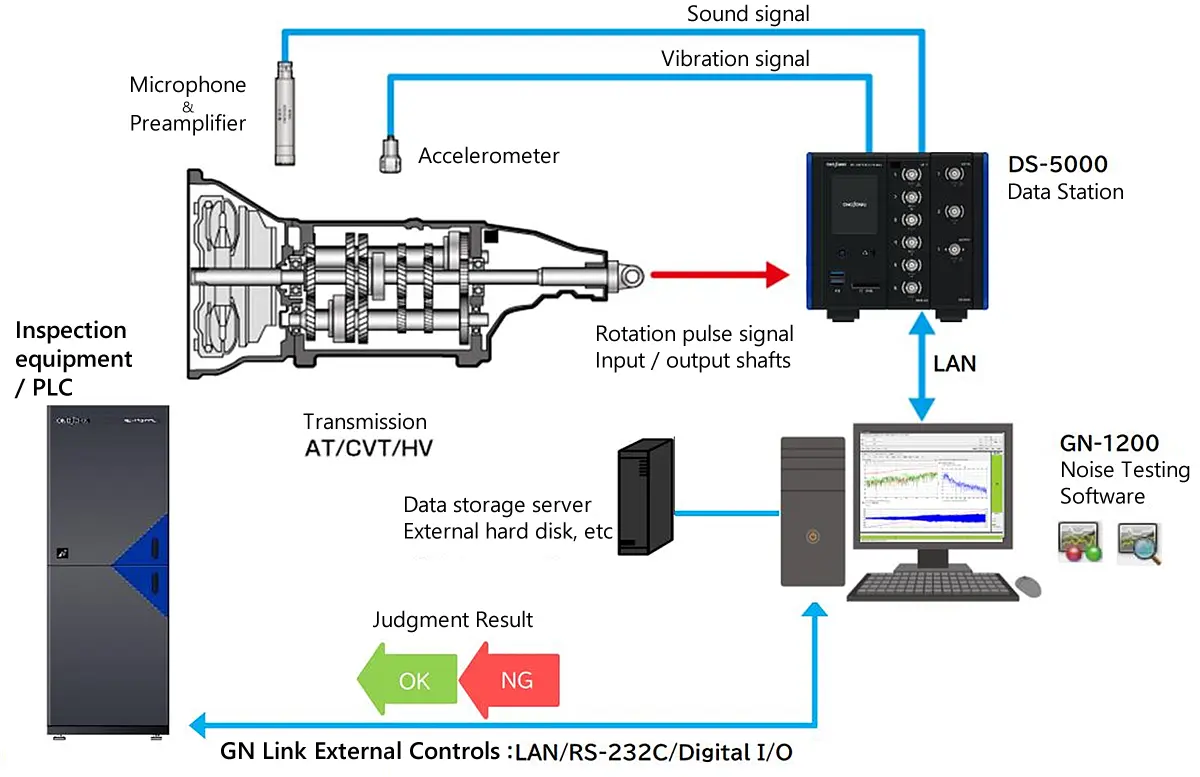

By connecting the GN-1200 to equipment that performs performance tests on work pieces in the production line, it can output the sound/vibration measurement data of work pieces or equipment, as well as work piece pass/fail judgment results, to the equipment. There are three types of communication formats: LAN format (GN-0120)/LAN+DIO format (GN-0240)/RS-232C+DIO format (GN-0240).

* Special order products.

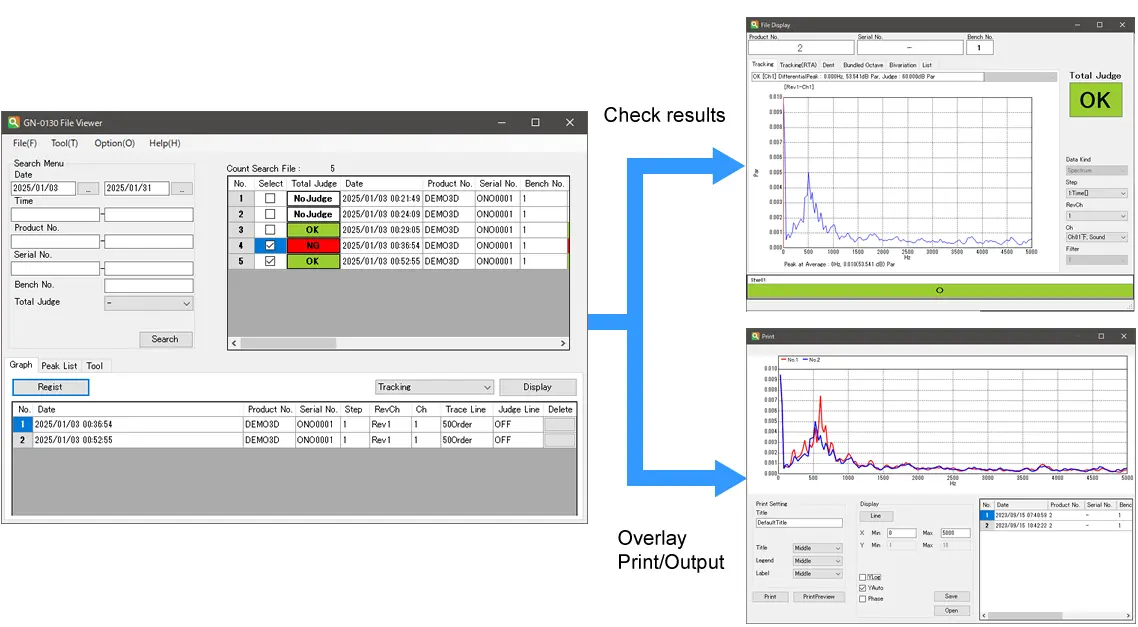

This function is for data management of the large number of files which has been measured and made judgment by the GN-1200. It can be used for searching the workflow information of measured data, and enables to narrow down the multiple workflow data measured in similar condition to perform overlay comparison or averaging.

It is frequently used for checking the entire data.

By checking all data other than the remarkable components, or by displaying two graphs side by side, it becomes easier to compare differences in test conditions or test specimens.

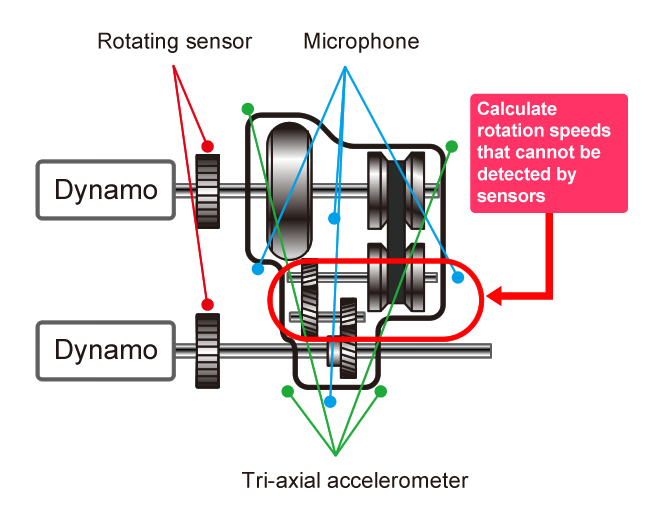

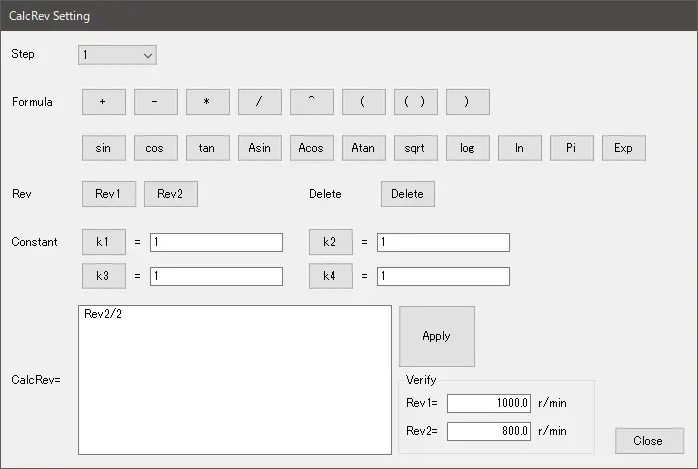

The GN-0140 allows simultaneous tracking analysis and judgment of Revolution Input Ch1 and Ch2. The GN-0150 determines CalcRev for the calculated revolution input from Revolution Input Ch1 and Ch2 by combining 11 types of functions, four arithmetic operations and constants. Up to three channels can be set. By using this function, you can simultaneously perform tracking analysis and verify workpiece behavior in greater detail.

* Calculation revolution is only available for GN-0150.

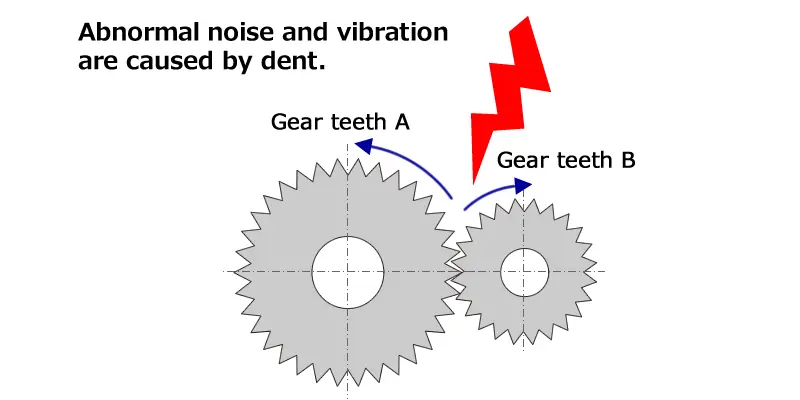

GN-0160 Dent Analysis function

The envelope processing is applied to the time-axis waveforms of the measured vibration and sound pressure, and the magnitude at peak, the phase (period),

the ratio for each period of the waveform are monitored. It is suitable for detecting abnormalities that occur in a specific period and effective for checking the presence of dents on gears and scratches on bearings.

Further, it can be used for the measurement during not only constant rotation speed but also acceleration/deceleration.

GN-0230 Envelope analysis function

This is a function that uses the same method as GN-0160 to judge periodic whining sounds which are caused by shaft vibration or uneven rotation based on the peak value.

1. Dent measurement:Up to 32 pairs

2. Number of rotation axis:Up to 6 axes

3. Reference rotation:Rev1/Rev2

4. Rotation ratio:Rotation speed ratio/gear ratio

* When using the envelope analysis function, the peak value is used for each rotation.

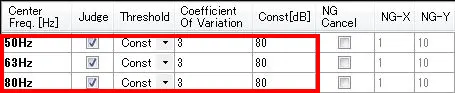

The GN-0170 can make pass/fail judgment of work and equipment by 1/3 octave analysis. This function makes it possible to quantitatively perform "judgment close to the auditory sensation of human" having a characteristic proportional to the frequency component, and supports to build up the human-independent test system.

Also, it can recalculate the optimum threshold using data group judged to be normal in the past, and automatically generate judgment lines.

This function contributes to reduce man-hours in standard management at the time of judgment.

* It will be compatible with the DS-5000 soon.

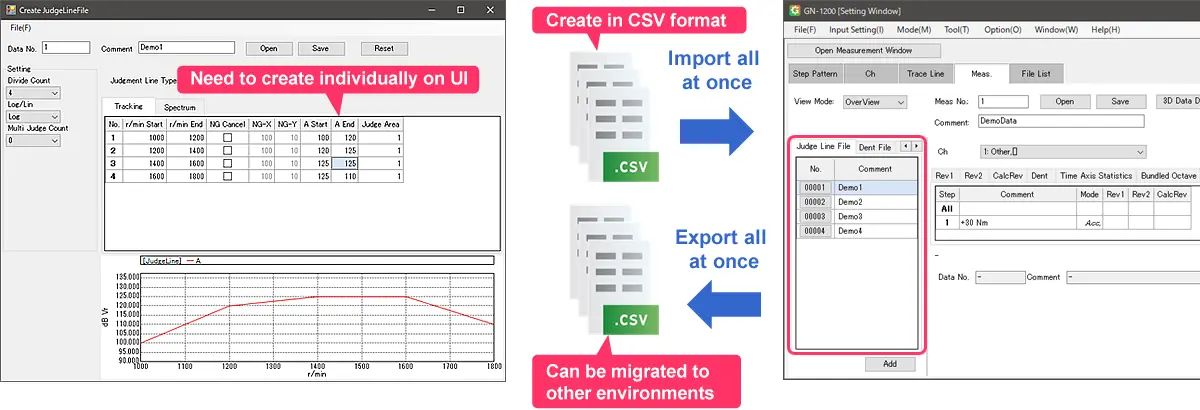

Setting example of judgment line

Statistically processes normality judgment data and automatically generates judgment lines. The value outside the normality range is judged to be abnormal.

* Manual setting is also possible (file import etc.).

Application example

Abnormality inspection of transmission and speed reducer

Abnormality inspection of a motor

Abnormality inspection of an engine

Analysis of low frequency sound

Measurement of equipment noise/ vibration

Measurement of sound pressure characteristics of various acoustic products

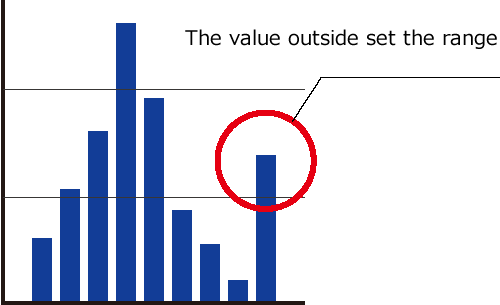

This function allows you to automatically perform analysis by describing operational commands from setting changes through result output. When repeatedly performing recalculations, you can streamline your work and reduce operational errors.

In addition, a new feature has been added that enables automatic post-processing analysis when data files are placed in the specified location. Even when analysis under multiple conditions is required that cannot be handled with a single license, you can efficiently perform continuous post-analysis and abnormality detection.

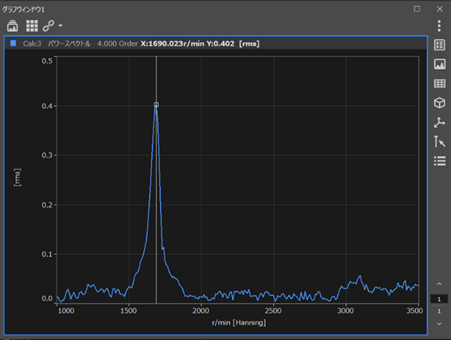

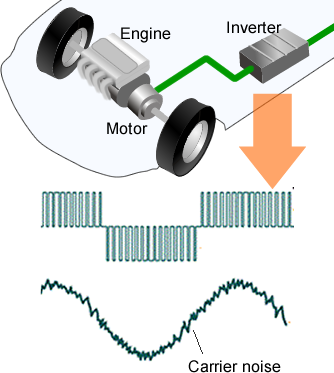

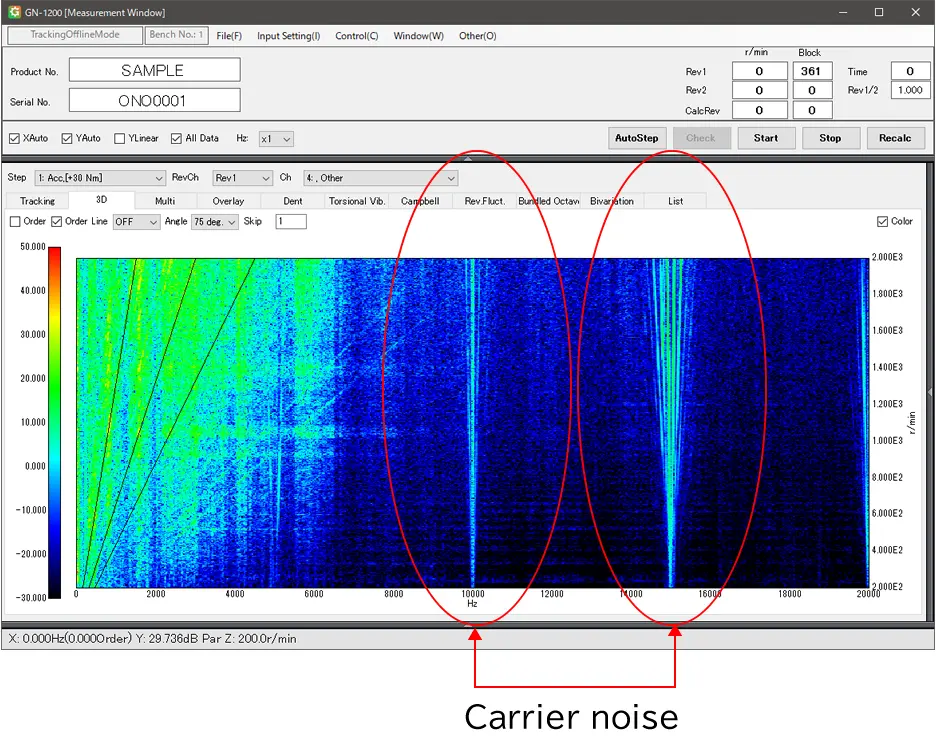

This function allows tracking analysis of the noise caused by the carrier frequency, which is used to change the frequency driving a gear from an inverter in hybrid automobiles, and the order originated from the carrier frequency.

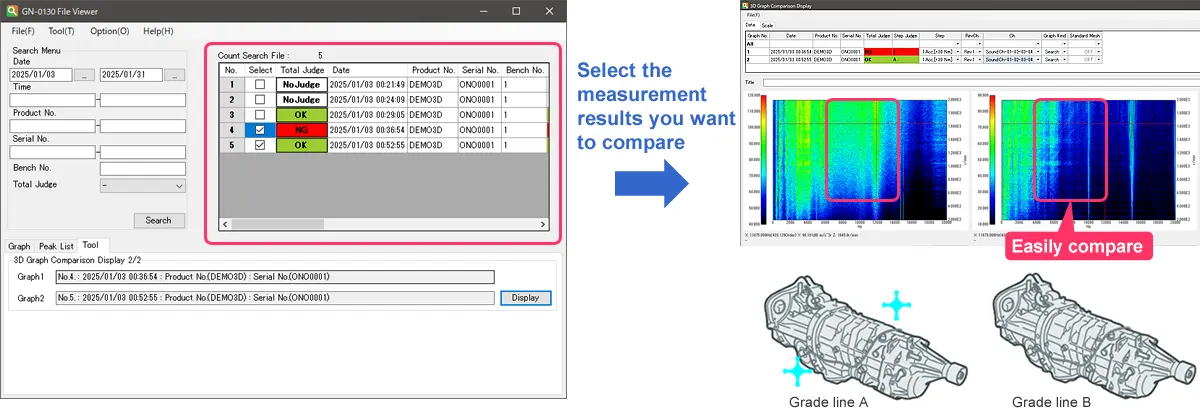

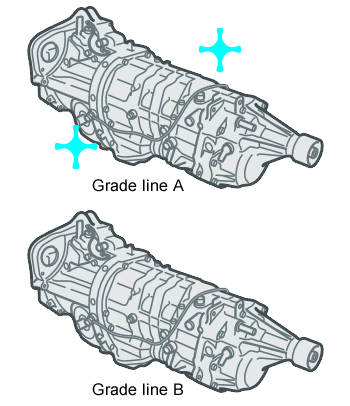

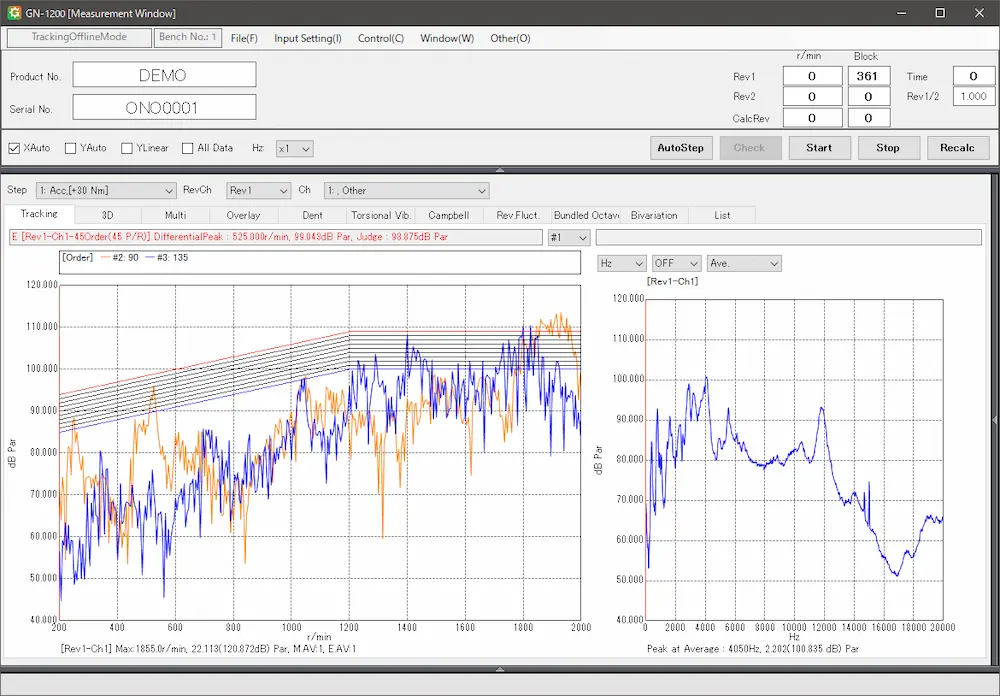

The Grade Line function is for creating grade lines as the base for comparing and assessing the measured peak value in different measurement facilities. Additionally, in order to manage a large amount of measurement data, arbitrary information such as operator/equipment name/measurement details can be added as specifications. This function can be used by factory quality control departments to manage work piece variations and visualize quality change points.

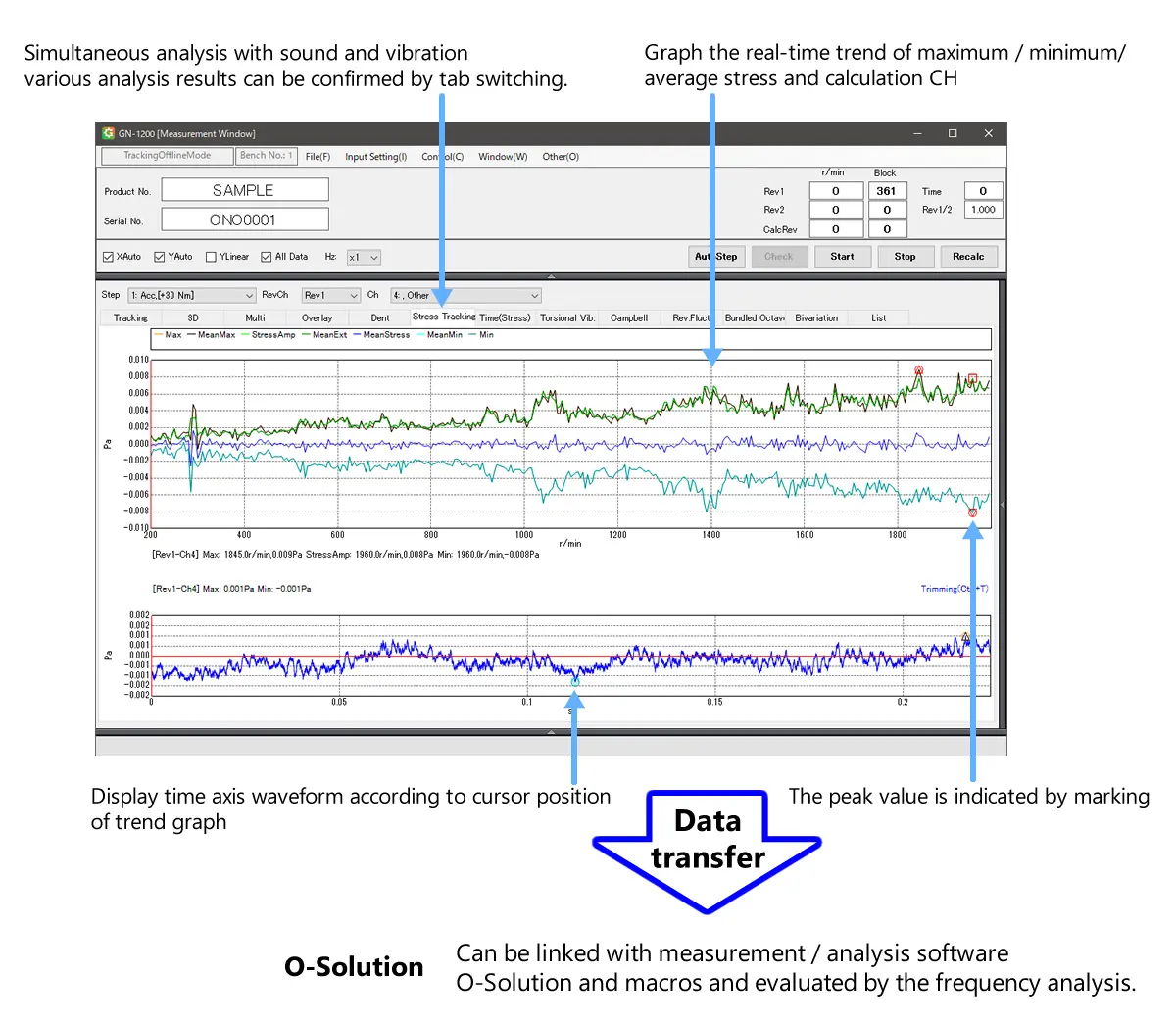

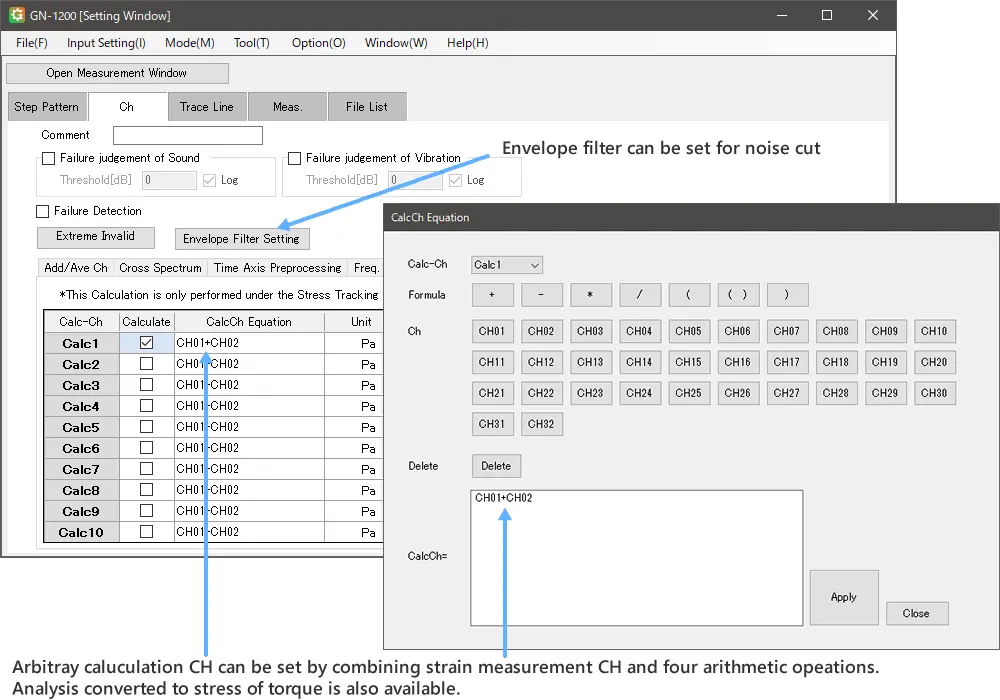

This function analyzes in real time the repeated stress and load behaviors applied when the works are in operation by using detected signal of a strain gauge. Helpful to check the strength and safety.

Application example

Production line quality inspection of unit, such as motor, transmission, and speed reducer.

Abnormality inspection of prototype vehicles and parts incorporated in test equipment.

Strength evaluation of new materials.

And other various scenes

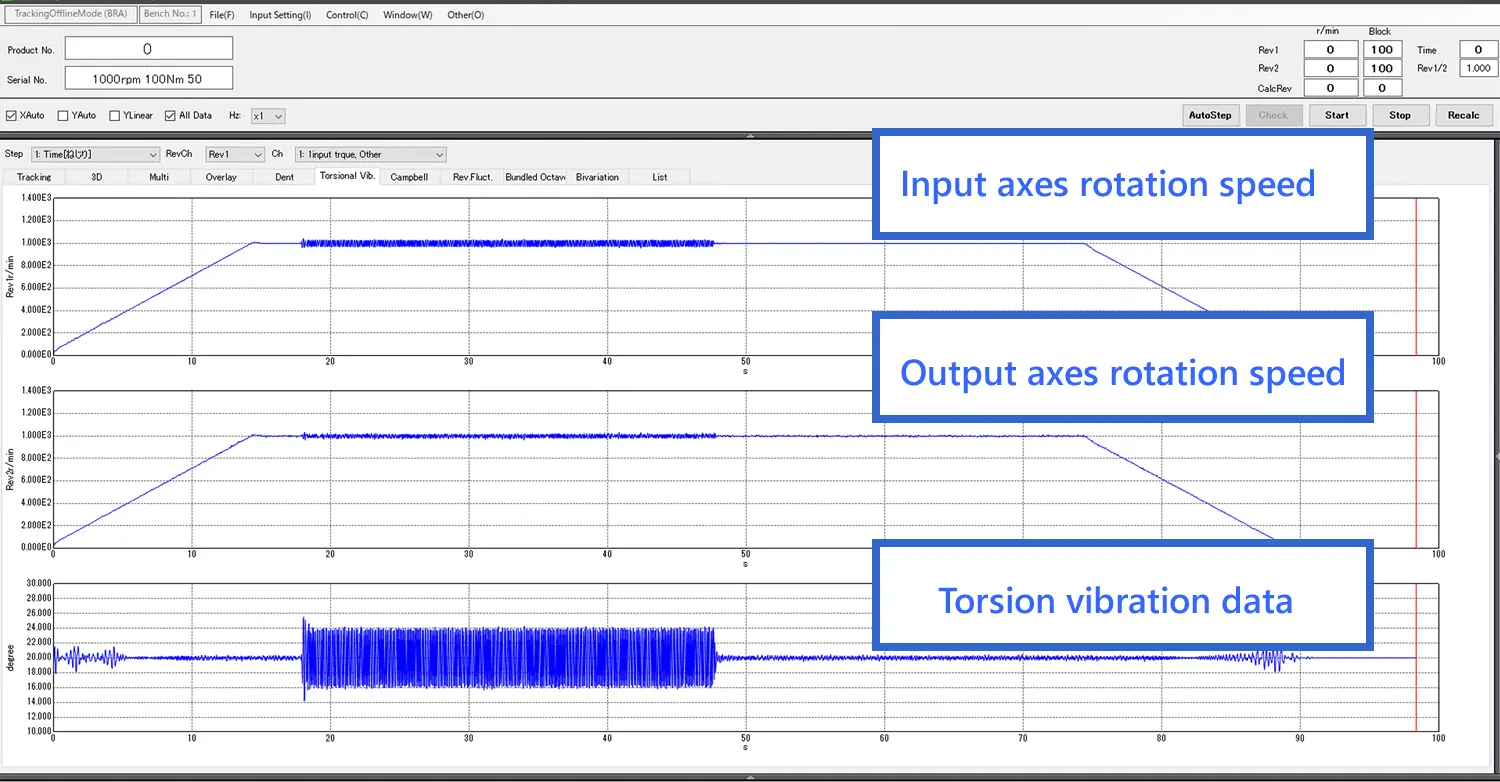

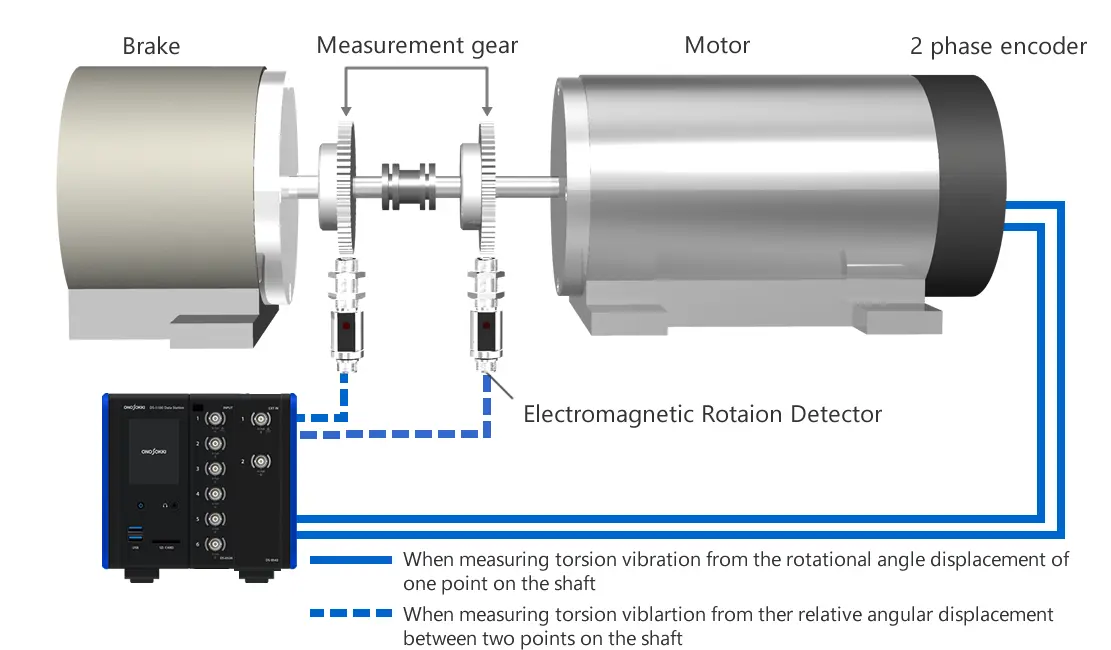

This function calculates the difference in rotation speed between the rotation speed signal from the reference axis

and the compared axis, and outputs the torsional amount of the rotating shaft.

If a high load or high torque is applied to a part or unit in the direction of rotation, it may cause abnormalities such as shaft damage

or abnormal noise. By using this function, it is possible to evaluate the torsional amount and obtain data for verifying the durability

of parts and the presence or absence of abnormalities.

Application examples

Inspection of motor shaft torsion and rotation fluctuations

Torsion inspection of clutches and dampers

Rotation transmission measurement of drive unit, etc.

Example of system configuration

Specifications

| Number of max.ch | Input 42 ch/Revolution 2 ch Input 48 ch/No revolution ch |

|---|---|

| Upper limit sampling frequency | up to 20 ch : 102.4 kHz

up to 40 ch : 64.0 kHz up to 48 ch : 51.2 kHz |

| Number of analysis tracks | 16 tracks+OA |

| Frequency analysis | FFT 6400 lines/bundled of octave |

| Max. analysis order | 1600th order |

| Rev. reference | Revolution1 / Revolution2 /calculation revolution of Rev.1 and Rev.2 |

| Average | Exponential average/moving average |

| Composite calculation | Sound : max.1ch, Vibration : max.10ch |

| Front end | DS-5000 series / DS-3200 series |

|---|---|

| OS | Microsoft Windows® 10 Pro (64bit), Microsoft Windows® 11 Pro (64bit) Microsoft Windows® 10 IoT enterprise 2019 LTSC, Microsoft Windows® 10 IoT enterprise 2021 LTSC Please refer to the software operating environment [Windows] for the details of the version. Microsoft .NET Framework 4.8 or later |

| CPU | Intel Core TM i7 8th generation or later, Base clock frequency 3.0 GHz or higher recommended |

| Memory | 16 GB or more |

| Display | 800 X 600 or more |

| Interface | LAN x 1 port or more (for DS-5000 connection), USB Type-A x 1 port or more (for USB key) *When using the GN link function, the following ports are required. TCP/IP: LAN port, RS-232C: Serial port, Digital I/O: PCI port |

| Optical drive | CD/DVD drive |

Software & Option

| Model name | Product name | Overview |

|---|---|---|

| GN-1200 | Noise Testing Software | Main application, tracking analysis and judgment for the Revolution Input Ch1, 1/3 bundled octave analysis and judgment, list display |

| GN-0100 | ORF Input & Recalculation Function | Reading ORF file, recalculation |

| GN-0110 | Secondary Data Processing Function | Reading ORF file, recalculation, time axis statistics |

| GN-0120 | GN Link Function (LAN) | External communication function using LAN (TCP/IP) |

| GN-0240 | GN Link System (LAN+DIO or RS+DIO) | External communication function using LAN(TCP/IP)+DIO or RS-232C+DIO |

| GN-0130 | File Viewer Function | Search for data file, overlay, peak list display |

| GN-0140 | Dual Rev Tracking Function | Simultaneous processing of tracking analysis and pass-fail judgment of 2 rotation inputs. |

| GN-0150 | Calculation Rev Tracking Function | Simultaneous processing of tracking analysis and pass-fail judgment of three rotation inputs. (including GN-0140) |

| GN-0160 | Dent Analysis Function | Dent judgment during tracking measurement of acceleration/deceleration |

| GN-0170 | Real-time Octave Analysis Function

|

Pass/fail judgment by 1/3 octave analysis |

| GN-0180 | Auto Sequence Function | Auto analysis function using command files (including GN-0100) |

| GN-0190 | Offset Tracking Function | Tracking analysis of the high frequency noise caused by inverter carrier signal. |

| GN-0200 | Grade Line Function | Creating grade lines, setting of specification information, search function, output of peak data |

| GN-0210 | Stress Tracking Analysis Function | Tracking analysis of strain gauge signals and inter-channel calculation signals set by arbitrary four arithmetic calculations |

| GN-0220 | Torsion vibration operation function | Calculating the torsional amount from the differences between two rotation speed signals (including GN-0140) |

| GN-0230 | Envelop Analysis Function | Abnormality detection judgment using envelope processing |

*

Windows®7 、Windows®10 are registered trademarks of Microsoft Corporation in the United States and other countries.

*

Intel, Intel logo, Intel Core, Core Inside are trademarks of Intel Corporation in the United States and other countries.

Related Information

Last update: 2026/1/30