Diesel Engine Tachometer

GE-2500

The GE-2500 diesel engine tachometer uses rotation speed of an alternator to measure engine rotation speed. With FFT calculation, this tachometer achieves reliable and stable measurement for both diesel and gasoline engines.

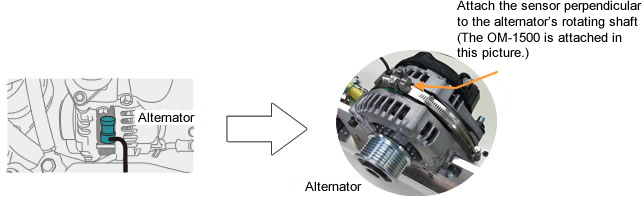

The OM-1500 is a compact type detector designed for measuring rotation speed of an alternator. It detects magnetic flux leakage from an alternator. It is used to combine with the GE-2500. (The OM-1200 can also be used with the GE-2500.)

(*It may not be measured or may be changed the measurement range depending on the engine and motor type. For more details, please contact your nearest distributor or send us an e-mail, overseas@ONO SOKKI.co.jp) |

Features

-

Rotation of both gasoline and diesel engines can be measured.

-

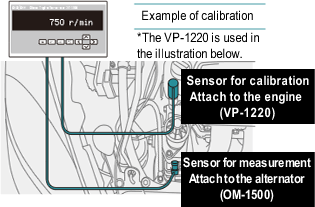

Auto calibration function is provided. The rotation speed ratio of the alternator and engine is calibrated automatically.

-

Easy setup.

The sensor can be set any place of an alternator. -

Enables small signal detection by FFT calculation

By using rotation speed of an alternator, the rotation speed of the engine can be measured regardless of engine types and number of cylinders.

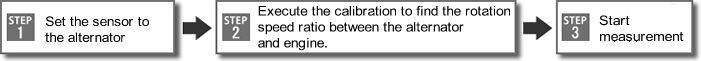

The rotation speed ratio between the alternator and engine is required to calculate the engine rotation speed. Calibration must be executed before measurement to find the rotation speed ratio.

Possible to measure while driving

High noise tolerance and stable measurement

The GE-2500 can find solutions for engine rotation measurement

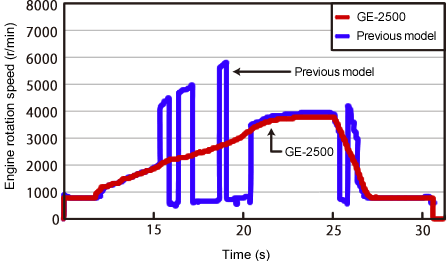

Comparison of the GE-2500 and the previous model (6-cylinder engine)

The GE-2500 enables stable measurement in entire range even when the engine rotation speed is increased.

Measurement method

|

|||||||||||||||||||||||||||||||||||||

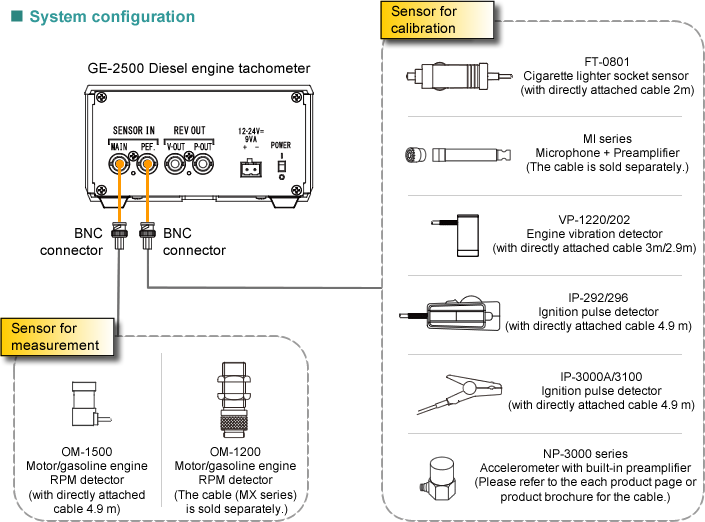

System configuration and connection example

Overview specification

| Measurement section | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measurement object | Diesel engine, gasoline engine with an alternator | ||||||||||||||

| Calculation method | FFT calculation | ||||||||||||||

| Input frequency range | 1 kHz, 2 kHz, 5 kHz (Measurement mode: MAIN) / 500 Hz(Calibration mode: REF) | ||||||||||||||

| Measurement accuracy | ±2 × rotation speed resolution (r/min)± 1 count | ||||||||||||||

| Rotation speed resolution | Frequency range(Hz) ÷ 12800 × 60 ÷ rotation ratio | ||||||||||||||

| Display section | |||||||||||||||

| Display | Fluorescent display tube | ||||||||||||||

| Display update cycle | Selectable from 0.2, 0.5, 1 or 2 (second) | ||||||||||||||

| Display resolution | 1 r/min, 1 Hz | ||||||||||||||

| Measurement display range | 20,000 r/min | ||||||||||||||

| Input section | |||||||||||||||

| Input section | 2-ch MAIN(for measurement) REF(for calibration) | ||||||||||||||

| Input voltage range | ±5 V, ±0.5 V, ±0.05 V | ||||||||||||||

| Input connector | BNC | ||||||||||||||

| Input coupling | AC coupling | ||||||||||||||

| Constant drive power supply | 2.2 to 3.2 mA(REF only) | ||||||||||||||

| Analog output section | |||||||||||||||

| 【 REVO 】 |

|

||||||||||||||

| 【 SIG 】 |

|

||||||||||||||

| Pulse output section | |||||||||||||||

| Output information | Outputs frequency of display rotation speed. [when at 6,000 r/min, 100 Hz Duty1:1] |

||||||||||||||

| Output voltage | Lo:0.5 V or less, Hi:4.5 V or more(at no load) | ||||||||||||||

| Output update cycle | 200 ms or less | ||||||||||||||

| Load resistance | 100 kΩ or more | ||||||||||||||

| Output connector | BNC | ||||||||||||||

| General specification | |||||||||||||||

| Power supply | DC 12 to 24 V | ||||||||||||||

| Power consumption | 8 VA or less | ||||||||||||||

| Operating temperature range | 0 to +40 °C | ||||||||||||||

| Operating humidity range | +20 to +80 %RH (with no condensation) | ||||||||||||||

| Storage temperature range | -10 to +55 °C | ||||||||||||||

| Storage humidity range | +20 to +80 %RH (with no condensation) | ||||||||||||||

| Outer dimensions | Approx. 144(D)× 72(H)× 180(D)mm (not including protruded section) |

||||||||||||||

| Weight | 2 kg or less | ||||||||||||||

| Standard | CE marking, RoHs | ||||||||||||||

| Accessories | Instruction manual x 3 kinds, rubber support pad x 4, GE-0102 power cable for cigarette lighter plug (1.5 m) x 1 | ||||||||||||||

| Option | GE-0102 power cable for

cigarette lighter plug (1.5 m) (The GE-0102 is supplied as standard accessory of the GE-2500.) |

||||||||||||||

It may not be measured depending on the engine and motor type. For more details, please contact your nearest distributor or send us an e-mail: overseas@ONO SOKKI.co.jp)

To use the GE-2500, the alternator and engine must be running in synch with each other. The measurement error may become large when the special kind of alternator is used or the belt between the alternator and engine is loose.

It can not be measured or a measurement error may become large depending on the structure of an alternator.

Related products

| • Sensor for measurement:OM-1500 or OM-1200 (Detector for rotation speed of an alternator) ···The sensor used when detecting magnetic flux leakage from the alternator. | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor/gasoline engine RPM detector OM-1200 *The cable is sold separately. | Motor/ engine RPM detector OM-1500 |

| ||||||||||||||||||

| • Sensor for calibration:Engine rotation detectors, accelerometers, microphones etc. ···The sensor used when calculating rotation ratio between an alternator and an engine. | |||

|---|---|---|---|

| Ignition pulse detector IP-3100 | |||

Engine revolution detector

(High-sensitive type) | Piezoelectric-type

accelerometer NP-2000/NP-3000 Series | Microphone + preamplifier MI Series | Cigarette light socket sensor FT-0801 |

|

|

Input voltage:12 V, 24 V | |

Related information

Revised:2013/01/07