Laser Doppler Surface Velocity Meter

LV-7000 series

Capable of detecting 2 channels and calculating difference with one main unit

Detecting speed difference with high response and high accuracy using eye-safe laser

The LV-7000 series detects speed, uneven speed, distance, length of moving object or rotating object without contact. By contacting with 2 sensors, it enables to calculate difference in velocity/length between the two points in real time and output with 3,000 ppm of accuracy. The frequency response can be expanded up to 20 kHz, which achieves to understand phenomena and evaluate mechanical systems at high speed, efficiently, and accurately. It is useful for evaluation of motor control and behavior measurement, improving parts quality, and reducing loss of material.

Features

Application

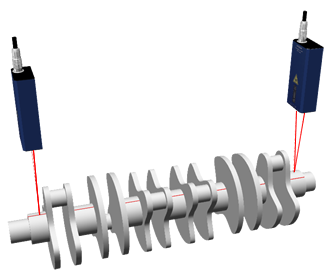

Torsion/torsion vibration measurement

Torsion or torsion vibration measurement of transmission power train, drive-train, rotation shaft, turbine, forging crank and shaft.

Speed and behavior measurement of tire

Behavior measurement between tire and grounding surface, such as speed difference, peripheral speed change/difference, torsion, deformation, slip.

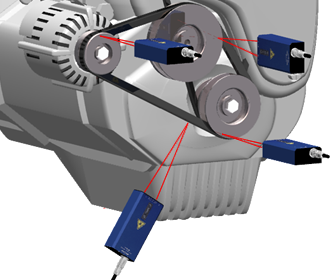

Behavior measurement of pulley/belt

Speed, slippage, expand or contract, and differential of belts for crank pulley, alternator, compressor, compression machine etc.

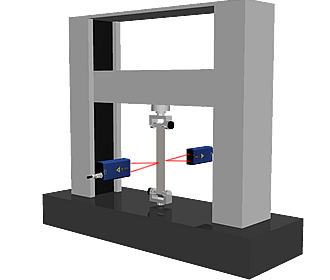

Measurement for material evaluation

Detection of stretching position of material, difference of stretching position and stretching speed, behavior of compression/stretching.

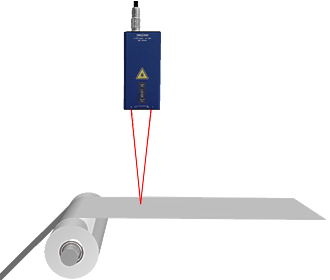

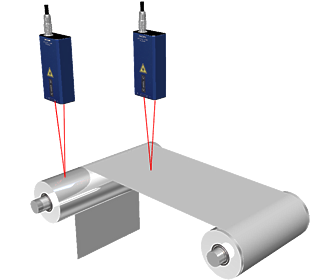

Speed/uneven speed measurement

Speed/uneven speed measurement of paper, film, rubber, woven fabric, non-woven fabric, and plastic

Measurement of winding length

Length measurement of thread, wire for communication facility, copper wire for elevator, hose, harness and coated wire material

Conveyance slip amount measurement

Slip amount measurement on conveyance of printer, photo copy machine, scanner, paper, woven fabric, non-woven fabric and plastic

Conveyance at vertical/negative gradient

Speed·uneven speed measurement of paper, film, rubber, woven fabric, non-woven fabric, plastic on vertical/negative gradient conveyance

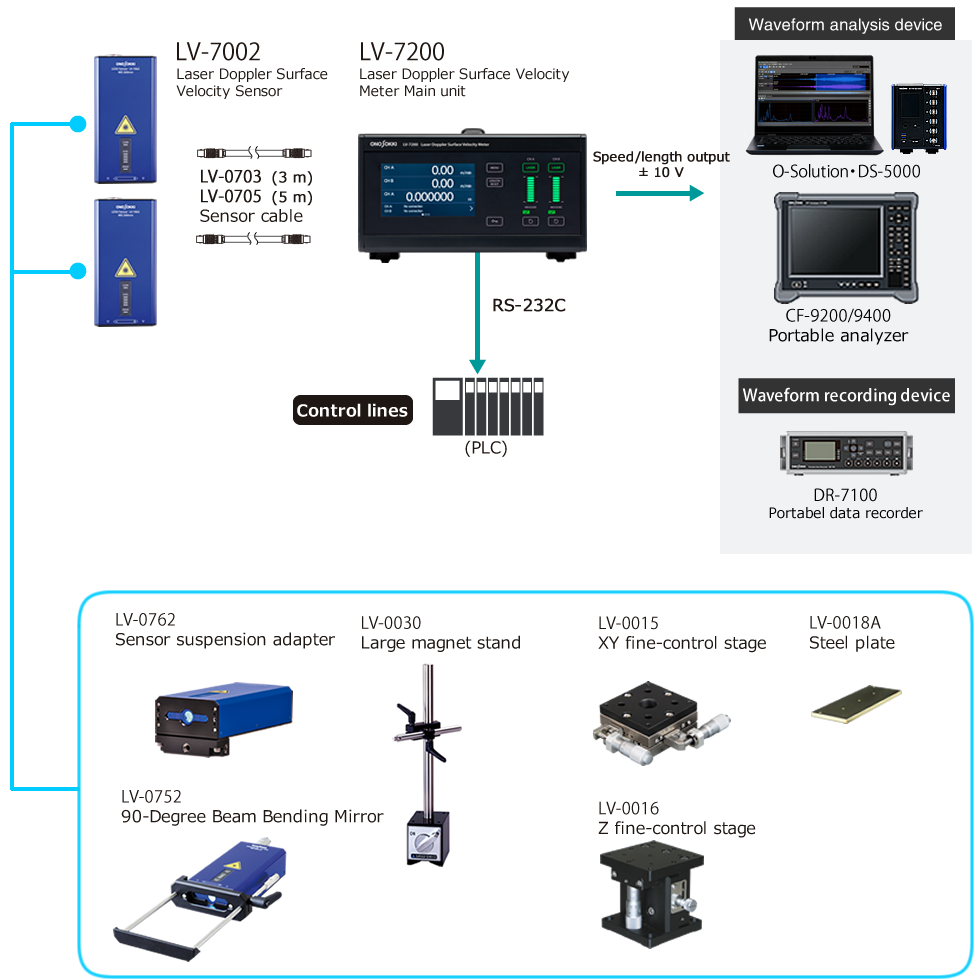

System configuration

Specifications

LV-7002 Laser Doppler Surface Velocity Sensor

| Detection method | Back-scattering differential type | |

|---|---|---|

| Detection direction | "+" when moving from the left to the right in front of the sensor | |

| Distance accuracy | Within ±0.2 % (Length evaluation by our standard plane at 25 °C) | |

| Laser beam | ||

| Laser safety class | Class2 | |

| Measuring laser beam | λ=1550 nm Less than 10 mW, CW oscillation |

|

| Guide laser beam | λ= 635 nm Less than 1 mW, CW oscillation |

|

| Laser spot diameter | 2 mm x 1 mm, ellipse | |

| Detection distance | ||

| Detection distance (center) | 200 mm *from the bottom surface of the sensor | |

| Detection range (depth) | ±4 mm: within ±0.2 % (of reading) ±10 mm: within ±0.5 % (of reading) (Length evaluation by our standard plane at 25 °C) |

|

| Sensor in general | ||

| Scale factor | Approx. 7.5 µm | Reflected automatically at power-on. |

| Detection velocity range | 0 to ±1800 m/min | |

| Maximum tracking acceleration | 800 m/s2 | |

| Light receiving sensitivity monitor | ||

| Light receiving signal level (SIG LEVEL) | Display the level in 5-segment LED (green) | |

| Light signal error (ERROR) | LED (red) lights up when demodulation error is occured. | |

| Outer dimensions | W 75 mm X H 40 mm X D 155 mm | |

| Weight of the main unit | Approx. 750 g (not including option/ cable) | |

| Conforming standard | ||

| Laser safty | IEC 60825-1:2007:2014 | |

| EN 60825-1:2007:2014/A11:2021 | ||

| FDA (CDRH) 21CFR 1040.10 and 1040.11 except for conformance with IEC 60825-1 Ed.3., as described in Laser Notice No. 56 | ||

| CE marking | Low voltage Directive: 2014/35/EU EN 61010-1, EN 60825-1 | |

| EMC Directive: 2014/30/EU EN 61326-1 | ||

| RoHS Directive: 2011/65/EU EN IEC 63000 | ||

LV-7210/LV-7220 Laser Doppler Surface Velocity Meter Main Unit

| Model | LV-7210 | LV-7220 | ||

|---|---|---|---|---|

| Number of Sensor Inputs | 1 (CH A) | 2 (CH A and CH B) | ||

| Detection in General | Polarity | Moving from the left of the front of the sensor to the right: + Moving from the right of the front of the sensor to the left: - |

||

| Detection velocity range | 0 to ±1800 m/min | |||

| 0 to ±3600 m/min (with the LV-0730 for sensor added) | ||||

| Measurement mode | Standard mode | |||

| Wide band mode | ||||

| Cutoff frequency | Standard mode | 5 kHz (LPF GAIN fc=-3 dB) | ||

| Wide Band mode | 20 kHz (LPF GAIN fc=-3 dB) | |||

| Maximum tracking acceleration | Standard mode | 800 m/s2 | ||

| 1,600 m/s2 (with the LV-0730 for sensor added) | ||||

| Wide Bandmode | No upper limit | |||

| Detection distance range | Standardmode | 0 to ±10000 m(cannot measured when LV-0732 selected) | ||

| Voltage Output in General | Number of output terminals | 2 | 4 | |

| Output terminal shape | BNC (receptacle) | |||

| Output voltage | ±10 V (20 V p-p) | |||

| Output impedance | 50 Ω or less | |||

| Output item | CH A velocity, CH A length | CH A velocity, CH A length | ||

| CH B velocity, CH B length | ||||

| A-B velocity, A-B length | ||||

| Velocity voltage output | Voltage range | 180 (m/min) /V | ||

| 50 (m/min) / V | ||||

| 10 (m/min) / V | ||||

| 1 (m/min) / V | ||||

| 360 (m/min) / V (sensor with LV-0730) | ||||

| 100 (m/min) / V (sensor with LV-0730) | ||||

| 20 (m/min) / V (sensor with LV-0730) | ||||

| 2 (m/min) / V (sensor with LV-0730) | ||||

| Measurement lower limit | 180 (m/min) /V | 0.23 m/min or less | ||

| 50 (m/min) / V | 0.063 m/min or less | |||

| 10 (m/min) / V | 0.013 m/min or less (Wide band mode: 0.026 m/min) | |||

| 1 (m/min)/ V | 0.0026 m/min or less (Wide band mode: 0.003 m/min) | |||

| 360 (m/min) /V | 0.46 m/min or less (sensor with LV-0730) | |||

| 100 (m/min) / V | 0.13 m/min or less (sensor with LV-0730) | |||

| 20 (m/min) / V | 0.026 m/min or less (Wide band mode: 0.052 m/min) (sensor with LV-0730)) | |||

| 2 (m/min)/ V | 0.0052 m/min or less (Wide band mode: 0.052 m/min) (sensor with LV-0730) | |||

| Linearity (DC offset excluded) |

180 (m/min) /V | Within ±0.2 % (F.S.) | ||

| 50 (m/min) / V | ||||

| 10 (m/min) / V | ||||

| 1 (m/min)/ V | Within ±0.3 % (F.S.) | |||

| 360 (m/min) /V | Within ±0.2 % (F.S.) | |||

| 100 (m/min) / V | ||||

| 20 (m/min) / V | ||||

| 2 (m/min)/ V | Within ±0.3 % (F.S.) | |||

| DC offset | Within ±0.3 % (F.S.) | |||

| Low-pass filter (LPF GAIN fc = -3 dB) | Standardmode | OFF (5 kHz) | ||

| 1 kHz | ||||

| 100 Hz | ||||

| Wide Bandmode | OFF(20 kHz) | |||

| 5 kHz | ||||

| 1 kHz | ||||

| 100 Hz | ||||

| Length Voltage Output | Voltage range | 1000 m/V | ||

| 100 m/V | ||||

| 1 m/V | ||||

| 100 mm/V | ||||

| 10 mm/V | ||||

| 1 mm/V | ||||

| 100 µm/V | ||||

| Linearity | Within ±0.3 % (F.S.) | |||

| DC offset | Within ±0.3 % (F.S.) | |||

Option

| Model | Product name | Description |

|---|---|---|

| LV-0703 | Sensor cable | Cable length 3 m |

| LV-0705 | Sensor cable | Cable length 5 m |

| LV-0730 | High-Velocity Module for Sensor | Detection velocity range: 0 to ±3600 m/min |

| LV-0732 | Additional Velocity Range | Velocity range: -270 to 3330m/min |

| LV-0740 | Channel modification | |

| LV-0752 | 90-Degree Beam Bending Mirror | |

| LV-0762 | Sensor Suspension Adapter | |

| LV-0773 | RESET IN Cable | One side open |

| LV-0774 | ERROR OUT Cable | |

| LV-0793 | Storage Trunk | Common for LV-7210, LV-7220 |

| LV-0015 | XY-axis fine-control stage | Stage face : 60 × 60 mm, travelling amount : ±6.5 mm |

| LV-0016 | Z-axis fine-control stage | Stage face : 60 × 60 mm, travelling amount : 0 to 13 mm |

| LV-0018A | Steel plate | |

| LV-0030 | Large magnet stand |

High-velocity module for sensor LV-0730

By attaching to the sensor, it realizes the detection velocity range of 0 to ±3600 m/min and extends the maimum tracking accelration to 1600 m/s2.

* Modification of the main unit is not required.

* Attachment/detachment to/from the sensor will be done in the factory of Ono Sokki. Please contact your nearest distributors or sales office.

LV-7002 + LV-0730

| Laser beam | ||

|---|---|---|

| Laser safety class | Class2 | |

| Measuring laser beam | λ =1,550 nm Less than 10 mW, CW oscillation |

|

| Guide laser beam | λ= 635 nm Less than 1 mW, CW oscillation | |

| Laser spot diameter | 2 mm x 1 mm, ellipse | |

| Detection distance | ||

| Detection distance (center) | 172 mm *from the bottom surface of the sensor | |

| Detection range (depth) | ±4 mm distance accuracy: within ±0.2 % (of reading) ±15 mm distance accuracy: within ±5 % (of reading) *Length evaluation by our standard plane at 25 °C |

|

| Sensor in general | ||

| Scale factor | Approx. 15 µm | *Reflected automatically at power-on. |

| Detection velocity range | 0 to ±3,600 m/min | |

| Maximum tracking acceleration | 1,600 m/s2 | |

| Outer dimensions | W 76 mm X H 40 mm X D 183 mm | |

| Weight of the main unit | Approx. 900 g (not including option/ cable) | |

Additional Velocity Range LV-0732

By offsetting the velocity range to the positive side, it enables switching of detection velocity range from the standard range of 0 to ±1800m/min to the range of -270 to +3330 m/min. Also, when it is combined with the LV-0730 High-velocity module for sensor, the velocity range can be extended to -540 to +6660 m/min.

| Detection Velocity in General | Detection velocity range | -270 to 3,330 m/min | |

|---|---|---|---|

| -540 to 6,660 m/min (sensor with LV-0730) | |||

| Maximum tracking acceleration | Standard mode |

800 m/s2 | |

| 1600 m/s2 (sensor with LV-0730) | |||

| Wide Band mode |

No upper limit | ||

| Velocity Voltage Output | Voltage range | 333 (m/min)/V | |

| 666 (m/min)/V (sensor with LV-0730) | |||

| Measurement lower limit | 333 (m/min)/V | 0.42 m/min or less | |

| 666 (m/min)/V | 0.84 m/min or less | ||

| Linearity (DC offset excluded) | Within ±0.2 % (F.S.) | ||

| DC offset | Within ±0.3 % (F.S.) | ||

| Output voltage | -0.811 V to +10 V | ||

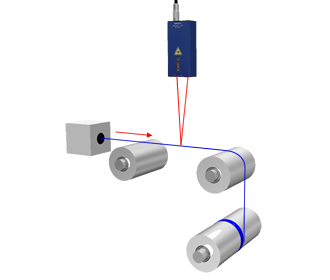

90-Degree Beam Bending Mirror LV-0752

It is an optical jig used to deflect a laser beam at an angle of ±90 degrees at a desired position. It supports laser emission to a target in a narrow space or in the gap between equipment to enable the measurement.

*It can be used when LV-0730 mounted.

*The detection range (depth) is ±8 mm.

Example

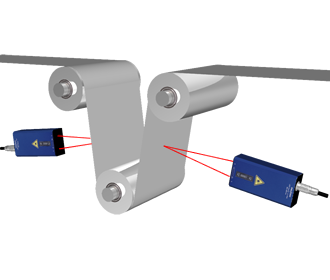

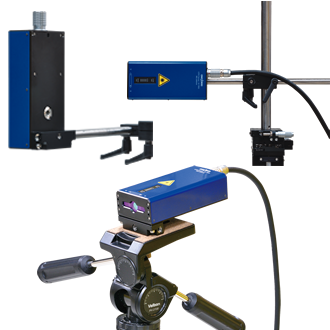

Sensor Suspension Adapter LV-0762

Attaching to the LV-7002 sensor increases the fixing positions, enables overhang of the sensor, suspension in an inverted manner, and four-way suspension of the sensor.

*It can be used when LV-0730 mounted.

Example