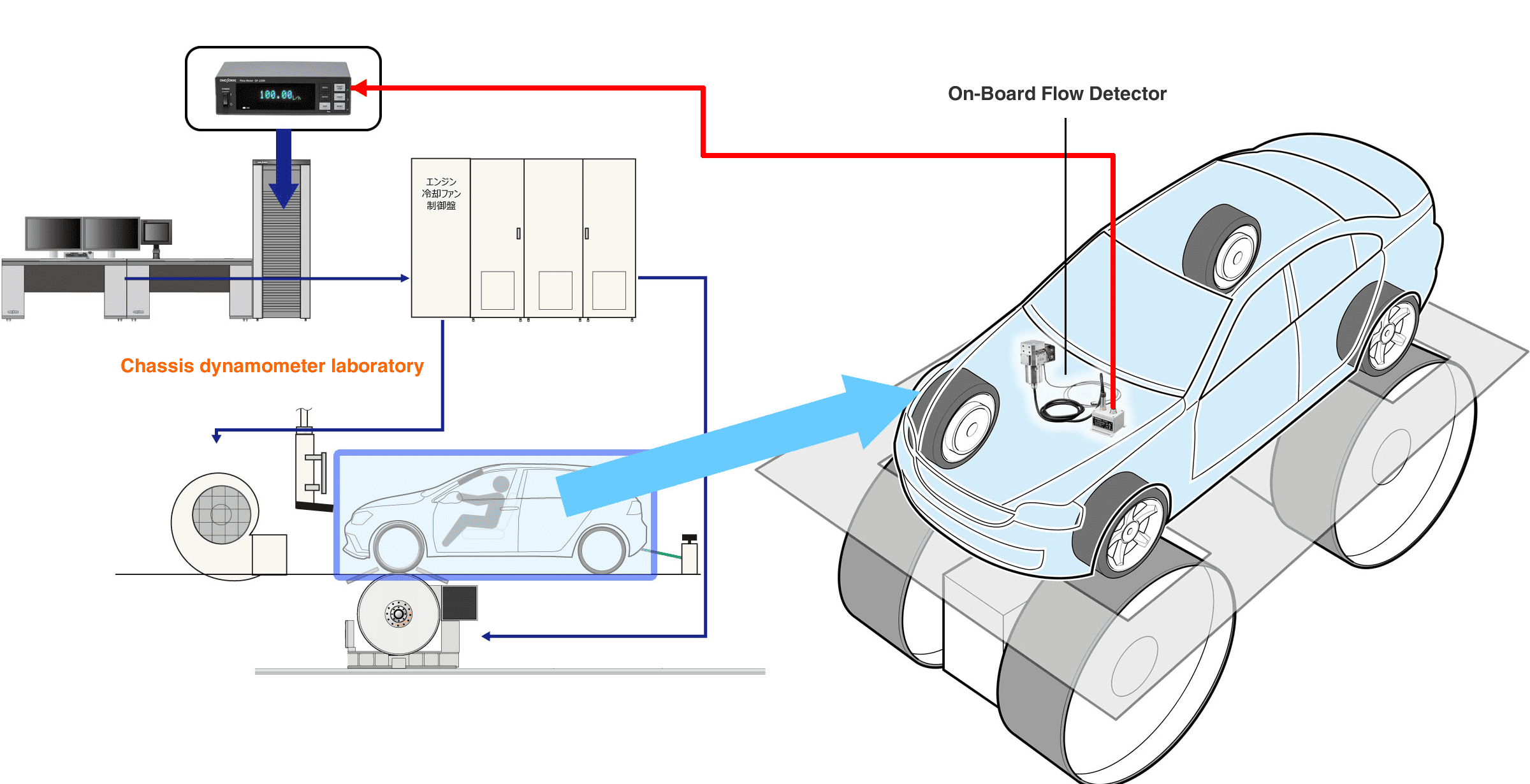

On-board flow measurement

Due to recent fuel consumption problems and changes in the environment surrounding automobiles,

the introduction of new test regulations, RDE (Real Driving Emissions) for driving on actual roads has being considered in Europe and Japan.

In automobile development, the demand for transient measurement such as "instantaneous" fuel consumption measurement during driving has been increasing.

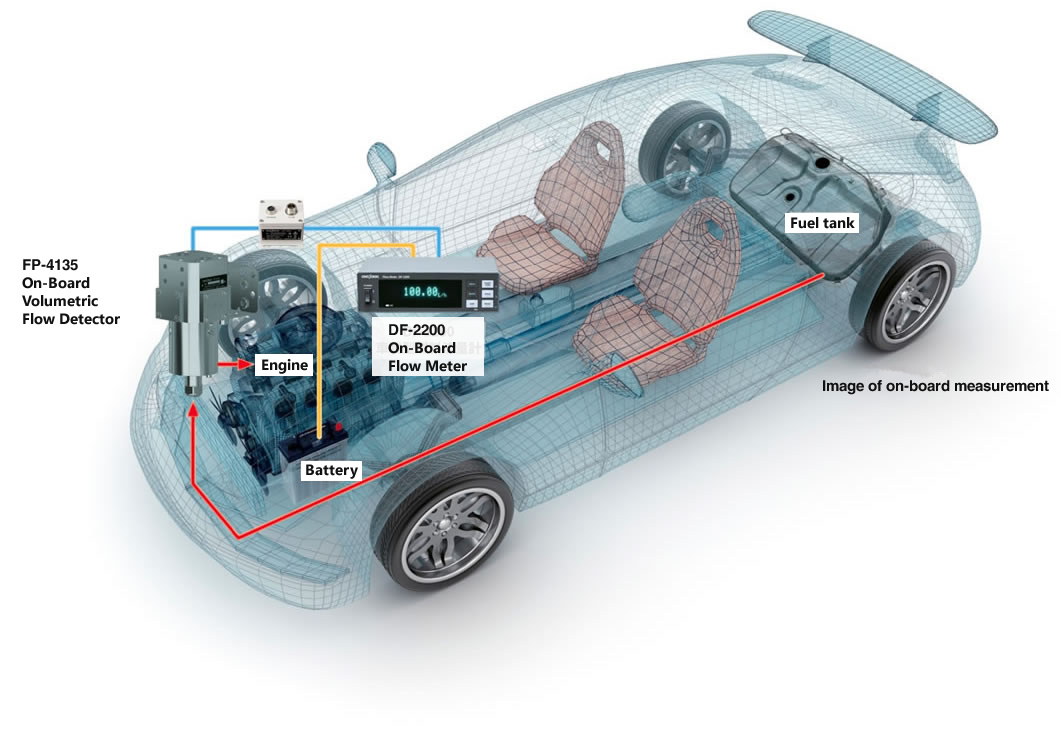

In the FP-4135/ DF-2200, the main measurement target is return less type engines, which have become the mainstream in gasoline-powered vehicles.

They are compact and have high functions so that they can be installed in the engine room and measure all types of fuel consumption of internal combustion engines.

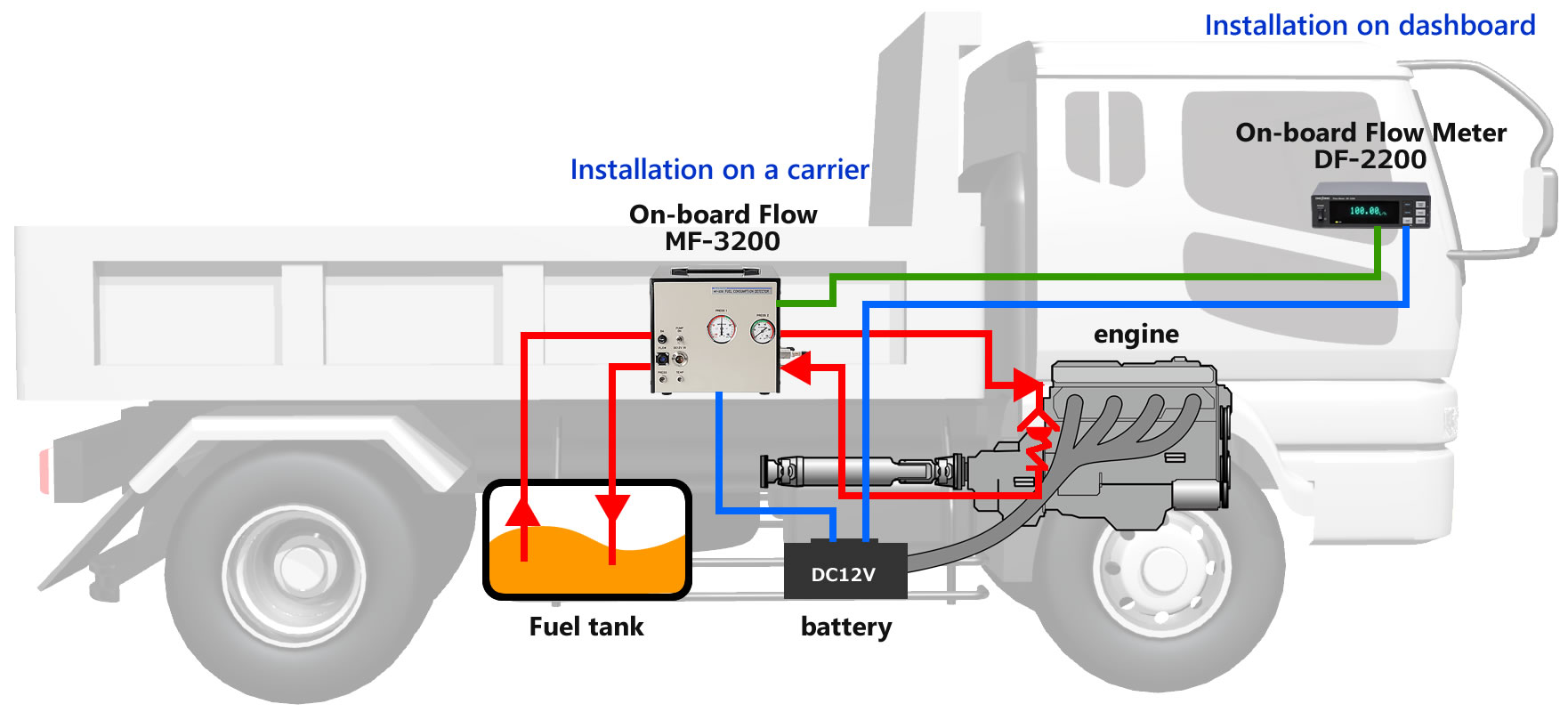

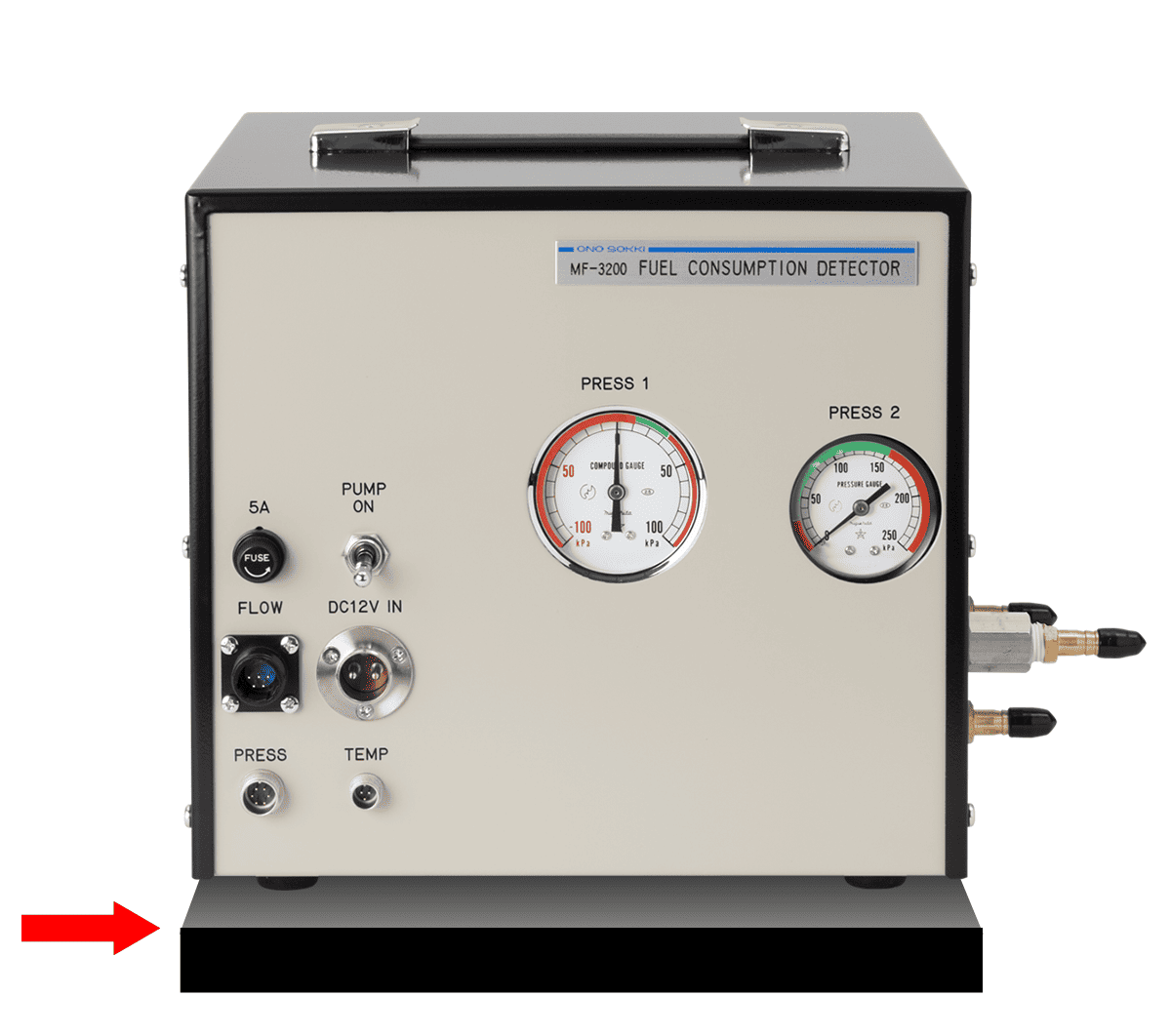

In the MF-3200, the measurement target is return type engines, such as diesel engines. Equipped with a system to process return fuel, it accurately measures fuel consumption and a cooling function of the return fuel,

it is possible to measure without changing the actual operating conditions of the engine.

Installtion guide

Precautions on installation of flow detector/flow meter

Be sure to check that the engine is stopped before installing or removing the detector/meter.

The engine right after it is stopped is at a very high temperature. Before installing or removing the detector/meter,

make sure that the engine is cooled off.

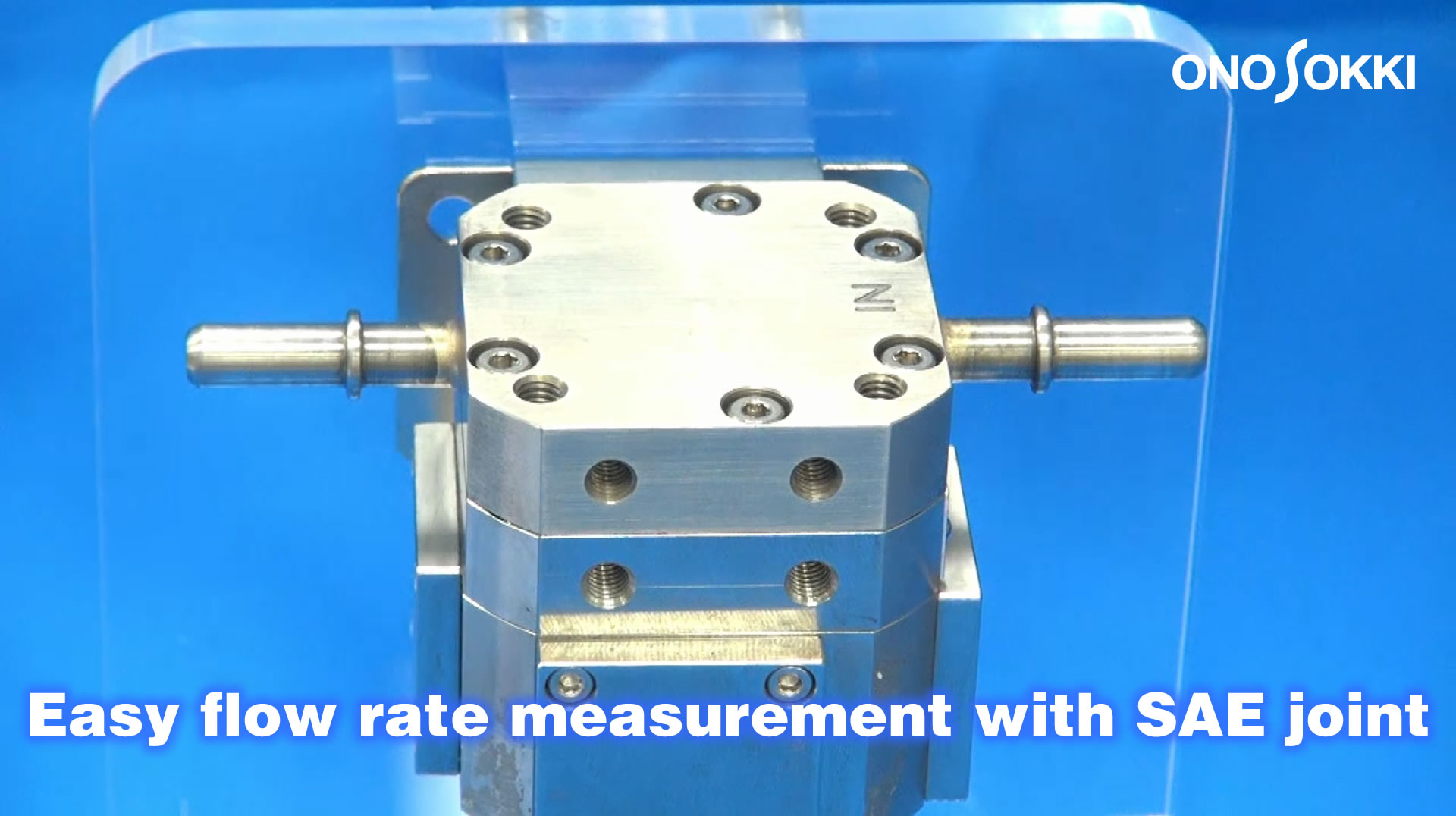

FP-4135 On-Board Volumetric Flow Detector

FP-4135 is a high precision equipment.

- Use in a place within the environmental temperature range (flow detecting part: -30 to +100°C, signal processing part: -30 to +70°C) with no large temperature fluctuations and within the specified vibration range.

- Install the detector in a upright position (within ±15 degrees).

- To mount the detector, use the fixtures of the detector or screws included in the product only.

- Install it at a lower position than the liquid tank to prevent the formation of air pockets and negative pressure.

*This does not apply when the fuel is pressurized and pumped with a fuel pump.

*To conduct measurement on public roads with a vehicle equipped with the FP-4135, you may require a permission from the local police or authorities concerned.For details, contact your local police station.

DF-2200 On-Board Flow Meter

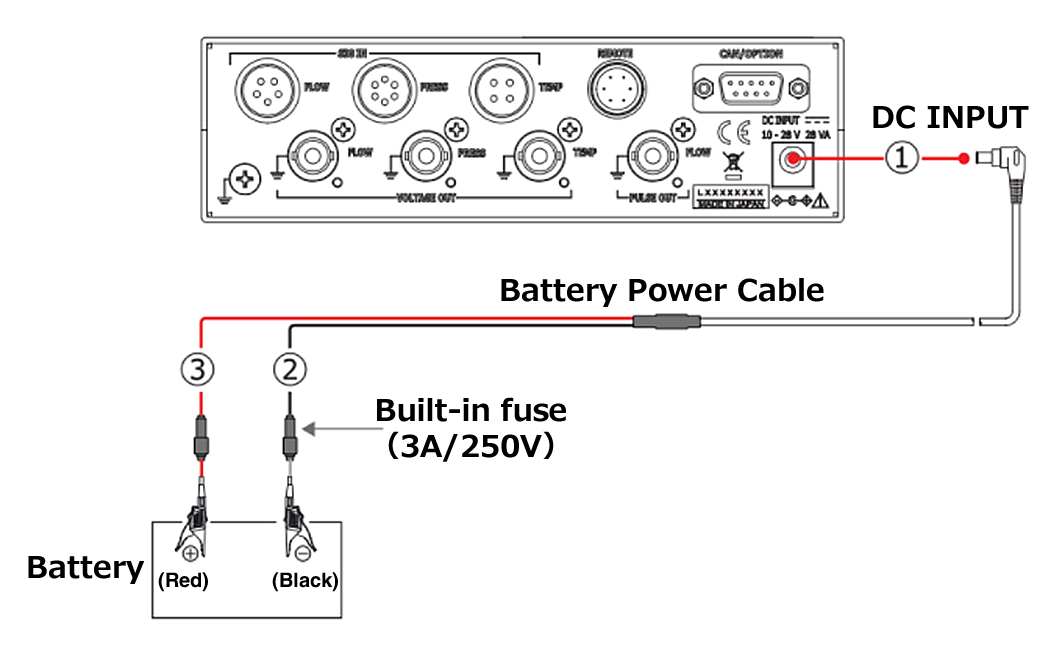

If power is supplied from a battery, use the supplied Battery Power Cable.

Connect the power cable to the battery as shown below.

- Check that the [POWER] switch of the DF-2200 On-Board Flow Meter is in the OFF ( ○ ) position.

- Connect the battery.

- First, securely insert the plug of the supplied Battery Power Cable into the power connector (DC INPUT) provided on the rear panel of the DF-2200 On-Board Flow Meter.

- Then, connect the black end of the Battery Power Cable to the pole and the red end of the Battery Power Cable to the pole of the battery terminal, respectively.

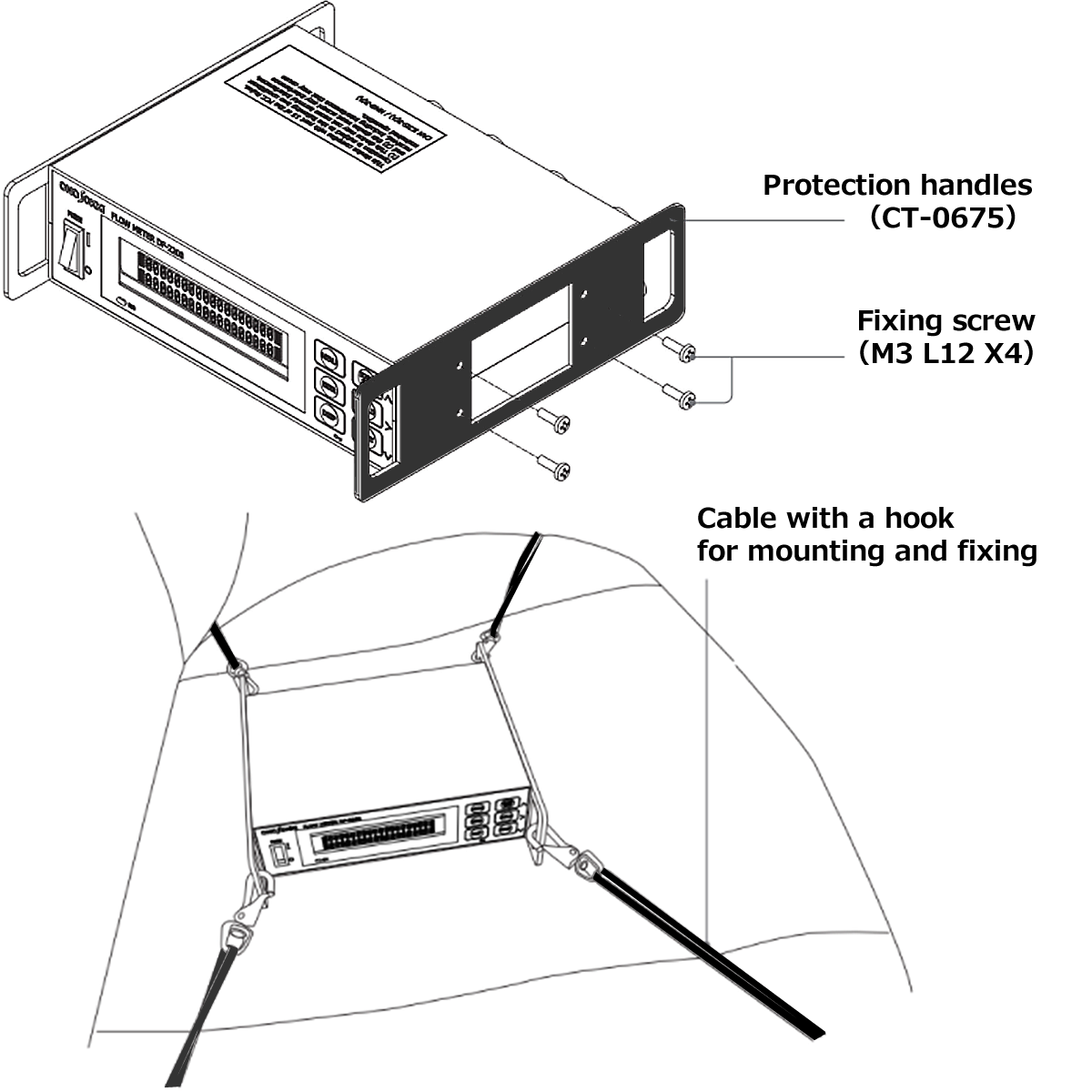

Install the DF-2200 On-Board Flow Meter on the passenger seat by referring to the illustrations and procedure shown below.

- Install the optional CT-0675 Protection handles on the DF-2200 On-Board Flow Meter. Secure the optional CT-0675 Protection handles using the supplied screws on the option installation screw holes on the right and left sides of the DF-2200 On-Board Flow Meter.

- Secure the DF-2200 On-Board Flow Meter on the passenger seat of the vehicle where the unit is installed.

Connect the cables with hooks to the CT-0675 Protection handles, then pull the cables to the right and left sides of the seat to firmly secure the unit so that it will not move suddenly.

* Do not use the DF-2200 main unit on a dashboard. If you use the DF-2200 main unit on a dashboard, it may drop during driving, resulting in injury or equipment damage.

Connecting to a battery

Installing on the passenger seat of vehicle

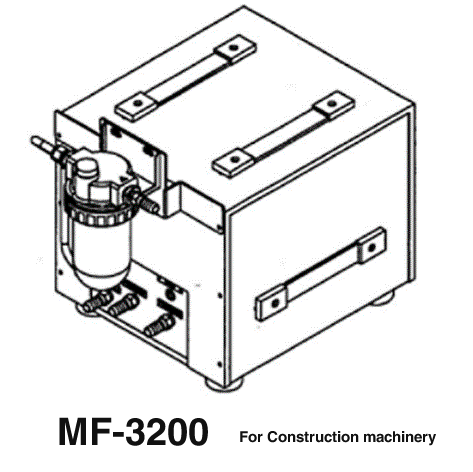

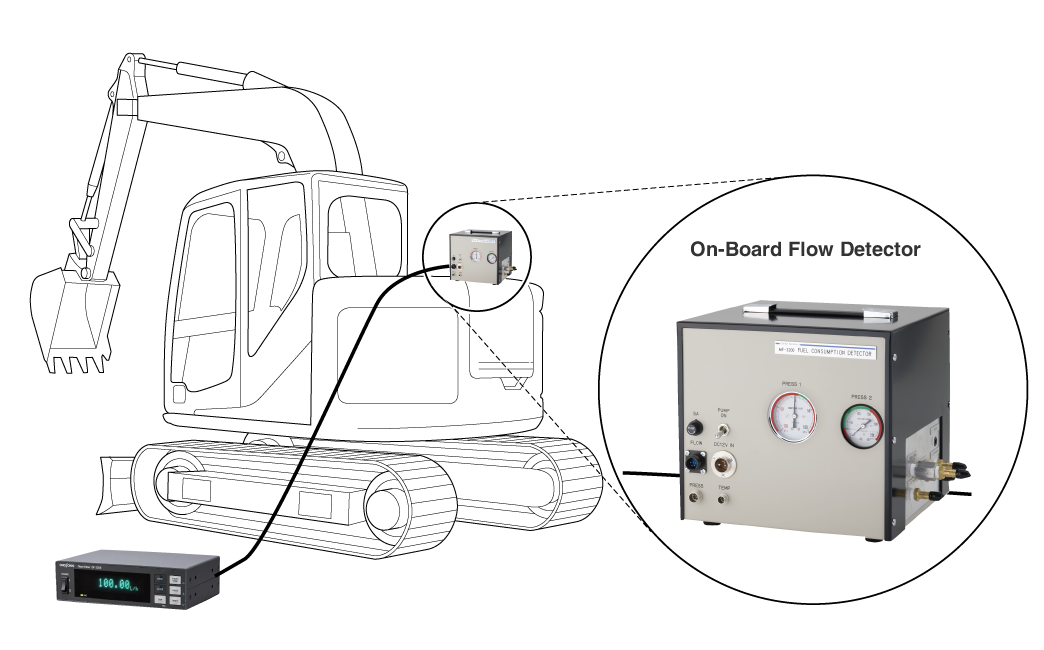

MF-3200 On-Board Flow detector

If the fuel returned from the engine is 80 °C or higher, cool the fuel off by inserting a heat exchanger.

* For construction equipment, it is possible to support large flow rates, larger filter inlets, DC12 V/24 V, and reinforced rubber feet. When installing in a vehicle, make sure to insulate the detector body and fix it firmly so that it does not directly contact with the vehicle.

Place a rubber sheet on the seat to insulate the detector.

Application examples

- Engine design, research and development departments such as automobile manufacturers, construction machinery manufacturers, and ship manufacturers

Example: Chassis dynamometer

Example: Construction machinery

Depending on the contents of test, the DF-2200 will be installed in the cabin or on the desk.

a) Excavation / loading operation test

Measure the fuel consumption or power consumption when performing a simulated operation of excavation/loading with a standard bucket attached.

b) Smoothing off operation test

Measure the fuel consumption or power consumption when performing smoothing off ground using a boom and an arm.

c) Travelling test

Measure the fuel consumption or power consumption when travelling on the flat straight paved road or sufficiently compacted land.

d) Standby operation test

As for fuel energy driven type hydraulic excavator and hybrid type hydraulic excavator,

measure the fuel consumption at the minimum engine load rotation speed during standby.

As for electric energy driven type hydraulic excavator, measure the power consumption required for standby operation specified by the manufacturer.

'(Quoted from JCMAS H020 : 2014 Earth moving machinery- Test methods for energy consumption - Hydraulic excavators

Related information

Last update2021/12/27