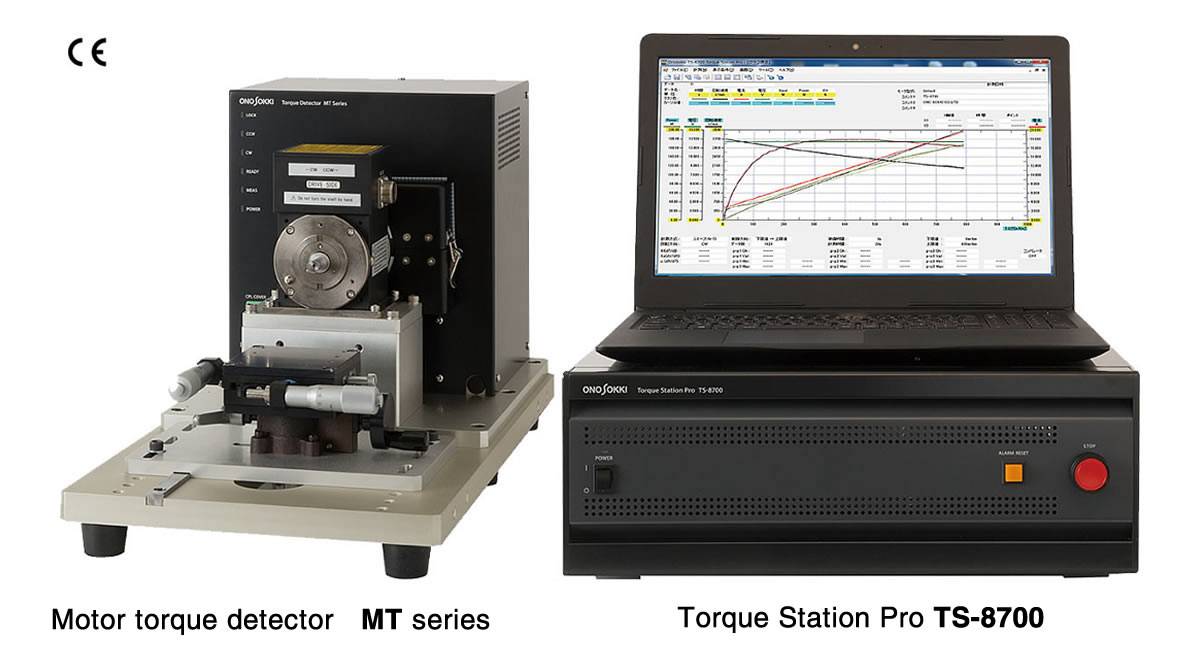

Torque Station Pro TS-8700

TS-8700 Torque Station Pro is torque measurement system for motor basic property with high precision and high response.

In combination with the motor torque detector MT series with the TH series torque detector, it is possible to perform high-precision,

high-response motor torque measurement with up to 5.12 kHz sampling and ± 0.1 % of accuracy.

In addition, the high rigidity compact torque detector RH series (10 N・m/ 20 N・m) can be mounted on the MT series. It has achieved more highly accurate measurement with ±0.05 % FS

This system is ideal for measuring torque fluctuations of motors on-board such as EPS motors.

- Switching function of motor torque detector is built-in.

- 2 channels as standard, up to 4 channels as options

- Various types of detectors (MT series) for the TS-8700 are available to support various motor characteristic measurement

- Selectable from three series according to the purpose; for high speed rotation motor, large capacity motor, and torque ripple/cogging torque. There are three types including general, high performance and high precision, and 58 models in total.

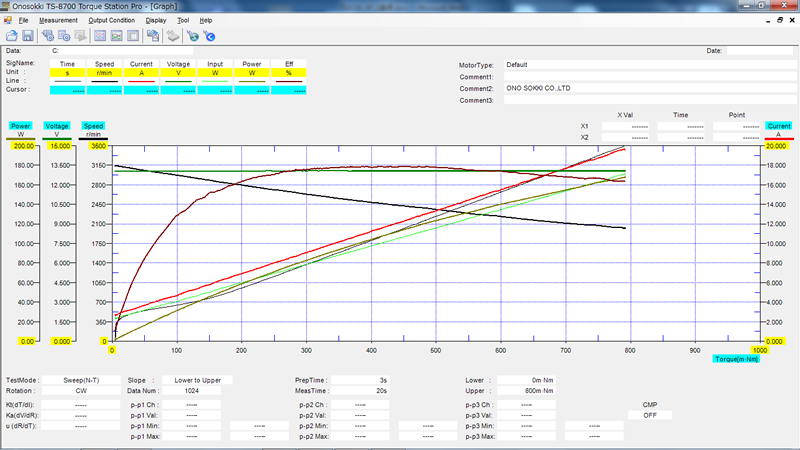

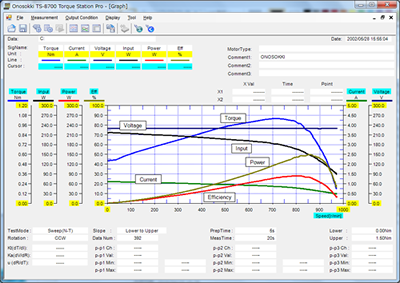

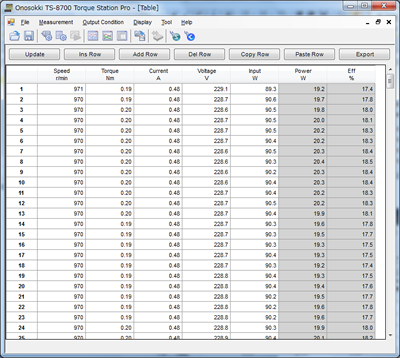

Data example

Calculation display of efficiency

(Required current voltage detector separately)

Can be used in a software for word processing or spreadsheet

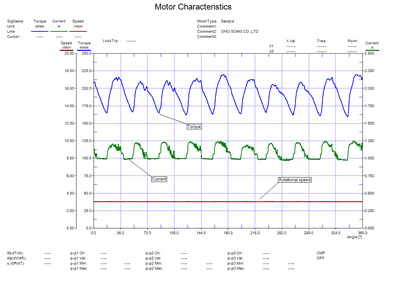

Measurement data of torque ripple

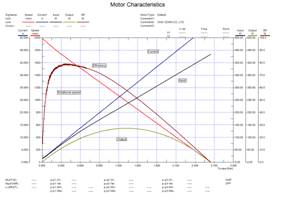

Measurement data of Revolution-Torque characteristics

Application example

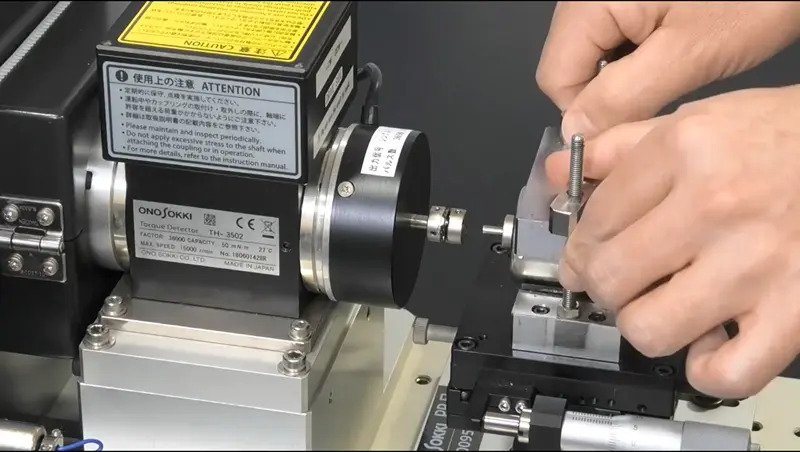

Measuring torque characteristic of DC motor

· The above example shows how to measure and display as graphs the characteristics of DC motor of torque, rotational speed, current, voltage. The efficiency performed by internal calculation also can be displayed.

· The DC Voltage/current detector (made to order) or Power meter is required.

Customer Reviews

Application example of torque detector and motor basic characteristic measurement system

Microtech Laboratory Inc.

Direct drive motor that has characteristics of low rotation speed and high torque

Achieves highly accurate operation to eliminate cogging torque

System configuration

Overview specification

| Measurement target | DC motor, AC motor (excluding stepping motor) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Measurement parameter | Torque, rotation, voltage signal input data, temperature*,rotation angle*,power meter digital input* | ||||||||

| Torque input | Use signals form Ono Sokki’s exclusive detector (MD/SS,TH/RH/TQ*) , external torque analog input* | ||||||||

| Revolution input | Use signals form Ono Sokki’s MP-981 or RP series detectors | ||||||||

| Analog input | 0 to ±10 V DC, 16 channels, 16 bit A/D Connection cable: customer prepared | ||||||||

| Temperature input | Type T thermocouple* T-type thermocouple: customer prepared | ||||||||

| Measurement accuracy |

Torque** | ±0.05 % FS(RH,TQ*) ±0.1 % FS(TH-1000/2000 ) ±0.2 % FS(MD/SS、TH-3000/H) |

|||||||

| Revolution speed** | MT-84M/T/R series, MT-85M/T/R series ±0.02 % FS ±1 count MT-82T, excluding MT-82T15, MT-82T25 ±0.06 r/min MT-82M, MT-82T15, MT-82T25,MT-82R15,MT-82R25 ±0.02 r/min |

||||||||

| Analog | Linearity : ±0.1 % FS Or less(1 second average), temperature drift:±0.01 % FS/°C | ||||||||

| Temperature | Conversion accuracy : within ±[0.5 % of span + 0.5 °C {thermosensitive element accuracy}] Temperature drift : ±0.2 % or less of span to the change of 10 °C |

||||||||

*: Option

|

|||||||||

| Computing equation | Four arithmetic expression (The operation items can be defined by input signals and existing calculatd data.) | ||||||||

| Measurement condition setting | Setting of torque detector, revolution detector |

||||||||

| Control method | Revolution/torque Measurement mode: Automatic/manual Can be saved with a file name. |

||||||||

| Measurement function | ◎Fixed value measurement: |

measurement time | 2 to 28,800 seconds | ||||||

| Number of data | • SS/MD:512/1024/2048/4096/8192/angle Sample • TH :2048/4096/8192/16384/32768/Sample • TH high response (available when TS-0871 option installed) :10240/20480/40960/81920/163840/Sample • RH/TQ (available when TS-0882 option installed) :10240/20480/40960/81920/163840/Sample • EXT TRQ IN (available when TS-0873 option installed) :512/1024/2048/4096/8192/Sample (Angle Sample: available only when manual operation (N) , and the measurement time is limited to 60 seconds or 120 seconds.) |

||||||||

| ◎Sweep measurement | measurement time | Depending on the number of data. 512 : 2 to 1000 seconds 1024 : 4 to 1000 seconds |

|||||||

| Number of data | • SS/MD : 512 / 1024 • TH : 2048 / 4096 • TH high response (available when TS-0871 option installed) : 10240 / 20480 • RH/TQ (available when TS-0882 option installed) : 10240 / 20480 • EXT TRQ IN (available when TS-0873 option installed) : 512 / 1024 |

||||||||

| ◎Step measurement | Number of steps | 2 to 128 Calculated automatically from the upper/lower limit torque or upper/ lower limit rotation speed and step width. |

|||||||

| Step time | 5 to 100 seconds | ||||||||

| ◎Pattern measurement | Number of patterns | 1 to 128 | |||||||

| Number of repeat times | 1 to 10 | ||||||||

| Shift time | 1 to 100 seconds | ||||||||

| Monitor display | Numeric value display : Max. 100 items can be displayed simultaneously Trend display:Time axis display |

||||||||

| Graph display | Display by specifying X-axis, Y-axis from the measured data Graph enlargement/reduction, specifying line color/line width, comment input, text display and text saving on the graph, cursor/peak search function, overlay display function, max. 16 files |

||||||||

| Table display | List display of measured value, data edition function | ||||||||

| Comparator | Upper/lower limit of selected items can be specified, max. 4 points to max. 6 items, display and output of judgment result | ||||||||

| I/F for MT series detector | 2 channels, (4 channels as an option) | ||||||||

| Saving measurement results | Data saved in an exclusive format or text format | ||||||||

| Operating environment of a PC | PC specification that TS-8700 software can be operated on

|

||||||||

| Power requirement | AC100 to 240 V± 10 %, 50/60 Hz | ||||||||

| Power consumption | Approx.200 VA (AC100 V) or less | ||||||||

| Isolation resistance | 10 MΩ or more (rated voltage DC 500 V) | ||||||||

| Withstand voltage | AC 1500 V for 1 minutes | ||||||||

| Temperature/humidity | Operating temperature range: + 5 to + 35 °C | ||||||||

| Operating humidity range: + 30 to + 80 %RH (with no condensation) | |||||||||

| Storage temperature range: − 10 to + 55 °C | |||||||||

| Storage humidity range: + 30 to + 80 %RH (with no condensation) | |||||||||

| Altitude condition etc. | Pollution degree: 2 Installation category: Category 2, indoor useMax. altitude: 2000 m With no condensation Without no corrosive gas |

||||||||

| Outer dimensions | 420 (W) x 149 (H) x 450 (D) mm or less | ||||||||

| Weight | Approx. 15 kg | ||||||||

| Conforming standard |

MT-0100 series, MT-071 series: RoHS not supported |

||||||||

| Accessory | AC power cord, application CD-ROM, LAN cable (2m) | ||||||||

| Others | *MT series detector and detection stand for motor etc are required separately. * Adjustment fee is separately required for matching to the MT series detector. |

||||||||

Option

| TS-0871 |

TH highly responsive sampling | Adds the highly responsive sampling function of the TH detector (supports 5120 Hz) |

|---|---|---|

| TS-0872 |

Analog/pulse output | Adds torque/rotation speed analog output, and rotation speed pulse output function. |

| TS-0873 |

External torque/analog input | Required when the torque control is used in the analog output of the torque detector. |

| TS-0874 |

Additional detector interface | Connects four or more MT series torque detectors |

| TS-0875 |

Interface for BA-910A | Required when the BA-910 type power amplifier is used. |

| TS-0876 |

Temperature measurement/temperature trigger | Required for temperature measurement. • Eight connectors (male) for sensor side are provided as standard. |

| TS-0877 |

Angle measurement/angle sampling | Adds the angle sampling function of external encoders •Cable side connector (ER03-PB8M) is provided as standard. |

| TS-0878 |

Link to DS-3000 | Links to DS-3000 series made by Ono Sokki |

| TS-0881 |

Power meter digital communication | Connects to power meter made by other company via LAN, and loads the measurement values digitally. |

| TS-0882 |

Additional TQ/RH detector | It can connect the TQ/RH series torque detectors. |

Related information

Last update : 2025/08/29