Torque Detector RH series New

The RH series makes torque measurement range wider beyond expectation.

As the shift to electrification of various products, the development of quieter and higher quality motors has been required.

The RH series can accurately detect torque fluctuations with high rigidity,

and supports high-speed rotation.

It helps the development of products with outstanding quietness

by minimizing cogging torque and torque ripple that cause vibration and noise.

Feature

High rigidity: Highly accurate detection of torque fluctuation with high response

The RH series is a torque detector that can accurately detect torque fluctuations with high torsional rigidity about 4.5 times compared to the existing products .

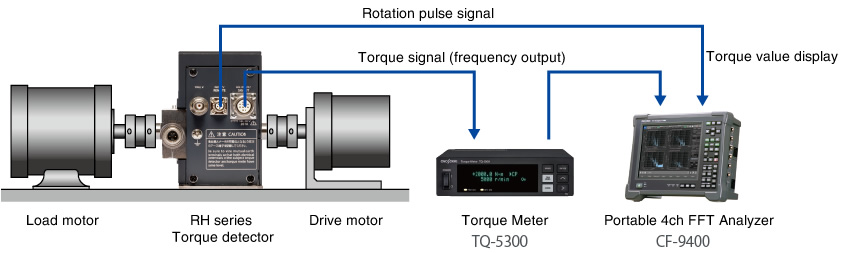

Example of RH series cogging torque measurement (compared to a general torque detector)

This is an example of measuring cogging torque of the RH torque detector and a general torque detector with the CF-9400 FFT analyzer.

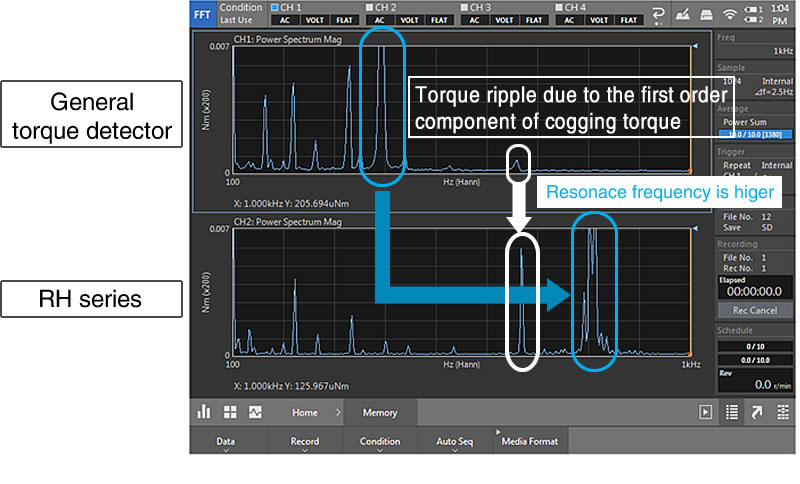

The power spectrum above shows the measurement result of the cogging torque of the RH series and a general torque detector.

The RH series has higher torsional rigidity than general detectors, and also its resonance frequency is higher. The torque measurement (the torque ripple due to the first order component of cogging torque) can be performed with higher accuracy. In addition, it enables to measure flat and higher frequency.

High speed torque measurement: Rotation speed up to 20,000 r/min

In motors of EV scooters and compressor for air conditioners, the demand for high-speed rotation has been increasing as well.

The RH series provides high-speed rotation measurement up to 20,000 r/min and stable measurement from low (*) to high speed rotation.

(2.5 times faster than the existing models)

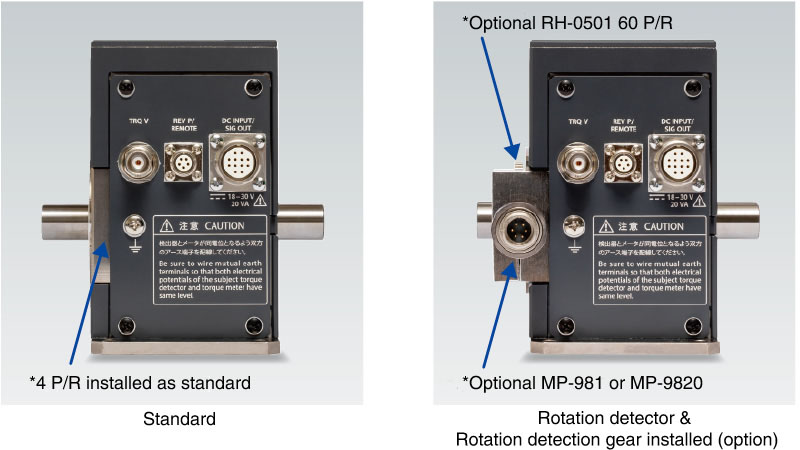

Installation example of rotation detector

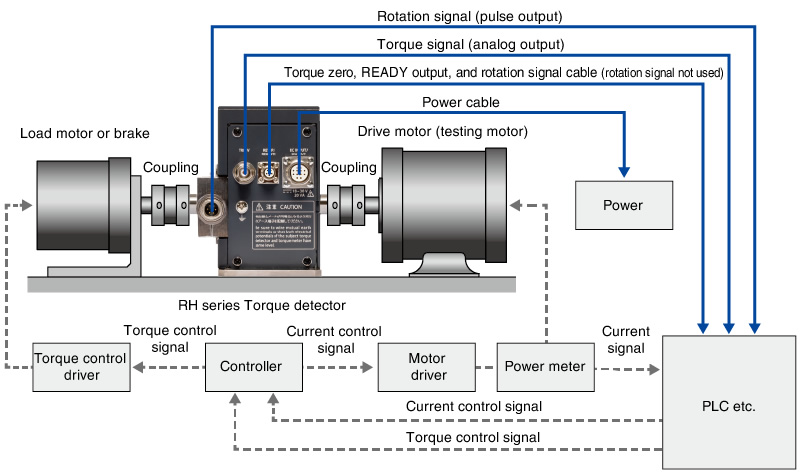

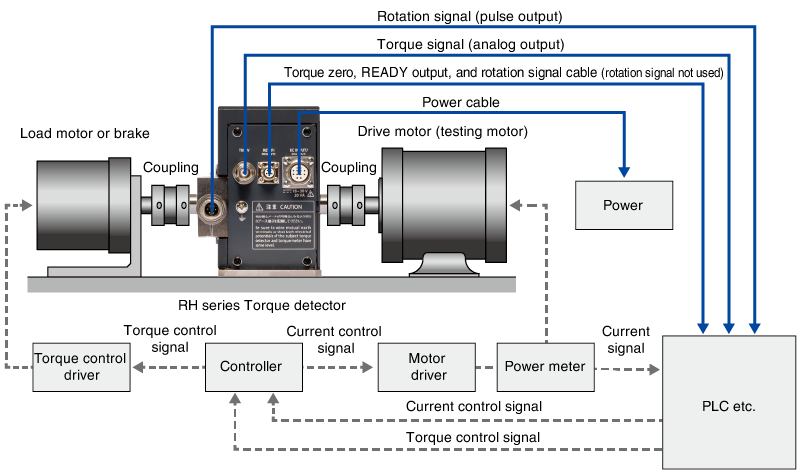

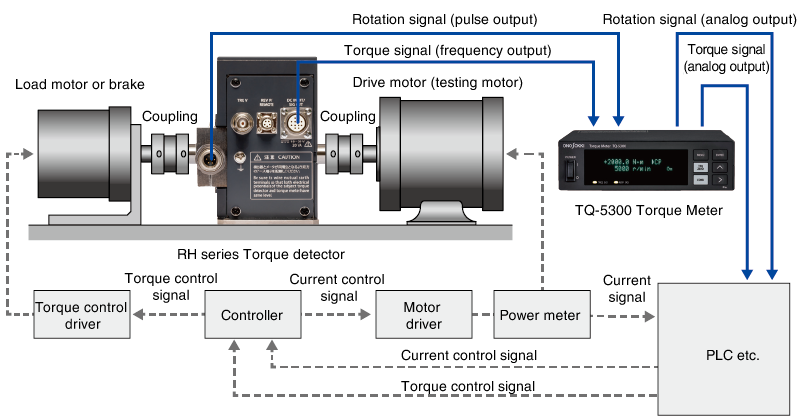

Direct signal output: Ideal for installing into system

RH series can be used as a stand-alone torque detector without a display unit and the direct signal output has achieved cost saving.

Example of system configuration

High accuracy: Perform performance evaluation tests of motors and other equipment with high accuracy

The RH series torque detector has achieved highly accurate measurement with ±0.05%/FS of linearity including hysteresis (1/2 compared with the existing models).

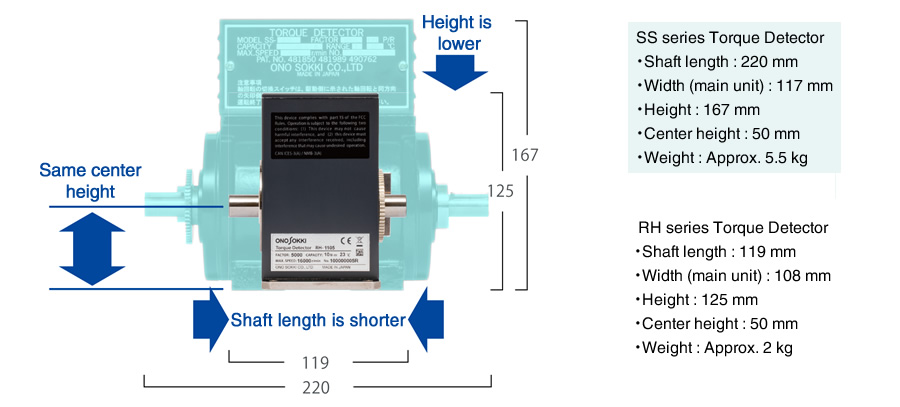

Compact: Weight and volume are reduced to about 1/3 compared to the existing models

Smaller and lighter than the existing models and having the same center height to easily replace and handle.

Comparison of dimensions with SS series

Example of system configuration

RH series Torque Detector alone

RH series Torque Detector connecting with the TQ-5300 Torque meter

Customer Reviews

Application example of Torque Detector RH series

The Graduate School of Frontier Sciences, The University of Tokyo

Custom Motor Bench for Investigating and Minimizing Iron Loss

Specifications

| RH-1105 | RH-1205 | ||

|---|---|---|---|

| Torque Detection | Rated torque | 10 N・m | 20 N・m |

| Breakdown torque | 400 % or more of rated torque | ||

| Limit torque | 200 % or more of rated torque | ||

| Linearity | ±0.05%/ FS or less (screen display with TQ-5300 connected) | ||

| Influence on temperature at zero point | ±0.02 %/FS/°C or less (screen display with TQ-5300 connected) | ||

| Influence on temperature at span point | ±0.02 %/FS/°C or less (screen display with TQ-5300 connected) | ||

| Rotation speed detection | Number of output pulses (standard) | 4 P/R (detected with hall IC and magnet) | |

| Number of output pulses (optional RH-0501 rotation detection gear 60 P/R mounted) |

60 P/R (optional MP-981 or MP-9820 used for rotational speed detection) |

||

| Analog torque output | Output format | Voltage output 0 to ±10 V/F.S |

|---|---|---|

| Analog conversion method | Cycle conversion method (converted to torque value at each cycle and then converted to analog voltage) |

|

| Minimum allowable load | 100 kΩ | |

| Linearity | ±0.10 %/FS or less | |

| Zero point offset | 0.05 V or less | |

| Connector | BNC (female) | |

| Torque frequency output | Output format | Line driver output 10 kHz ±5 kHz |

| Connector | R03-RB12F | |

| Rotational speed pulse output | Output item | Hall IC pulse output on which waveform shaping is processed |

| Output format | Open collector output with pull-up to +5 V by 330 Ω resistor | |

| Minimum allowable load | 10 kΩ | |

| Connector | R03-RB5F |

| Torque zero input | Input item | Torque zero correction value acquisition start Contact input; Makes a torque at no-load zero automatically through external contact. |

|---|---|---|

| Input signal | No-voltage contact input Open voltage: 5.25 V or less Short-circuit current: 1 mA or less | |

| Connector | R03-RB5F | |

| READY output | Output item | Contact output: Contact closes in the torque measurement state. |

| Output format | Photo MOS relay | |

| Load voltage | DC 30 V or less | |

| Load current | 100 mA or less | |

| ON-resistance | 10 Ω or less | |

| Connector | R03-RB5F |

| RH-1105 | RH-1205 | |||||||

|---|---|---|---|---|---|---|---|---|

| Power supply voltage | DC 24 V (8-30 V) | |||||||

| Power consumption | 20 W or less | |||||||

| Power input connector | R03-RB12F | |||||||

| Operating temperature range | 0~+50 °C *1 | |||||||

| Operating humidity range | 20 to 85 %, no dew condensation*1*2 | |||||||

| Storage temperature range | -10~+60 °C *1 | |||||||

| Storage humidity range | 20 to 85 %, no dew condensation*1*2 | |||||||

| CE marking |

|

|||||||

| FCC | FCC Part 15 Subpart B Class A | |||||||

| ICES | ICES-003 Issue6 + Amendment1 ClassA | |||||||

| Safety | IEC61010-1: Overvoltage category I, grounding protection class III, contamination level 2 | |||||||

| Torsional rigidity (design value) | 10 N·m : 3.6 kN·m/rad |

20 N·m : 6.9 kN·m/rad | ||||||

| Inertia moment (design value) | 10 N·m : 24.3×10-6 kg·m2 | 20 N·m : 24.6×10-6 kg·m2 | ||||||

| Rated rotational speed (standard) | 16,000 r/min | |||||||

| Rated rotational speed (with optional RH-0502 dynamic balance adjusted) | 20,000 r/min | |||||||

| Supplied items | Instruction manual, Inspection chart, Key | |||||||

*1: When exposed to a high temperature environment for a long time, it may affect the zero torque value. Avoid long-time exposure or correct for zero torque before usage.

*2: Avoid a hot and humid place for long-time continuous use or storage. It may affect the performance.

Options

| Model | Name |

|---|---|

| RH-0105 | Torque signal cable (5 m) |

| RH-0110 | Torque signal cable (10 m) |

| RH-0205 | Power cable (5 m) |

| RH-0210 | Power cable (10 m) |

| RH-0305 | Rotation signal cable (5 m): for connecting RH series with TQ-5300 series |

| RH-0310 | Rotation signal cable (10 m): for connecting RH series with TQ-5300 series |

| MX-7105 | Rotation signal cable (5 m): for connecting MP-981/9820 with TM-3000 series |

| MX-7110 | Rotation signal cable (10 m): for connecting MP-981/9820 with TM-3000 series |

| MX-8105 | Rotation signal cable (5 m): for connecting MP-981/9820 with TQ-5300 series |

| MX-8110 | Rotation signal cable (10 m): for connecting MP-981/9820 with TQ-5300 series |

| RH-0405 | Torque zero input cable (torque zero, READY output, and rotation signal cable) 5m |

| RH-0410 | Torque zero input cable (torque zero, READY output, and rotation signal cable) 10m |

| RH-0501 | Rotation detection gear 60 P/R |

| MP-981 | Magneto-electric rotation detector |

| MP-9820 | Magneto-electric rotation detector |

| RH-0502 | Dynamic balance adjustment |

| MX-101 | Signal cable (1.5m) |

| MX-105 | Signal cable (5m) |

Related information

Revised:2021/10/20