High-precision Fuel Flow Measurement System

When evaluating the effect of changing parts and control methods in engine tests, it will be difficult to determine whether the effect is due to the changes themselves or not if the external environment such as fuel temperature and pressure is not stable. Our high-precision fuel flow measurement system realizes the fuel flow measurement with high accuracy by controlling the fuel temperature and pressure supplied to the engine.

Features

Stable temperature control

It enables to keep the temperature fluctuation of the circulation flow path in the system within ±0.2 °C (for 1 minute), which achieves stable fuel flow rate measurement.

Shorten bench-up time with automatic air purging device (option)

The automatic air purging device can be built in the system as option, shortening the bench-up time until the start of measurement.

Flexible customizing

We can customize the system according to the user requirement such as return processing and the circulated flow rate that meets heat capacity for each test engine.

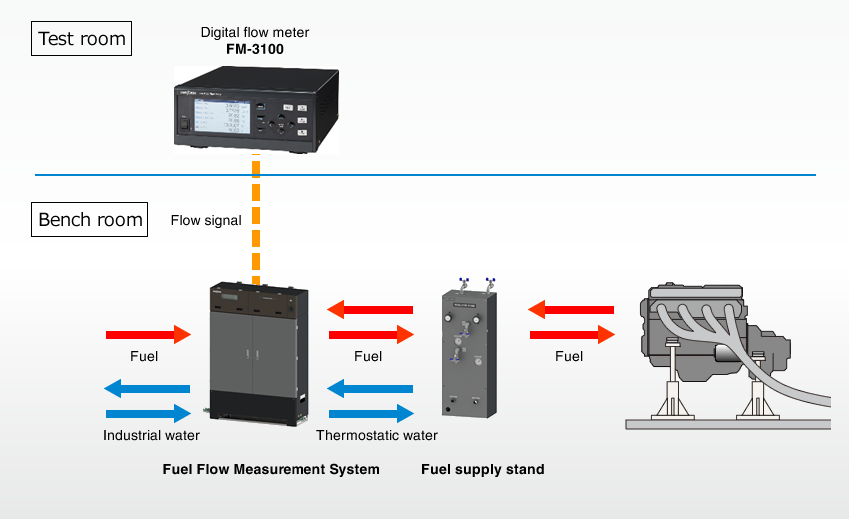

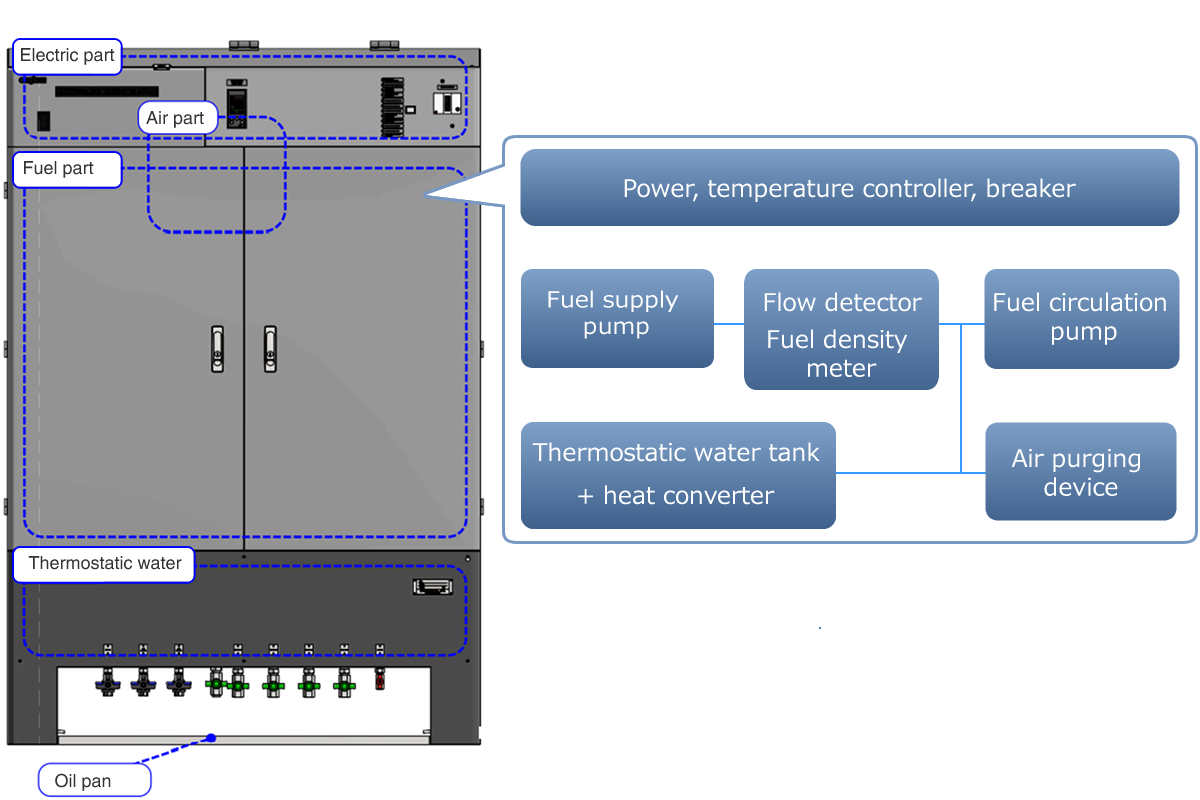

System configulation

Specifications (one of example)

| Usable liquid | Gasoline, light oil*, mixture of ethanol and gasoline, ethanol *Biodiesel fuel can be used, but not all are guranteed. Some light oils cannot be used as the wax components precipitate when the liquid temperature is near zero degrees, which may cause clogging of the filter. The same is for alcohol fule. |

|

|---|---|---|

| Measurement items | Flow rate, temperature, density | |

| Measurement range | Flow rate | 0.3 to 300 L/h |

| Temperature | 0 to 99.9 °C | |

| Density | 0.5 to 2.0 g/cm3 | |

| Accuracy | Flow rate | Within ±0.2 % of reading |

| Temperature | Pt 100 Ω Class A | |

| Density | ±0.0010 g/cm3 (light oil, Cleansol HS at 20 °C) | |

| Temperature control accuracy | Within setting temperature ±1 °C (constant mode) | |

| Temperature control stability | ±0.2 °C (for one minute) | |

| Operating temperature | 0 to 40 °C | |

| Weight | Approx. 200 kg (excluding stand) | |

*Pleaes contact us about the specifications other than above.