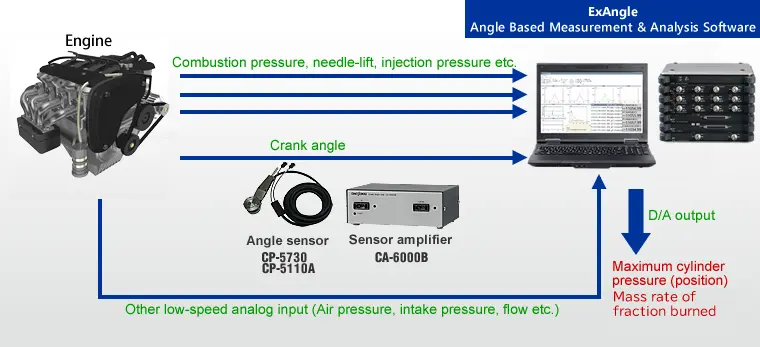

Angle Based Measurement & Analysis Software

ExAngle UPDATE

Combustion Analysis Software creates efficient development environment

The ExAngle has been reorganized based on the combustion analysis measurement technology that we have accumulated over many years, and has been reborn as the system that handles high-speed sampling measurement data for any rotating objects, not just internal combustion measurement.

EX-4100 ExAngle

This is basic software that uses a 1MHz high-speed unit for combustion analysis and can record with a minimum resolution of 0.05 degree.

DS-0328T Transient combustion analysis function

DS-0335 SYNC measurement function

DS-0349 Crank angle pulse period measurement function

DS-0360 Encoderless measurement function

EX-0428 DS Combustion Analysis Function

All the calculation functions of the following existing products are included,

such as indicated mean effective pressure, combustion mass fraction burned,

combustion variation rate, knocking peak, combustion noise, and torque.

DS-0328 Combustion Analysis Software

DS-0337 Combustion noise analysis function

DS-0329 Knocking analysis function NEW

DS-0361 Torque fluctuation analysis NEW

EX-0436 DS Combustion Link Function

The ExAngle is controlled from the bench system via LAN communication. It can control to recording and data transmission/reception.

EX-0483 CAN Function

The results of ExAngle calculations can be sent to the CAN bus, and CAN information from the vehicle can be received and recorded.

EX-0439 Knocking Expert Function NEW

By measuring engine noise with a microphone, knocking can be quantitatively indexed.

Features

- It can be used not only for combustion analysis but also for more general-purpose high-speed angle sampling measurement.

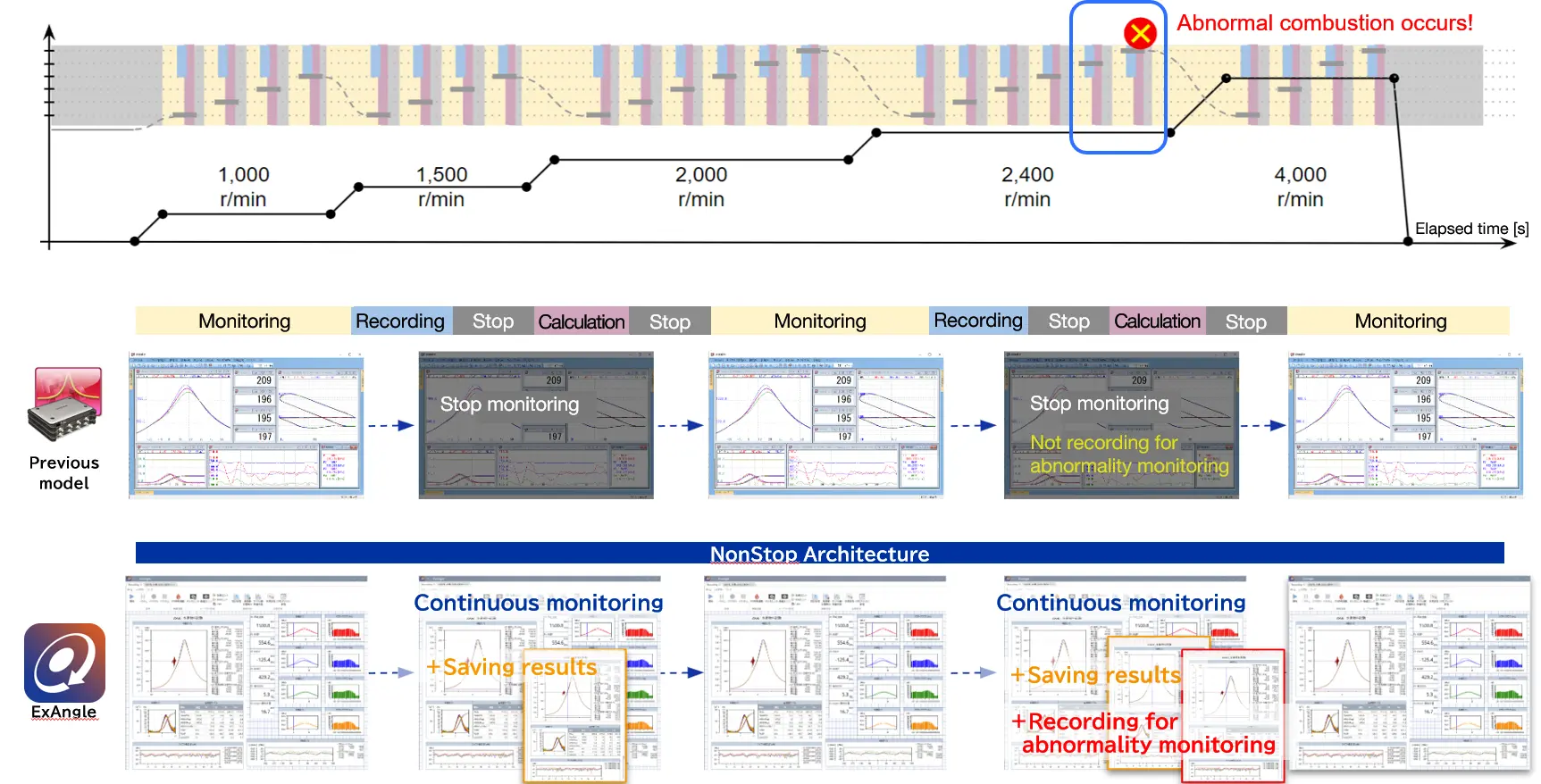

- The NonStop architecture allows constant monitoring even during hazardous testing.

- In addition to the main recording, sub-recording can be operated simultaneously, thus you won't miss any unexpected sudden phenomena.

- The intuitive GUI reduces tester errors. It is also useful for outsourcing testing operations and expanding overseas.

Combustion Analysis System Configurations

NONSTOP monitoring + Sub-recording enhances fuel test monitoring.

In order to achieve carbon neutrality, the evaluation and verification of new fuels and new devices have been increasingly important. With the ExAngle, testing can be carried out safely and efficiently even with limited development resources.

The ExAngle does not stop monitoring even during calculations after data recording or when saving files, thus testers can carry out their work with peace of mind. In addition, sub-recording for abnormality monitoring can be performed in parallel with normal main recording, making it possible to preserve abnormality data while protecting equipment.

Allowable rotational speed and the maximum number of recording cycles

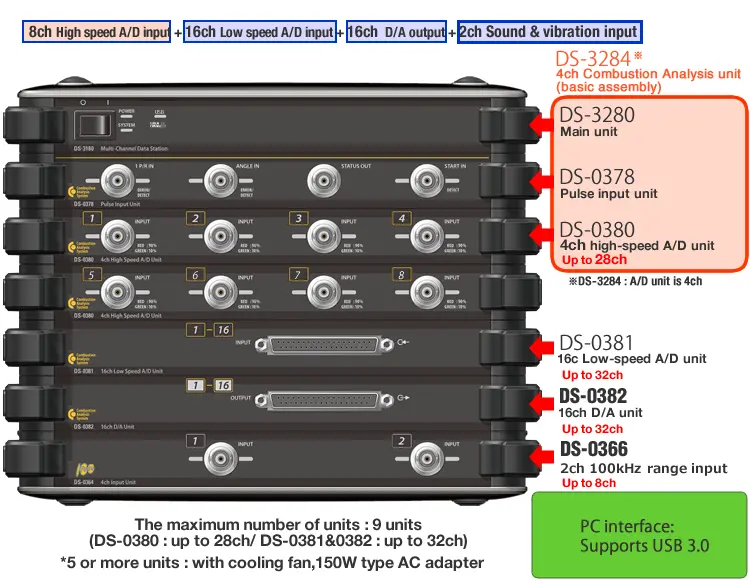

Hardware configurations

Hardware specification

DS-0380 4ch Combustion Analysis High-speed A/D Unit

| The number of input channels | 4 ch / unit (max.28 ch, up to 5 unit) |

|---|---|

| Input method | Single-ended |

| Isolation | Isolated between units (COM signal of 4 inputs in an unit is shared.) |

| Terminal type | BNC terminal |

| Input impedance | 1 MΩ |

| Coupling | DC coupling |

| Input voltage range | ±0.1/0.2/0.5/1.0/2.0/5.0/10.0 V |

| Level monitor LED | -20 dB (green), -0.915 dB (red) |

| Offset voltage | ± ±100 % voltage range F.S. (error: ±1.0 % or less) |

| A/D resolution | 16-bit successive conversion type |

| Sampling frequency | Max. 1 MHz |

| Data memory | 56 MB/ch |

| Weight | Approx. 900 g |

DS-0378 Combustion Analysis Pulse Input Unit

| Pulse input section | |

|---|---|

| Input impedance | 100 kΩ |

| Input method | Single-ended |

| Isolation | Non-isolated |

| Terminal type | BNC terminal |

| Coupling | AC or DC coupling |

| Input voltage range | ±10 V |

| Absolute maximum input range | ±45 V |

| Minimum input voltage | 1.0 Vp-p |

| Monitor LED | Normal signal (green) / abnormal signal (red) |

| Trigger level | ±10 V, setup resolution 10-bit |

| Trigger slope | + (rising), − (falling) |

| Isolation | |

| Isolation | Isolated between 「1 P/R input, angle pulse input」「External start input」 and 「Status output」 (Common of 1 P/R input and angle pulse input is shared.) |

| Input format | TTL or non-voltage contact signal |

| Internal pull-up resistor | 100 kΩ connected to internal +5 V |

| Minimum pulse width | 10 ms |

| Status output | |

| Output format | TTL |

| External start function | BNC input terminal to start

measurement by TTL level or non-voltage contact signal Detection slope: Rising or falling |

| Weight | Approx. 800 g |

DS-0381 16ch Combustion Analysis Low-speed A/D Unit

| The number of input channels | 16 ch / unit (max. 32 ch, up to 2 units) |

|---|---|

| Input method | Single-ended |

| Isolation | Non-isolated |

| Terminal shape | D-SUB 37-pin |

| Input impedance | 1 MΩ |

| Coupling | DC coupling |

| Voltage range | ±1.0/2.0/5.0/10.0 V |

| A/D resolution | 16 bit |

| Sampling angle | 45 ° |

| Sampling method | Multiplex method |

| Weight | Approx. 800 g |

| Accessory | BNC connector box, signal cable (1.5 m) |

DS-0382 16ch Combustion Analysis D/A Unit

The DS-0382 enables output of combustion analysis calculation data (Pi, Pmax etc.) as analog data. A single unit consists of 16 channels and is extendable for up to 32 channels.

| The number of output channels | 16 ch / unit (max. 32 ch, 2 units) |

|---|---|

| Output method | Single-ended (GND common to each channel) |

| Isolation | Non-isolated |

| Terminal shape | D-SUB 37-pin (with external BNC connector box ) |

| Output impedance | 1 Ω or less |

| Load impedance | 10 kΩ or more |

| Maximum output current | ±1 mA |

| Output coupling | DC coupling |

| Output voltage range | ±10.0 V |

| D/A resolution | 14-bit |

| Rising time | 100 µs or less (time to settle within 10 % to 90 % of variation from −10 V to +10 V) |

| Weight | Approx. 800 g |

| Accessory | BNC connector box, signal cable (1.5 m) |

DS-3284 Combustion Analysis Main Unit

| AC power voltage | 100 to 240 VAC |

|---|---|

| DC power voltage | 10.5 to 16.5 V*1 |

| Power consumption | Approx. 27 to 67 W*2 |

| Operating temperature range | 0 to +40 °C(non-isolated) |

| Storage temperature range | −10 to +60 °C |

| CE marking | Conformed |

| The number of maximum units | 9 units |

| PC interface | USB 3.0 interface |

| Outer dimensions | 257 (W)×104 to 344 (H)×182 (D) mm*2 |

| Weight | Approx. 3.1 to 8.5 kg*2 |

Note: 150W type AC adapter is required in 5 or more units. (Cooling fan is attached.)

*1:10.5 to 16.5 V in 4 units

*2:The value will be changed depending on the number of units.

Operating environment

| OS | Microsoft® Windows® 10 Pro Microsoft® Windows® 11 Pro Please refer to the software operating environment (WindowsⓇ) for the version details. |

|---|---|

| CPU | Intel® CoreTM i7 or higher grade, and 8th Generation or later generation |

| Memory | Minimum 16 GB (for high speed 12CH or more, 32 GB recommended) |

| Drive | DVD optical drive (required at installation) |

| Interface | USB type A USB 3.0 × 3 ports or more (When using EX-0436, LAN terminal is required.) |

| Display | Full HD 1920 X 1080 |

* Microsoft® Windows® are registered trademarks of Microsoft Corporation in the United States and other countries.

Other product names and model names are trademarks or registered trademarks of each individual company. The copyrights are reserved by each individual company.

Crank angle detector (option)

- CP-5110B Fiber optic crank angle detector + Slit disk (CP-5120/5130) + Crank angle amplifier (CA-6000B)

- CP-5730 Fiber optic crank angle detector ( Slit disk and detector all in one type) + Crank angle amplifier (CA-6000B)

| Crank angle detector CP-5110B (Slit disk is required.) |

Crank angle detector CP-5730 (Slit disk is included.) |

Crank angle amplifier CA-6000B |

|---|---|---|

|

|

|

Related information

Revised: 2025/02/14