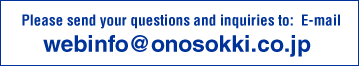

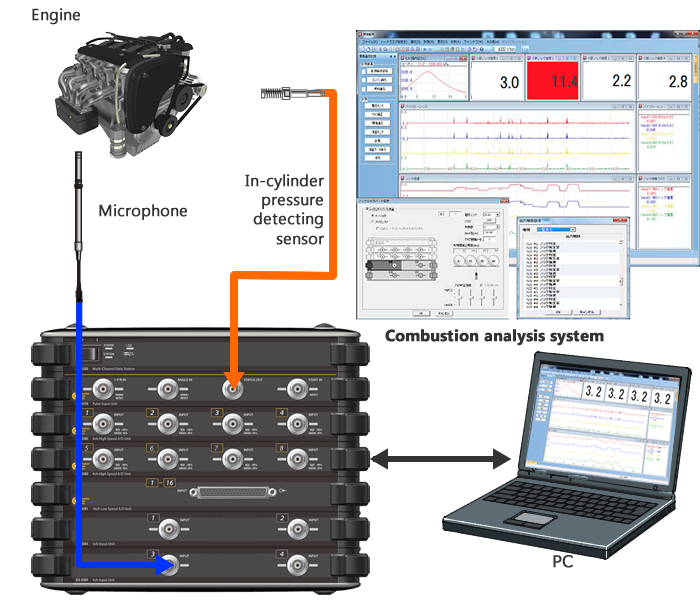

DS-3000 series will assist the R&D on increasing fuel efficiency with smaller engines.

With the ongoing research and development for improving combustion technologies (HCCI, EGR, etc.), new power sources (HEV and PHEV) and new fuels (biodiesel and natural gas) , development of more fuel-efficient and smaller engines are demanded. The DS-3000 series Engine Combustion Analyzer meets such growing expectations with the new, more powerful hardware.

Functions related to cooperative measurement with actual cars and operation boards of test bench etc. have been enhanced.

DS-0328: Combustion Analysis Software<enhanced>

•Function analyzing every each cylinder

•Filter processing function

DS-0336: Combustion Data Link Function<improved>

•Combustion link function

(Item for combustion specifications was increased which can be set remotely, such as from the control panel of the test bench and higher control system. )

(Item for combustion specifications was increased which can be set remotely, such as from the control panel of the test bench and higher control system.)

DS-0339: Knocking Expert Function<newly added>

•Automatic calibration function using CAN communication

DS-0360: Encoderless Measurement Function<newly added>

•Measurement function using long-teeth gear signal

(The measurement function using a long gear signal which is input/output to ECU for the controlling rotation of a two-wheel engine etc.)

DS-0383: CAN Measurement Function<newly added>

•Test output & database file output

(The function to output the combustion calculation result for each cycle to the CAN database file)

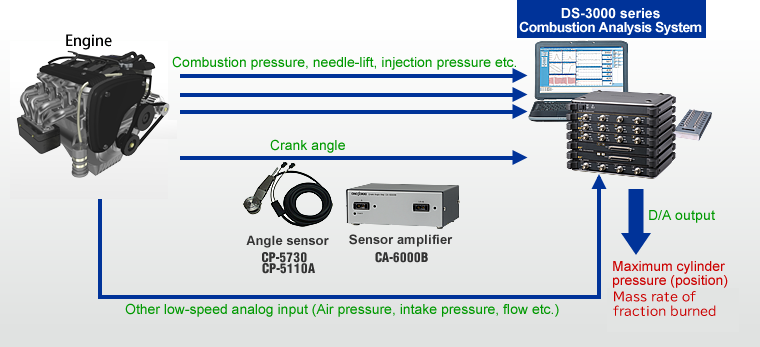

Major function of the DS-0328 standard software

Physical qty. & judging process-Analysis function for each cylinder

Internal cylinder pressure sensor information acquisition functionBasic software of combustion analysis including monitor function, measurement/calculation, and data storage.

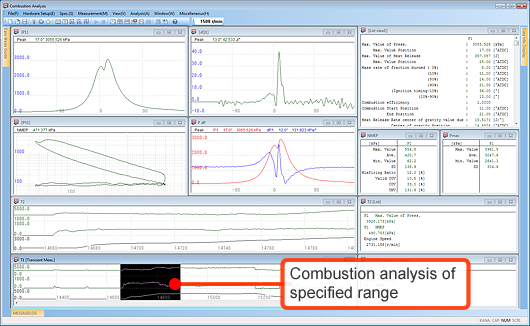

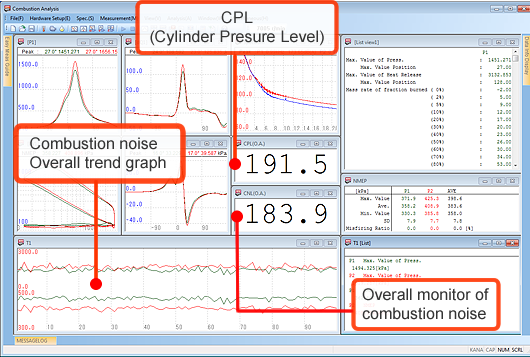

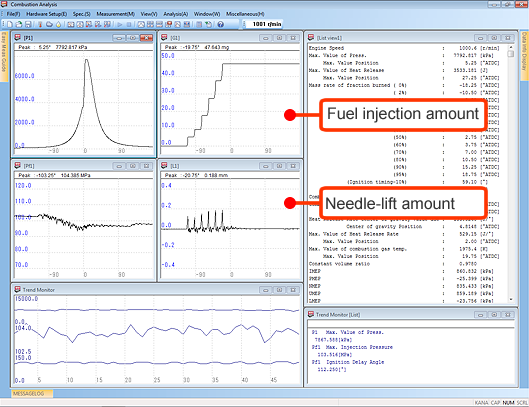

The analysis result of a channel can be displayed

in various types of graphs and lists on one window. Also, combination display of real-time trend data and intermittent trend data is available in the trend window. The following is an example of overlaying display, list display, trend display etc.

Basic combustion analysis can be performed easily just to click the

buttons in order from the front on the simple operation measurement

panel,

• The number of input pulses : 180/360/720/1800/3600 P/R

• Angular sampling resolution : 0.05/0.1/0.25/0.5/1.0°

• Input rotation range

| 0.05°: | 10 to 8,000 r/min |

| 0.1°: | 10 to 16,000 r/min |

| 0.25/0.5/1.0°: | 10 to 25,000 r/min |

• Setup specification: Environmental specification, engine specification, and fuel specification (composition weight ratio, element ratio)

All cylinder TDC auto correction function

Test mode: Manual, auto storage, starting test

| Low-speed A/D input function |

| Environmental specification or other data can be measured by adding the "DS-0381 16ch Low-speed A/D input unit for combustion". The data is measured at every 45° to perform averaging processing. That is a representative value of the cycle. |

| Analog output function |

| Combustion calculation value is outputted as a voltage signal while operating calculation monitor by adding the "DS-0382 16ch D/A output unit for combustion". |

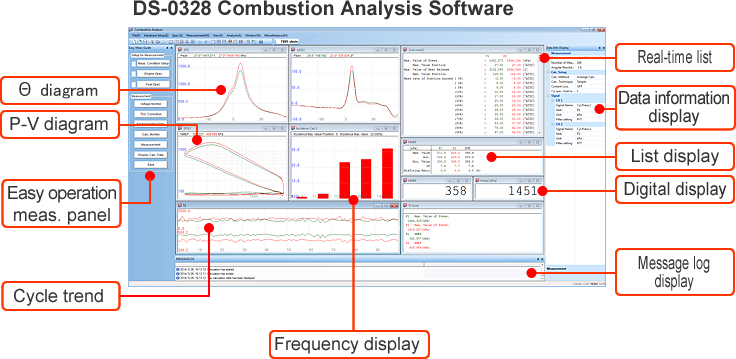

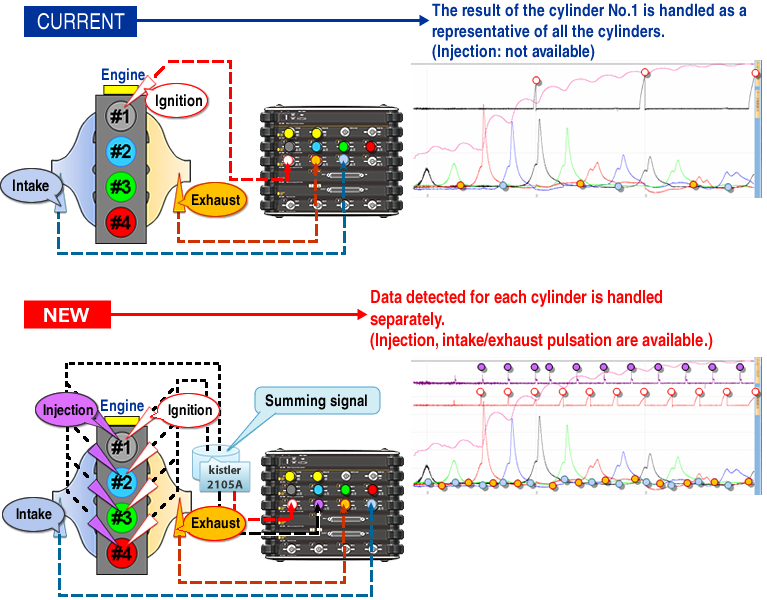

Physical qty. & judging process –Analysis function for each cylinder (DS-0328 standard software)

This function can analyze the combustion state for each cylinder by using the ignition signal / fuel injection signal / intake exhaust pulsation signal outputted from the ECU for combustion control. Effective function used for multiple cylinder measurement, including measurement by actual vehicles or measurement on the test bench.

Because analysis data can be linked to each cylinder, you can organize large number of data without mistake, even if analysis items are increased significantly and troublesome work is also increased.

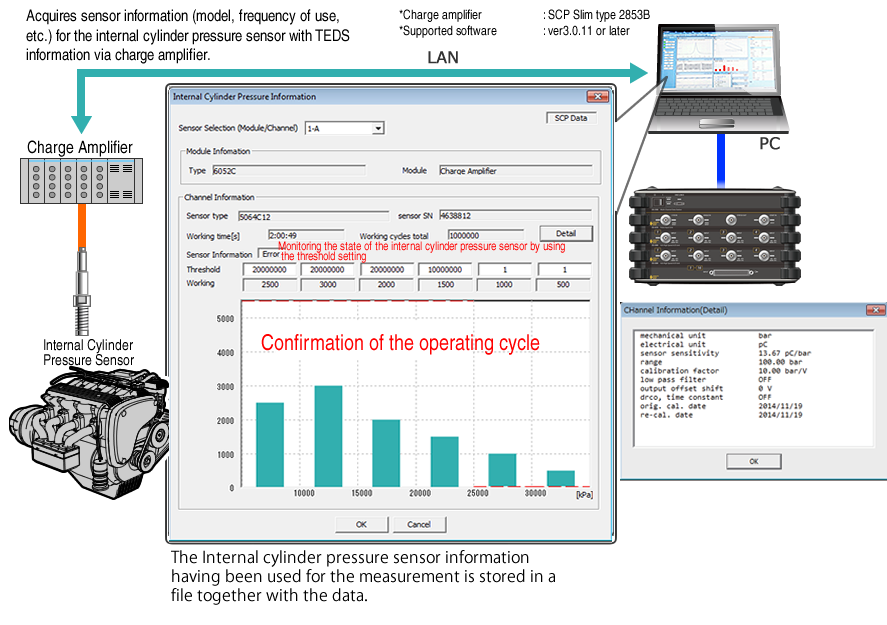

Internal cylinder pressure sensor information acquisition function

Internal Cylinder Pressure Sensor Information Acquisition Function

This function enables acquiring the product related information, such as operating time and sensor specification, from the internal cylinder pressure sensor incorporating the TEDS function to check the usage status. You can use the information as a guideline for replacement timing or additional purchase of the sensor.

(This function supports only for the internal cylinder pressure sensor with TEDS by Kistler Instrument Corp.)

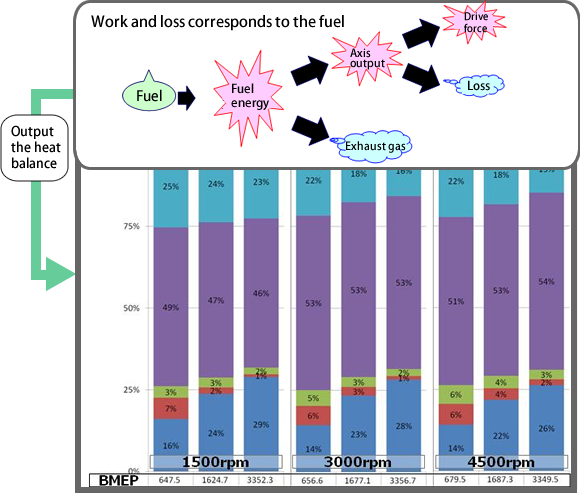

Heat balance calculation function

This function can calculate each work and loss corresponds to the fuel which is inserted to the combustion chamber. This function can output heat balance which should have been calculated manually.

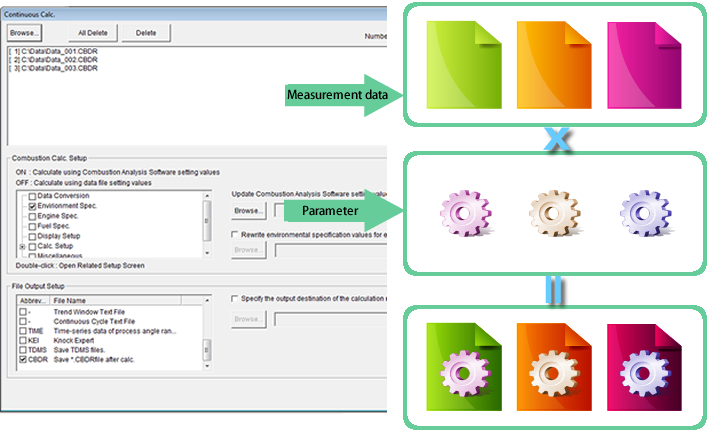

Continuous calculation function

You can calculate multiple data files at all while changing parameter settings necessary for the calculation.

The work efficiency is improved by recalculating a plurality of measurement data files having different conditions collectively.

Optional function and measurement unit

| Optional function | DS-3000 (DS-0380) |

DS-2000 B version (DS-0280B) |

DS-2000 A version (DS-0280A) |

DS-2000 (DS-0280) |

|---|---|---|---|---|

| DS-0328T Transient combustion analysis function

|

○ | ○ | ○ | ○ |

| DS-0329 Knocking analysis function | ○ | ○ | ○ | ○ |

| DS-0335 SYNC measurement function | ○ | × | × | × |

| DS-0336 Combustion data link function | ○ | ○ | ○ | ○ |

| DS-0337 Combustion noise analysis function | ○ | ○ | ○ | ○ |

| DS-0339 Knock expert function | ○ | × | × | × |

| DS-0349 Crank angle pulse period measurement function | ○ | ○ | ○ | × |

| DS-0358 Multi-stage injection calculation software function | ○ | ○ | ○ | ○ |

| DS-0360 Encoderless measurement function | ○ | ○*1 | ○*1 | × |

| DS-0361 Torque fluctuation analysis function | ○ | ○ | ○ | × |

| DS-0363 Calculation customization function | ○ | ○ | ○ | ○ |

| DS-0365 INCA Link function | ○ | × | × | × |

| DS-0383 CAN measurement function*2 | ○ | × | × | × |

*1: When the DS-2000 series is used as measurement unit, the accuracy decreases than the time when the DS-3000 series is used.

*2: Hardware option (VN1610 CAN interface) is required to use this function.

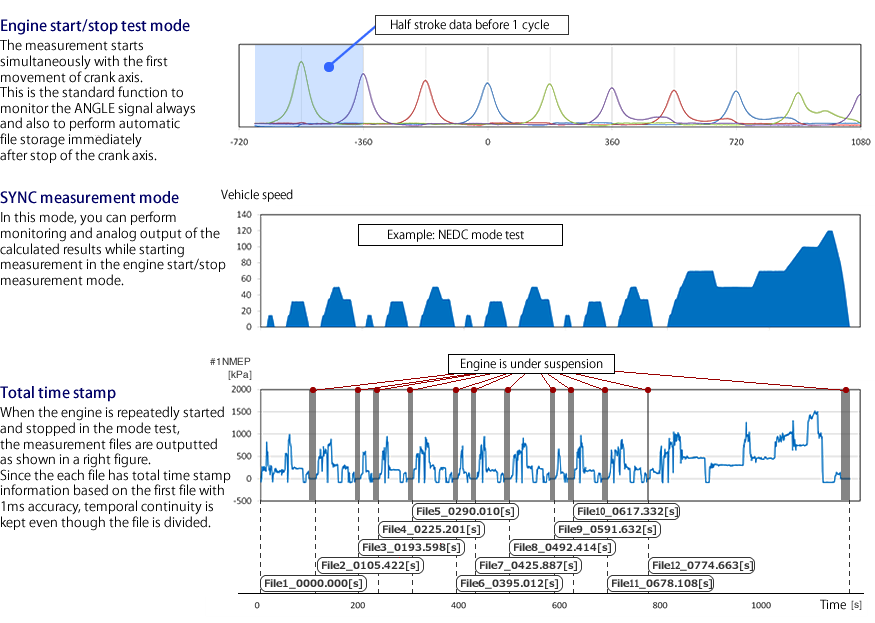

DS-0328T Transient combustion analysis function

This application software is designed for multiple cycle (extended) measurement such as transient mode tests (JC08 and JE05). Efficient analysis can be achieved by processing only the areas specified by cycle trends in transient measurement.

| Angular Resolution[ °] | The maximum number of cycles | Recording time (1,800 r/min average) |

|---|---|---|

| 0.05 | 30,000 | Approx. 30 min |

| 0.1 | 60,000 | Approx. 60 min |

| 0.25 | 100,000 | Approx. 110 min |

| 0.5 | 100,000 | Approx. 110 min |

| 1.0 | 100,000 | Approx. 110 min |

* The above is the value of 4ch measurement.

The value will be changed depending on the content of calculation

processing or the number of channels.

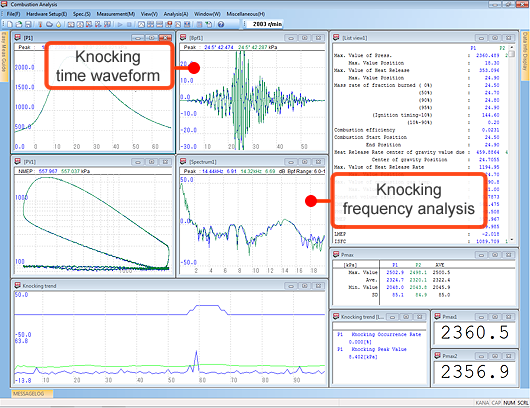

DS-0329 Knocking analysis function

Engine knocking is detected by monitoring for disturbance in cylinder pressure signals. Real-time calculations for knocking values and occurrence rates are available. Calculation of knocking and thresholds are monitored and displayed in trend and numerical forms.

DS-0335 SYNC measurement function

The DS-2000 series/ DS-3000 series combustion analysis system has supported the test of an engine which is included in a vehicle with idling stop system and hybrid system for many years by the engine start/stop test mode. In recent year, the mode tests (JC08 mode and NEDC mode) to nearly completed vehicles are increasing for performance evaluation.

Selecting SYNC measurement mode as the measurement mode enables users to save measurement results obtained over the integration time from measurement start to end.

* DS-0329 Knocking analysis function cannot be used with this function at the same time.

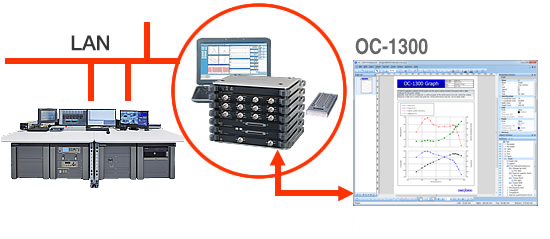

DS-0336 Combustion Link function

Data communication through TCP/IP sockets enables the following processing. For example, synchronized recording of performance and combustion analysis data can be achieved by linking up to an engine bench.

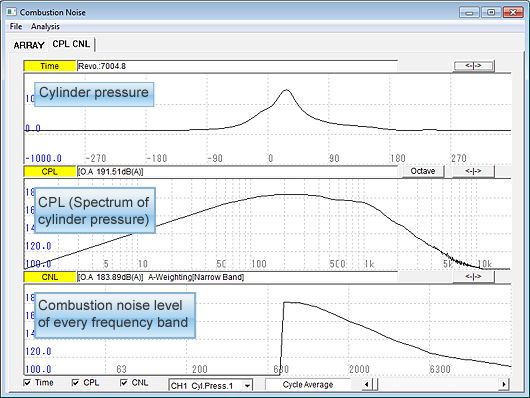

DS-0337 Combustion noise analysis function

CPL (Cylinder Pressure Level) is calculated based on cylinder pressure while CNL (Combustion Noise Level) is calculated based on the magnitude of engine structural attenuation. Calculation monitoring, trend display and numerical display are available. Angle sampling that uses the same method as combustion analysis makes it possible to analyze combustion noise.

DS-0339 Knock expert function

Combustion pressure signal and sound pressure signal is used.

• Measures sound pressure level in one microphone and detects up to 4 cylinders of knocking.

• Detection sensitivity is selectable from 5 levels depending on the sound pressure level.

• It is possible to change detection sensitivity, judgment level and then recalculate after measurement.

• Knocking level is judged to the user-specified knocking index (trace/light/heavy) by using in combination the Knocking level index of DS-0339 and the frequency processing function of the DS-0328.

Added a function to perform calibration measurement automatically using CAN communication command.

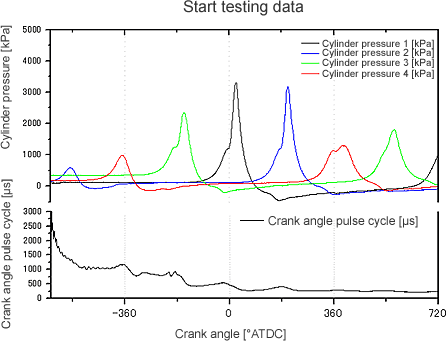

DS-0349 Crank angle pulse cycle measurement function

This function measures crank angle pulse cycle and performs calculations. The above graph is an example to show the start testing data using absolute angle text file. (Start measurement function is provided as standard.)

DS-0358 Multi-stage injection calculation function

Measurement items related to fuel injection and combustion can be calculated. (Up to 10 stages)

Calculation items to each injection

Max. injection pressure, position of max. value, valve-opening pressure, fuel

injection start /stop position, center of gravity position for rate of fuel

injection, center of gravity position, ignition delay angle

Calculation items to each combustion

Center of gravity position for rate of heat release, center of gravity position,

combustion start / stop position, cylinder pressure and gas temperature in a

combustion chamber at combustion start position

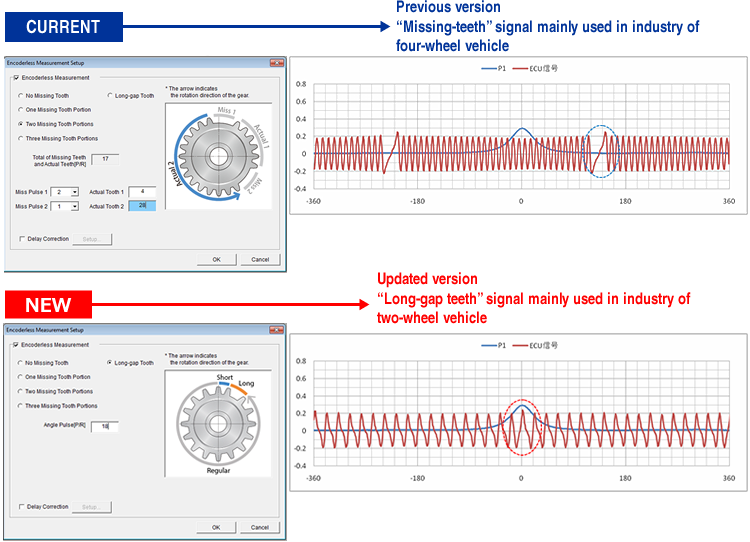

DS-0360 Encoderless measurement function

A new algorithm based on real-time conversion into small number pulse (8 to 360 P/R) angle signals offers encoder-less stable measurements even during acceleration and deceleration.

An encoder for crank angle detection is not required. Measurements are based on small number pulses such as crank angle signals for ECU (missing teeth pulse signals) and ring gears. Delay correction is also available.

• Angle pulse: 8 to 360 P/R

• Missing teeth: 0 to 4 P / location (1 P/R needed for 0 P/location)

NOTE: Please check carefully the specifications (magnitude and shape) of our

angle pulse signal products before purchase.

Detection of long-teeth pulses is now supported and the range of detectable engines is increased.

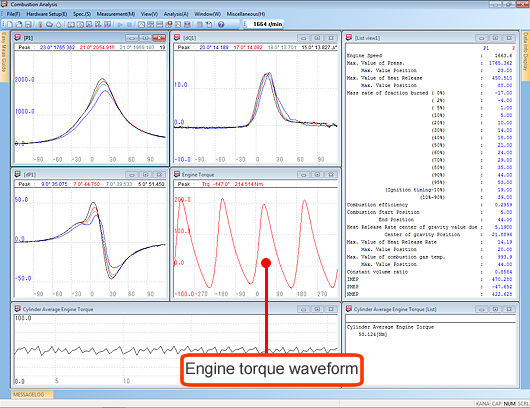

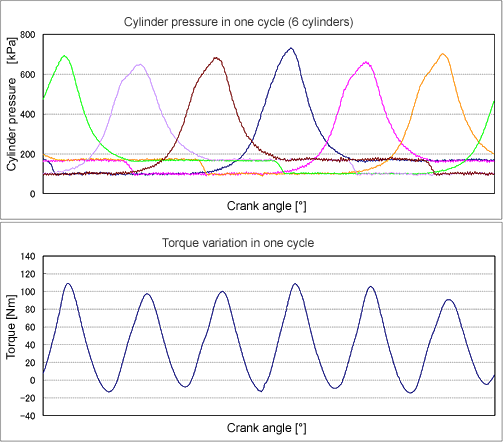

DS-0361 Torque fluctuation analysis

(The above graphs have been created using absolute angle text files (in abs format).)

By using the cylinder pressure for each cylinder, friction/inertial- adjusted engine torque data is calculated.

DS-0363 Customizing calculation function

Computation formulas can easily be created as required as part of basic combustion analysis functions.

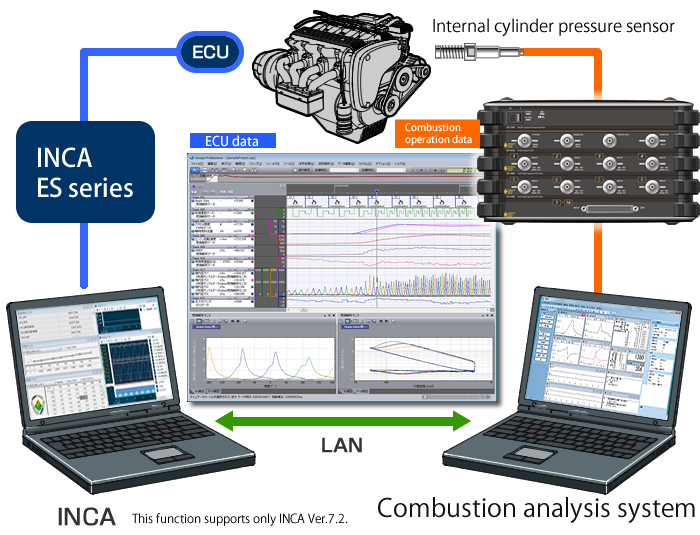

DS-0365 INCA Link function

This function enables link measurement with ECU calibration tool INCA made by ETAS.

ECU performance data and combustion analysis data can be measured in time synchronization.

·Data communication via LAN (TCP/IP socket)

·By linking to the engine bench, ECU performance data and the following combustion data can be measured synchronously.

It is the best function for efficient engine calibration.(*Measureable data: internal cylinder pressure, rate of increase of internal cylinder pressure, combustion weight ratio position, rate of heat release, IMEP, NMEP, etc. )

·Measured data can be converted to MDF file format and saved via INCA.

Since it is applicable to ASAM file format, it is easy to manage and standardize other instrument data.

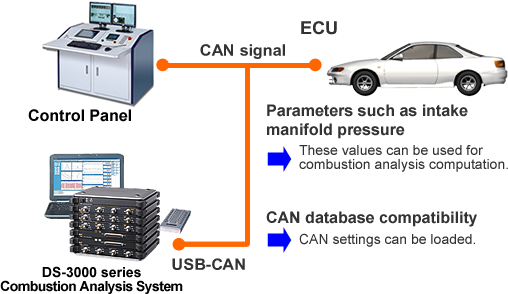

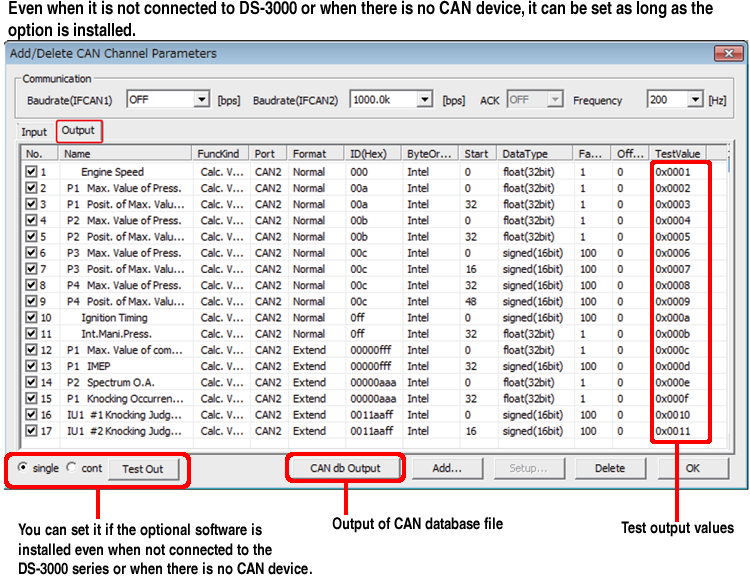

DS-0383 CAN measurement function

Cycle-by-cycle analysis can be made by synchronizing combustion analysis data with CAN data, which is becoming increasingly important as the basis for automotive control.

Test output and database file output are now ![]()

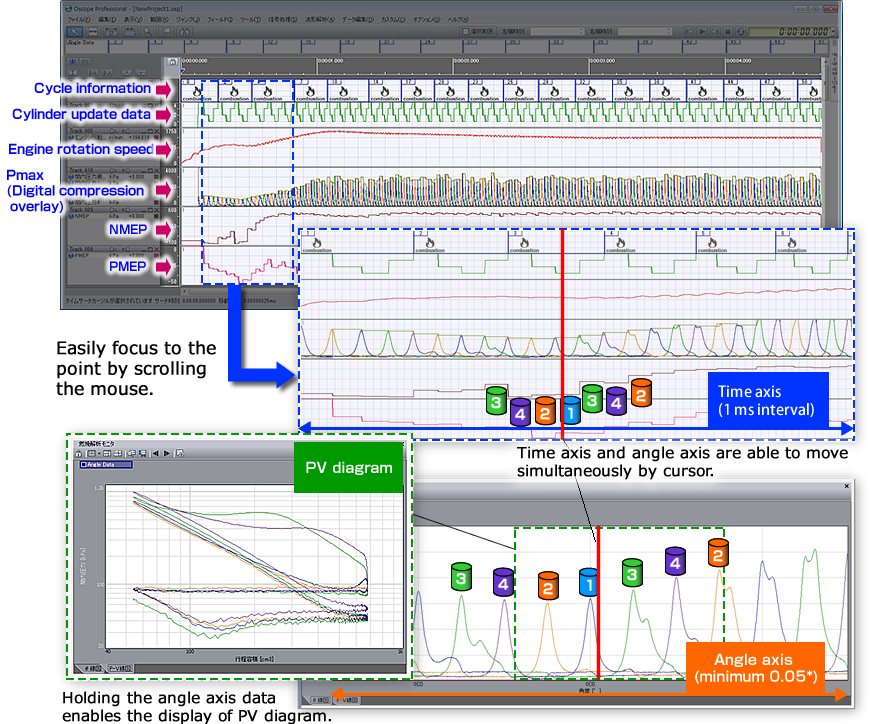

Use with the OS-2000 series (Time-series data analysis software)

The combustion analysis software is now available to output the TDMS file which is applicable to ASAM file. The following data are stored in the TDMS file: actual measured angle axis data including in-cylinder pressure signal, TDC calculation data which is used to check the time difference of combustion calculation result (NMEP, combustion weight ratio position, etc.).

By importing the TDMS file to the OS-2000 series, the phenomenon of angle axis data is analyzed while checking the time axis difference of the combustion calculation result in OS-2000 series.

The OS-2000 can import the performance data file (.thd) measured by FAMS and ECU data (.mf4) measured by INCA made by ETAS corporation. Those data can be matched and analyzed with the combustion analysis data.

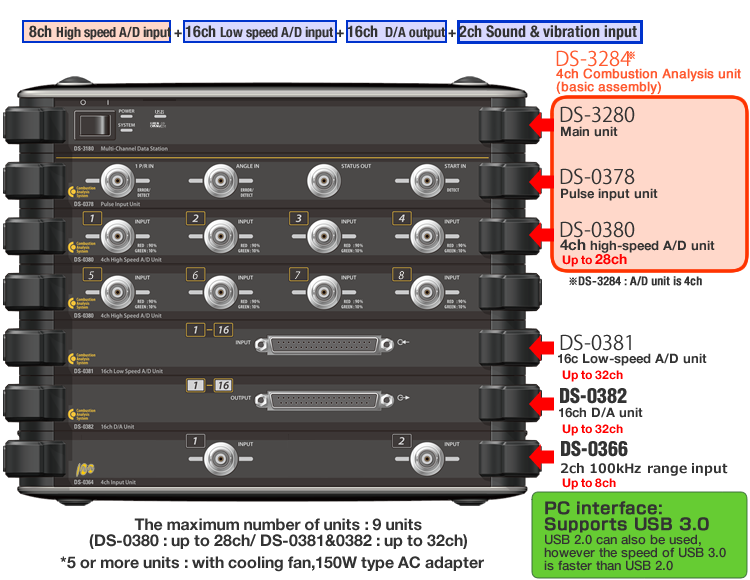

Optional hardware list

| Model name | Product name |

|---|---|

| DS-3284 | Combustion Analysis Main Unit |

| DS-0380 | 4ch Combustion Analysis High-speed A/D Unit |

| DS-0378 | Combustion Analysis Pulse Input Unit |

| DS-0381 | 16ch Combustion Analysis Low-speed A/D Unit |

| DS-0382 | 16ch Combustion Analysis D/A Unit |

Hardware specification

DS-0380 4ch Combustion Analysis High-speed A/D Unit

| The number of input channels | 4 ch / unit (max.28 ch, up to 5 unit) |

|---|---|

| Input method | Single-ended |

| Isolation | Isolated between units (COM signal of 4 inputs in an unit is shared.) |

| Terminal type | BNC terminal |

| Input impedance | 1 MΩ |

| Coupling | DC coupling |

| Input voltage range | ±0.1/0.2/0.5/1.0/2.0/5.0/10.0 V |

| Level monitor LED | -20 dB (green), -0.915 dB (red) |

| Offset voltage | ±100 % voltage range F.S. (error: ±1.0 % or less) |

| A/D resolution | 16-bit successive conversion type |

| Sampling frequency | Max. 1 MHz |

| Data memory | 56 MB/ch |

| Weight | Approx. 900 g |

DS-0378 Combustion Analysis Pulse Input Unit

| Pulse input section | |

|---|---|

| Input impedance | 100 kΩ |

| Input method | Single-ended |

| Isolation | Non-isolated |

| Terminal type | BNC terminal |

| Coupling | AC or DC coupling |

| Input voltage range | ±10 V |

| Absolute maximum input range | ±45 V |

| Minimum input voltage | 1.0 Vp-p |

| Monitor LED | Normal signal (green) / abnormal signal (red) |

| Trigger level | ±10 V, setup resolution 10-bit |

| Trigger slope | + (rising), − (falling) |

| Isolation | |

| Isolation | Isolated between 「1 P/R input, angle pulse input」「External start input」 and 「Status output」 (Common of 1 P/R input and angle pulse input is shared.) |

| External start input | |

| Input format | TTL or non-voltage contact signal |

| Internal pull-up resistor | 100 kΩ connected to internal +5 V |

| Minimum pulse width | 10 ms |

| Status output | |

| Output format | TTL |

| External start function | BNC input terminal to start

measurement by TTL level or non-voltage contact signal Detection slope: Rising or falling |

| Weight | Approx. 800 g |

DS-0381 16ch Combustion Analysis Low-speed A/D Unit

| The number of input channels | 16 ch / unit (max. 32 ch, up to 2 units) |

|---|---|

| Input method | Single-ended |

| Isolation | Non-isolated |

| Terminal shape | D-SUB 37-pin |

| Input impedance | 1 MΩ |

| Coupling | DC coupling |

| Voltage range | ±1.0/2.0/5.0/10.0 V |

| A/D resolution | 16 bit |

| Sampling angle | 45 ° |

| Sampling method | Multiplex method |

| Weight | Approx. 800 g |

| Accessory | BNC connector box, signal cable (1.5 m) |

DS-0382 16ch Combustion Analysis D/A Unit

The DS-0382 enables output of combustion analysis calculation data (Pi, Pmax etc.) as analog data. A single unit consists of 16 channels and is extendable for up to 32 channels.

| The number of output channels | 16 ch / unit (max. 32 ch, 2 units) |

|---|---|

| Output method | Single-ended (GND common to each channel) |

| Isolation | Non-isolated |

| Terminal shape | D-SUB 37-pin (with external BNC connector box ) |

| Output impedance | 1 Ω or less |

| Load impedance | 10 kΩ or more |

| Maximum output current | ±1 mA |

| Output coupling | DC coupling |

| Output voltage range | ±10.0 V |

| D/A resolution | 14-bit |

| Rising time | 100 µs or less (time to settle within 10 % to 90 % of variation from −10 V to +10 V) |

| Weight | Approx. 800 g |

| Accessory | BNC connector box, signal cable (1.5 m) |

DS-3284 Combustion Analysis Main Unit

| AC power voltage | 100 to 240 VAC |

|---|---|

| DC power voltage | 10.5 to 16.5 V*1 |

| Power consumption | Approx. 27 to 67 W*2 |

| Operating temperature range | 0 to +40 °C(non-isolated) |

| Storage temperature range | −10 to +60 °C |

| CE marking | Conformed |

| The number of maximum units | 9 units |

| PC interface | USB 3.0 interface (USB 2.0 can also be used, however the speed of USB 3.0 is faster than USB 2.0.) |

| Outer dimensions | 257 (W)×104 to 344 (H)×182 (D) mm*2 |

| Weight | Approx. 3.1 to 8.5 kg*2 |

Note: 150W type AC adapter is required in 5 or more units. (Cooling fan is attached.)

*1:10.5 to 16.5 V in 4 units

*2:The value will be changed depending on the number of units.

| CPU | Intel® CoreTM i5 or more |

|---|---|

| Memory capacity | 4 GB or more |

| Interface | USB 3.0 interface (USB 2.0 can also be used, however the speed of USB 3.0 is faster than USB 2.0.) |

| OS | Microsoft® Windows® 7 Ultimate/Professional (64/32-bit version) Microsoft® Windows® 10 Professional (64/32-bit version) Microsoft.NET Framework 3.5 or later is supported. |

* Microsoft® Windows® are registered trademarks of Microsoft Corporation in the United States and other countries.

Other product names and model names are trademarks or registered trademarks of each individual company. The copyrights are reserved by each individual company.

Crank angle detector (option)

Examples

CP-5110B Fiber optic crank angle detector + Slit disk (CP-5120/5130) + Crank angle amplifier (CA-6000B)

CP-5730 Fiber optic crank angle detector ( Slit disk and detector all in one type) + Crank angle amplifier (CA-6000B)

| Crank angle detector CP-5110B (Slit disk is required.) |

Crank angle detector CP-5730 (Slit disk is included.) |

Crank angle amplifier CA-6000B |

|---|---|---|

• Optical fiber offering high resistance to noise • Improved optical system offering reliable detection • Compact and lightweight, so can be used even on engines with heavy vibration • Designed to match your settings • No bearings, therefore light rotational load |

• Optical fiber offering high resistance to noise • Improved optical system offering reliable detection • Weight reduction of the rotating parts and structural improvement of the rotation stops have increased the vibration resistance • High-speed bearings offering smooth operation |

• Receives signals (Phase A: angle signals, 1 P/R: reference signals) from a crank angle detector; Sends out TTL level or analog signals • Crank angle detector sensitivity matching through an external volume • High noise resistance corresponding to the CE marking requirements • Adaptable to different crank angle detectors with the flick of a switch |

Revised:2020/4/14