21 May 2025

Supporting the Transfer of Technical Skills in Japanese Manufacturing

The New Portable Vibration Meter VW-3100

Product launch scheduled for August 2025

Ono Sokki Co., Ltd. will unveil its new product, the Portable Vibration Meter VW-3100, on the 21st of May 2025. The product is scheduled to launch in August 2025. This all-in-one vibration meter performs “listening,” “measuring,” and “evaluating” in maintenance and inspection tasks.

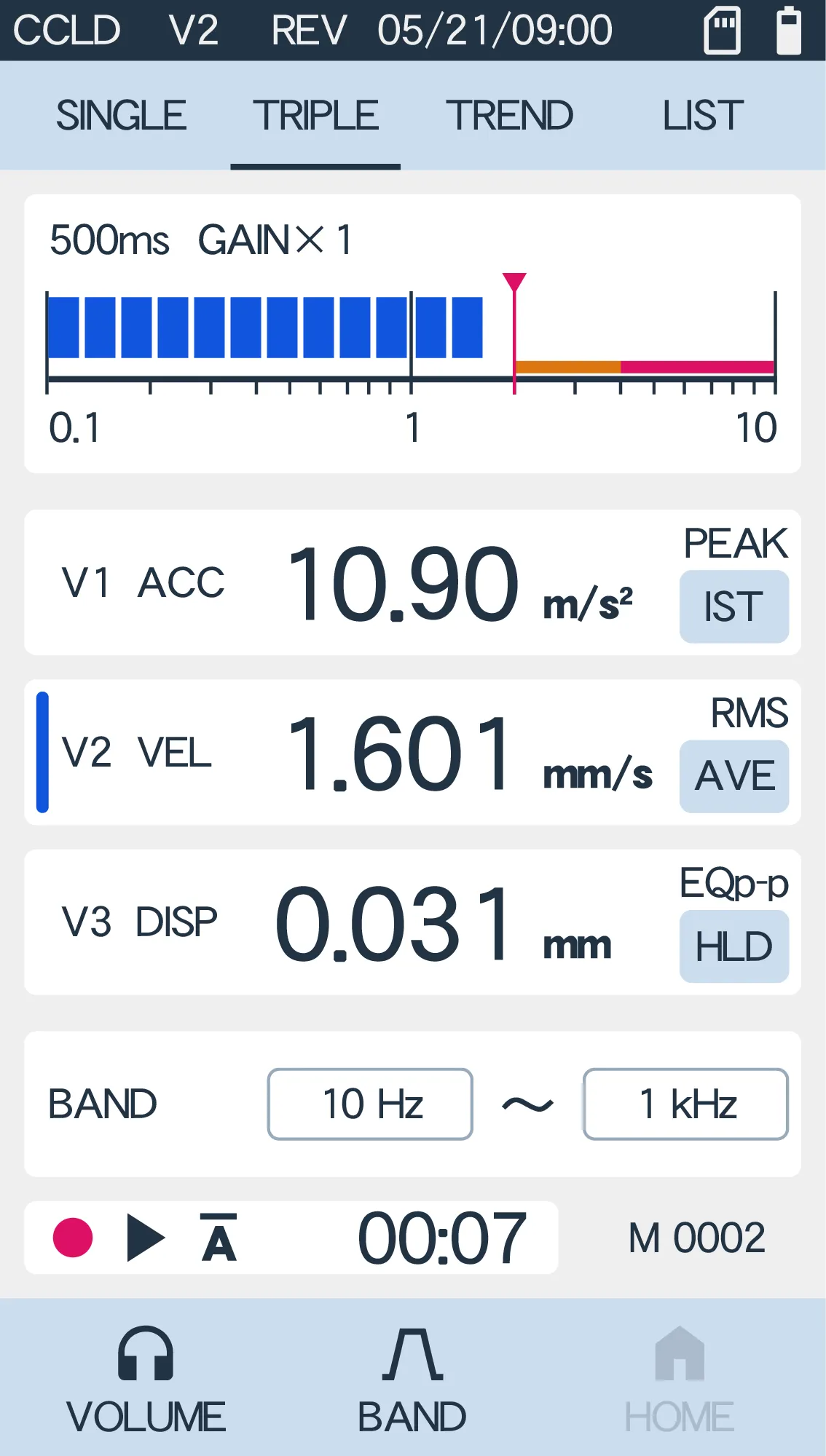

Portable Vibration Meter VW-3100

Ono Sokki is a Japanese manufacturer founded in 1954, specializing in electronic measuring

instruments and engineering services. We provide advanced measurement solutions for R&D and production across a wide range of industries, including automotive, construction machinery, food processing, and medical diagnostics. With over 70 years of experience, we are committed to delivering precision, reliability, and innovation worldwide.

Equipment diagnosis by vibration measurement has long been used to monitor the condition of rotating machinery. Even now, abnormality detection on-site still relies on the intuition and experience of worker using an auscultation rod. However, there are challenges such as variability due to individual differences and the difficulty of passing down know-how.

This product uses our unique signal processing technology to extract and quantify abnormal components, thereby increasing the detection accuracy of abnormal signs. This enables a shift from diagnosis relying on experience to data-based methods, and is expected to be used as a tool to improve the accuracy of decisions in the design and maintenance departments and to support the transfer of know-how.

4 Key Highlights of the New VW-3100 Portable Vibration Meter

- Simultaneous measurement and display of 3 physical quantities of vibration in the V3 Bands, which enables to improve work efficiency by accurately identifying abnormalities

- Listening function with variable band-pass filters for anomaly detection and skill transfer

- Simultaneous data recording during inspections (ORF/WAV format)*, facilitating advanced diagnostics through post-analysis software like the O-Solution (https://www.onosokki.co.jp/English/hp_e/products/keisoku/data/osolution.htm)

- A wide range of optional functions to support on-site measurements and evaluations.

*Recording is optional function.

Target Markets and Key Applications

- Equipment diagnostics for rotating machinery in manufacturing facilities across various industries

- Pass/fail judgment in production and inspection lines for motors, compressors, and other components in the automotive and home appliance industries

Features

Simultaneous measurement and display of 3 physical quantities of vibration in the V3 Bands

Ono Sokki's unique "V3 Band" function uses three variable band-pass filters (BPFs) to enable simultaneous measurement of different frequency bands. You can select a physical quantity (acceleration, velocity, or displacement) for each band, and simultaneously calculate effective (rms) values, peak values, and other values. With the "V3 Band", the frequency band for each physical quantity can be flexibly set according to the abnormal vibration. This allows for more accurate detection of abnormal sounds and quantitative evaluation.

Listening function using a variable band-pass filter

This product converts the vibration signals acquired by the sensor into sounds and listen to them. It is effective as an alternative tool to an auscultation rod, and also useful for identifying abnormal sounds on site, sharing information between operators and assisting in the transmission of technology.

Recording/Comparison function (option:VW-0320)

Recording (ORF/WAV) is possible immediately while measuring and inspecting. The data can be taken back to the office for detailed analysis and listening with post-analysis software such as the O-Solution, leading to a precise diagnosis. The three recorded data can be switched and compared with the vibration sounds measured on site, making it easier to determine whether or not there are any abnormalities.

A wide range of optional functions to support on-site measurements and evaluations

-

Equlizing Function VW-0310

The amplitude of vibration sound can be adjusted in increments of 1/1 octave. It enables to reproduce how experienced workers listen and pass on their sense of critical points. -

Filter Expansion Function VW-0330

In addition to the standard band-pass filter, more detailed frequencies can be selected. -

ISO Evaluation and Judgment Function VW-0340

The VW-3100 supports the evaluation of vibration severity, an important index of the condition of rotating machinery. It is equipped with filters compliant with ISO 2954:2012, and enables A/B/C/D-level assessments in accordance with ISO 20816-3:2022 and ISO 20816-1:2016. In addition, custom threshold values can be set based on the characteristics of the machinery being monitored.

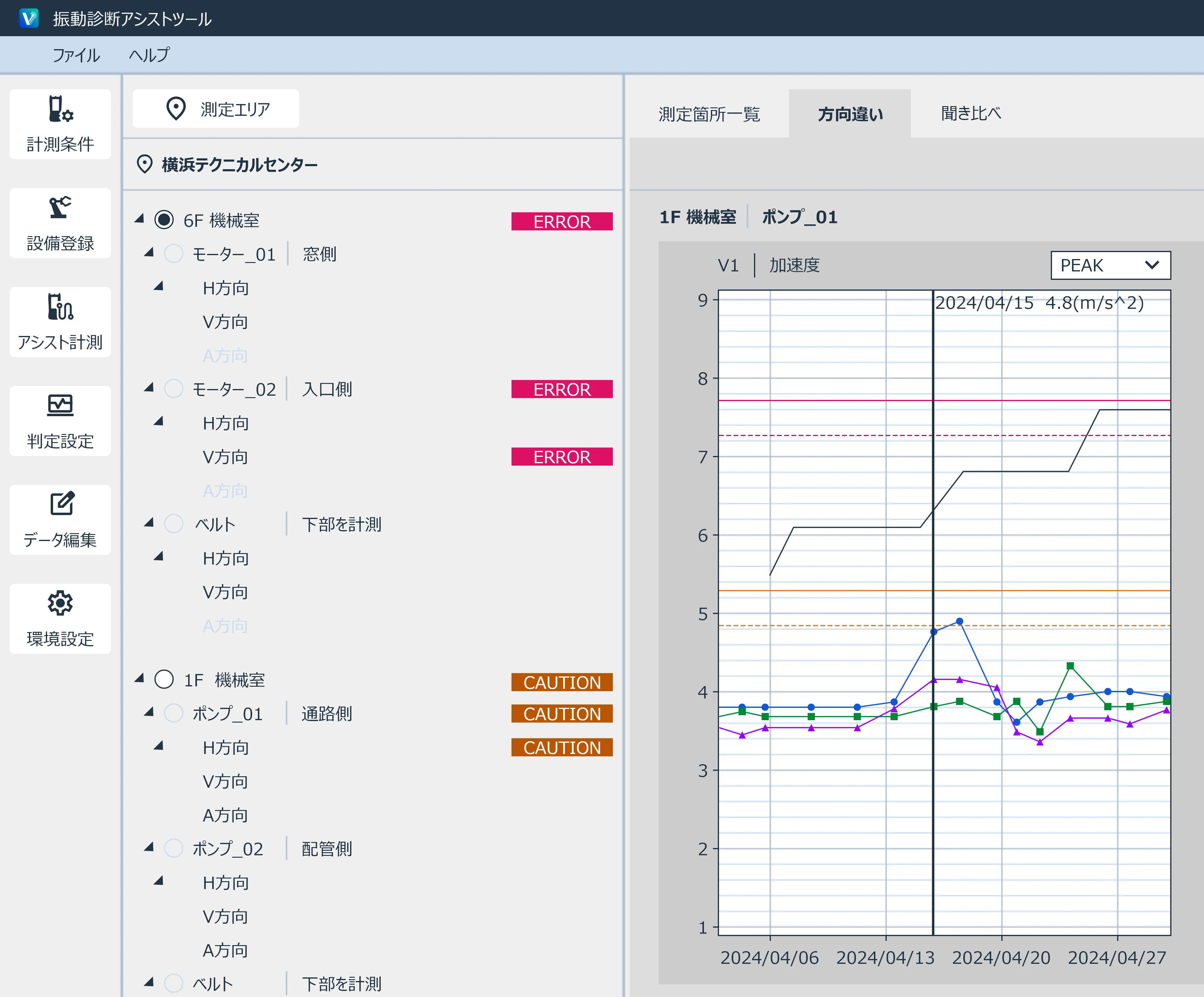

Vibration Diagnosis Assist Tool VW-0350/VW-0360

It is a PC application function that supports measurement and data management of this product. By registering measurement conditions and equipment information on a PC in advance and transmitting them to the main unit, the operator can save time by not re-setting the conditions for each machine on site, thereby enabling more efficient inspections. In addition, data acquired with the main unit can be imported into the PC, displayed on trend control graphs and playback of vibration sounds. Through regular trend monitoring using this tool, it enables from diagnosing a few units of equipment to establishing a large-scale and accurate maintenance management system.