Digital Engine Tachometer

CT-6700

The CT-6700 is a digital engine tachometer to measure revolution speed of gasoline or diesel engines, motors (EV/HEV) equipped on electric vehicles or hybrid electric vehicles or general rotating bodies.

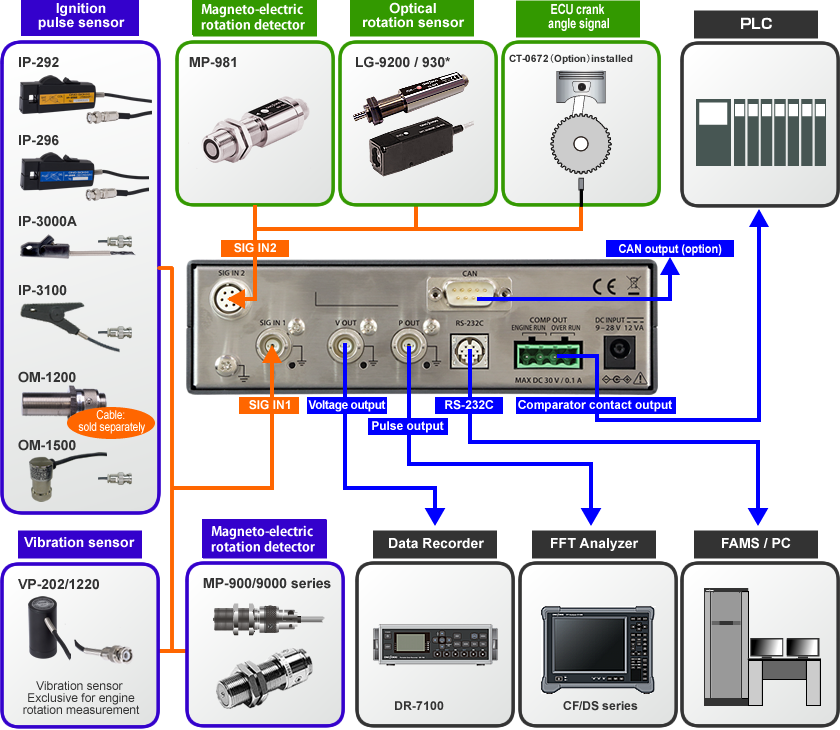

This compact tachometer supports 10 kinds of various sensors with different usages and purposes including ignition pulse detector, gasoline and diesel engine rotation detector, and magneto-electric rotation detector. Engine rotation speed has now come to be able to measure by ECU crank signal even when it is difficult to mount a detector on an actual vehicle.

Features

The CT-6700 catches transient phenomena of engine rotation speed with high response. The analog output follows up the behaviors of acceleration/deceleration within 1 cycle + 8 µs of input signal. As for pulse output, waveform-shaped output can be selected for signal output of engine rotation speed without delay.

In addition to 10 kinds of detectors such as an ignition pulse detector, gasoline/diesel engine rotation detector, magneto-electric rotation detector, ECU crank signal output becomes available. The CT-6700 measures rotation speed of various engines which is undetectable so far.

Before engine rotation measurement and motor rotation measurement, a trigger level is adjusted. Especially for the measurement using ignition signal, it is important to remove noise influence for stable measurement. This function performs trigger level adjustment automatically and helps to reduce setting time.

The CT-6700 enables rotation measurement by input of ECU crank angle signal. Since gear teeth are arranged at unequal intervals for top dead center detection, ECU crank signal is detected as unequal interval signal. The CT-6700 learns pulse pattern at unequal intervals and makes stable measurement even by input of ECU crank signal.

* CAN: Controller Area Network

Features of CT-6700 Digital Engine tachometer (YouTube)

Various functions to help measurement

Compact and space-saving design: 170(W) X 49(H) X 120(D) mm

CT-6700 has achieved size-saving design and operability in both on-vehicle measurement and engine bench measurement.

Pulse output function for tracking analysis

![]()

Rotation-tracking analysis is effective when you want to find the details of vibration source such as the component or the number of order. Tracking analysis can be performed by reading DIRECT pulse output of CT-6700 (signal for rotation synchronization) in DS series of Ono Sokki.

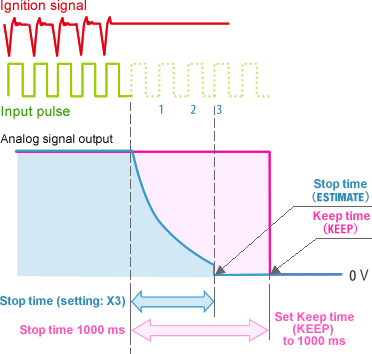

Deceleration calculation function supports the measurement in engine stop.

This is the function to decrease/stop the analog signal output when the input signal from the sensor decreases dramatically and there is no signal input over the period longer than the previous pulse interval. It estimates the signal output of rotation speed based on the last detected signal cycle, and output the analog signal.

Either of the analog signals is output, the signal estimated based on the last signal cycle detected, or 0 r/min after the specified time.

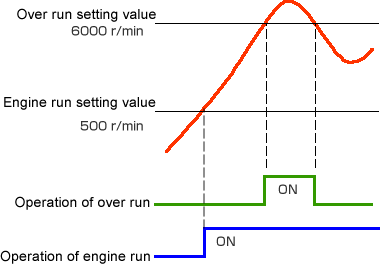

Comparator function for monitoring engine measurement condition

The above is the output operation example of the comparator when the engine run and overrun (VALUE) condition is set. If the engine run is set to 500 r/min, the engine is regarded as started when the engine rotation speed exceeds 500 r/min.

If the overrun is set to 6000 r/min, the engine is regarded as abnormal when the engine rotation speed exceeds 6000 r/min.

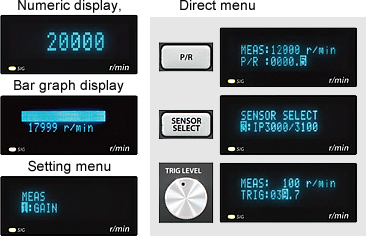

Easy to see, easy to use

Various functions are easily set by menu format and highly visible display

Frequently-used setting items such as sensor type selection, the number of pulses, and trigger level can be set by direct keys (button and a rotary dial) in a short time.

High speed digital data CAN output function(option:CT-0671)

| Baud rate (kbps) | 125, 250, 500, 1000 |

|---|---|

| Update frequency (Hz) | OFF, 1, 2, 5, 10, 20, 100, 1000 |

Rotation speed data can be output via CAN interface

Output update frequency is selectable up to 1 kHz. By an instrument with CAN interface such as CAN logger, rotation speed data can be read.

System configuration

Specification

| Input section | |

|---|---|

| Applicable sensor (sold separately) |

IP-292/IP-296, IP-3000A/IP-3100, OM-1200/OM-1500, VP-202/VP-1220, LG-9200, MP-900/MP-9000 series, MP-981, EXT(PULSE), ECU crank angle signal(option) |

| Measurement range | IP-292/IP-296/IP-3000A/IP-3100 : 120 to 20000 r/min OM-1200/OM-1500 : 120 to 20000 r/min VP-202/VP-1220 : 120 to 20000 r/min MP-900/MP-9000 series : 30 to 99999 r/min MP-981 : 0 to 99999 r/min LG-9200 : 0 to 99999 r/min EXT(PULSE) : 0 to 99999 r/min CRANK PULSE : 120 to 20000 r/min |

| Input frequency range | 0.1 Hz - 120 kHz *1 |

| Display | |

| Display method (display size) |

Fluorescent display tube (52.5 x 11.5 mm) |

| Display range | 0 to 99999 r/min *1 |

| Accuracy | ±0.01 %/F.S(±1 count)or less |

| Analog output | |

| Output range | 0 to 10 V |

| Range setting | 1 to 99999 r/min(set in steps of 1 r/min) |

| Load resistance | 100 kΩ or more |

| Response | Updates in less than 8µs after cycle becomes stable. |

| Resolution | 16 bit |

| Pulse output | |

| Output item (selectable) |

DIRECT : Wave-shaped output 0.5[P/R] : Output r/min value to obtain 0.5 P/R 1[P/R] : Output r/min value to obtain 1 P/R 60[P/R] : Manually switch r/min value output to obtain 60 P/R |

| Signal level | 0-5 V logic signal(Lo:0.4 V or less, Hi:4.5 V or less) |

| Load resistance | 100 kΩ or more |

| Contact output | |

| Item | Engine run, over run |

| Setting range | 1 to 99999 r/min |

| Contact capacity | DC 30 V/0.1 A |

| Applicable connector (cable side) |

Phoenix Contact MVSTBR2, 5/4-ST-5, 08 |

| Digital interface | RS-232C / CAN(option) |

| Other function | |

| Moving average | 2 to 720 times |

| Deceleration calculation | Selection of time or cycle Time : 1 to 1200 ms Cycle : 1.5/3/5/8/16 |

| Trigger assist | Automatic setting of trigger level employed until pulse detection |

| Resume function | Preserving condition values even while power is off. |

| Condition memory | Up to 5 types of condition memory can be saved. |

| General specification | |

| Power requirement | DC 9 to 28 V, 12 VA or less ·AC adapter(AC100-240 V, 36 VA or less) ·Input cable with fuse clips on both ends(option) |

| Outer dimensions | 170(W)× 49(H)× 120(D) mm |

| Weight | Approx. 700 g |

| Operating temperature range | 0 to 50 °C *2 |

| Operating humidity range | 5 to 85 %(with no condensation) |

| CE marking | Low Voltage Directive: 2014/35/EU EN61010-1 class1 (when AC adapter is used.) EMC Directive : 2014/30/EU EN61326-1 class1 Industrial Environment RoHS Directive : 2011/65/EU EN IEC 63000 |

| FCC | 47 CFR 15 Subpart B Class A |

| Accessory | ·Rubber foot x 4 ·AC adapter (100-240 V) for DC16 V ·Instruction Manual × 1 |

*1 In case of EXT(PULSE).

*2 Operating temperature range of the AC adapter: 0 to 40 °C

Option

Model name |

Description |

|---|---|

| CT-0671 | CAN output function |

| CT-0672 | ECU Crank Angle Signal Input Function*3 |

| CT-0673 | Panel Mounting Fixture |

| CT-0674 | Panel Mounting Fixture (CT-6520 replacement)*4 |

| CT-0675 | Protection Plate |

| CT-0676 | Light Shielding Hood |

| LC-0082 | Battery Power Cable |

| LC-0865 | Power cable for Cigarette Lighter Socket Sensor |

*3 This function enables measurement of engine rotation speed by using ECU crank angular signal.

*4 CT-0673 is required when CT-0674 is used.

Applicable sensors

Click the each product for more information

Revised:2017/01/13