Customer Reviews

Application example in control characteristic evaluation

Evaluating the control characteristics of Galvanoscanner, optimizing high-precision control and increasing scanner speed

Citizen Chiba Precision Co., Ltd.

Introduction of customer

Find Creative Solution by Customization

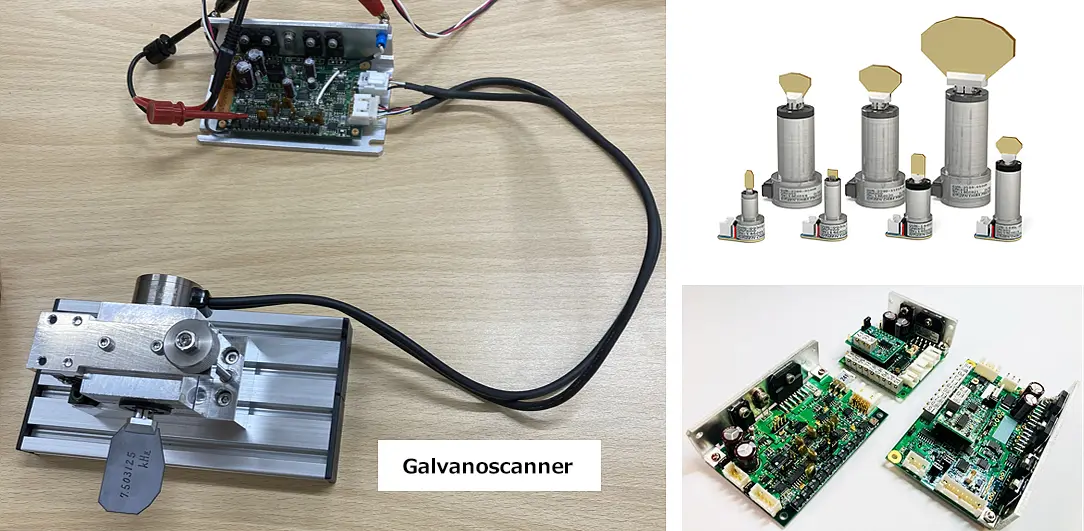

Chiba Precision Co., Ltd. was established in 1979 in Chiba, Japan, as a manufacturer of Moving Coil Type DC Motors and changed the name to CITIZEN CHIBA PRECISION CO., LTD. (hereinafter Citizen Chiba Precision) when they joined Citizen Group in 2007.

Since then, Citizen Chiba Precision have been working as the experts of miniaturized precision motors to bring new products into the global markets each year and producing customized products which fulfill their customers’ various requirements. Especially in recent years, Citizen Chiba Precision have been receiving high praise and have improved our reputaton in cutting-edge technology applications such as for semiconductor equipment, medical tools, and laser application products.

Challenges

High performance and high reliability galvanoscanner

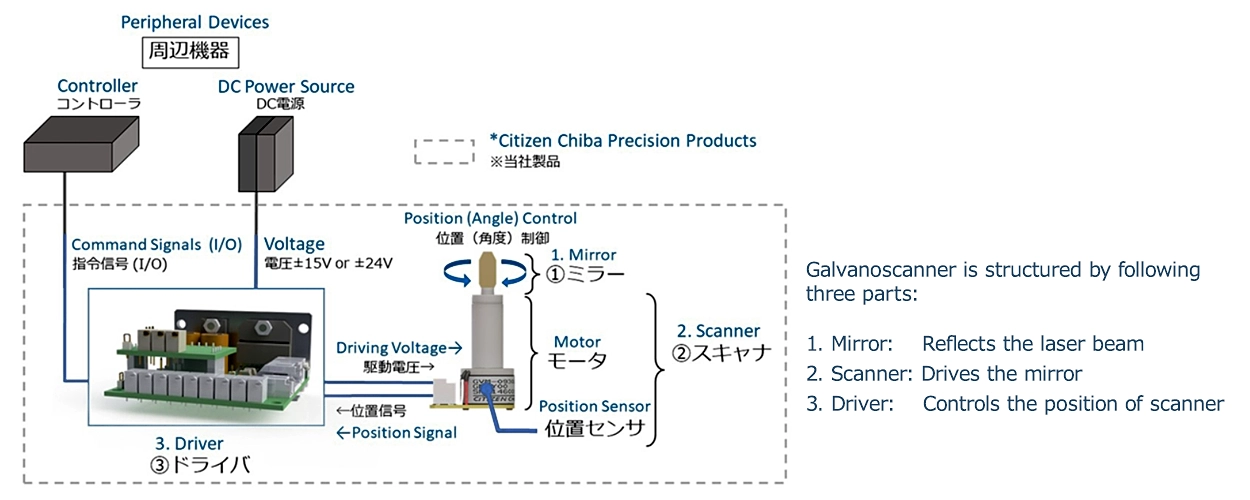

The Galvanoscanner is equipped with a motor to adjust the scanning angle of the mirror that reflects the laser beam and a high-precision position sensor. It is used in a wide range of applications in combination with laser beam, such as laser markers, microscopes, and LiDAR, and is required to scan mirrors over a wide range at high speed and with high precision. When developing products, it is necessary to perform highly accurate simulations to achieve high speeds and optimize models and control parameters. In addition, in order for customers to use products with peace of mind, it is required to confirm that the product's performance is guaranteed before shipping. Therefore, it was a challenge to easily measure and understand the control characteristics of the Galvanoscanner and the mirror's resonant frequency with high precision.

* The above information provided by Citizen Chiba Precision

Solutions

Easily understand frequency characteristics with the high-precision,

high-frequency (100 kHz) FFT analyzer and dedicated application

Reduce measurement man-hours by adding channels

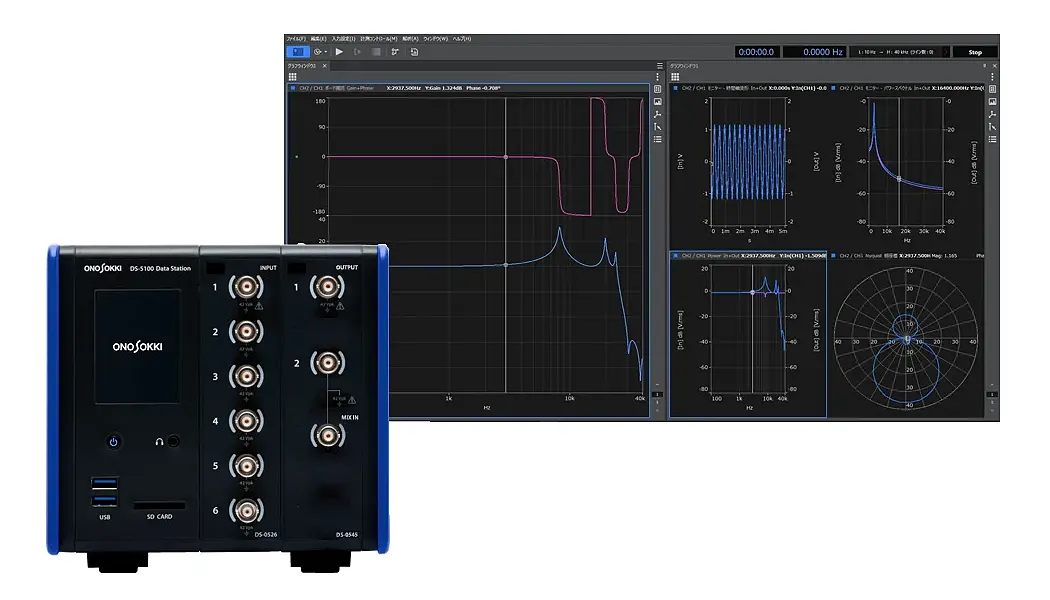

By using the DS-5000 100 kHz 4ch (FFT analyzer) and the dedicated application, OS-4100 (Frequency response measurement software) to measure frequency characteristics, we were able to conduct three types of tests with one device.

1. Reducing measurement man-hours by increasing the number of channels

So far, the measurement was performed by 2ch analyzer, 4ch one has been introduced this time. When evaluating control characteristics, two types of signals (position sensor signals and motor current signals) which respond to the command signals can be measured at the same time. By understanding these characteristics, it is useful to improve simulation accuracy and optimize control.

2. Automating settings with Auto resolution control function

When determining the mirror's resonant frequency, it is necessary to increase the frequency resolution only near the resonance. By using the Auto resolution function, the frequency resolution near resonance can be automatically increased without the setting by an operator, thereby preventing human errors.

3. Measuring safely with all channels isolated hardware

It enables to measure safely even in the field or the object where is likely to have ground loop, electrical noise and potential differences and to prevent failures due to wiring errors.

Result

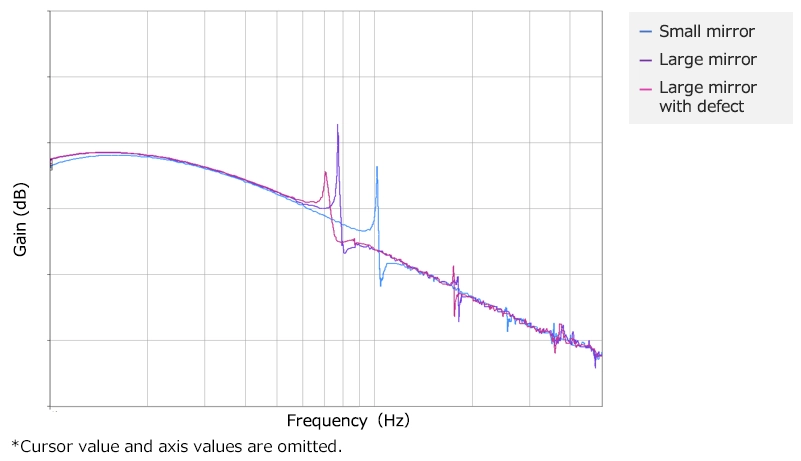

Quickly find defective products by comparing data

By overlaying the acquired data on a graph, easily understand the differences in characteristics.

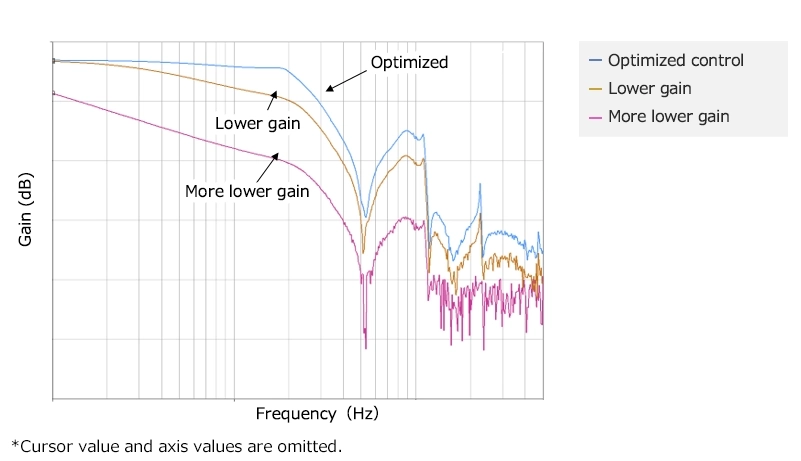

Understand changes in control characteristics

By changing the control parameters, understand how the control characteristics change.

Customer reviews

Regarding introduction of OS-4100 and DS-5000

We have been using Ono Sokki's servo analyzer (DS-3000 series) for some time, however, due to its high frequency of use, we purchased the DS-5000 with 4ch for expansion purposes. (the existing one with 2ch) When measuring control characteristics, it enables to measure position (angle) and current characteristics at the same time, leading to increased work efficiency.

We're using the DS-5000 during product shipping inspection and product development. It contributes to improving simulation accuracy in product development. In the future, we will build automation of measurement using external control and aim to reduce the man-hours for shipping inspection.

Future prospects

We plan to utilize simulation model optimization and deep learning to develop galvano mirrors with even higher response and higher quality. Galvano mirrors are installed in semiconductor inspection equipment, medical equipment (e.g. fundus examination equipment), processing machines (laser marking), and automobiles (LiDAR, etc.). In order to contribute to these industries, we will continue to develop and manufacture high quality and highly responsive galvano mirrors.

Person in charge of Control Device Section, R&D Department, Citizen Chiba Precision Co., Ltd.

Products for solutions

PC based Frequency Characteristics Analyzer Achieves high-speed, high-precision frequency response measurement

The OS-4000 series is dedicated software that can measure the frequency characteristic of various objects with high precision and high speed, such as vibration characteristics of mechanical structures, acoustic characteristics of speakers, motor control characteristics, servo analysis, coupling response characteristics, and battery impedance characteristics. This system can be used as a servo analyzer and frequency characteristic analyzer and obtain frequency characteristic easily, quickly, and with high resolution.

Frequency response measurement software OS-4100

(Servo Analyzer / Frequency Characteristics Analyzer)

Revised: 2024/03/05