If damage of facility, equipment etc. is found at an early stage, it is minimal.

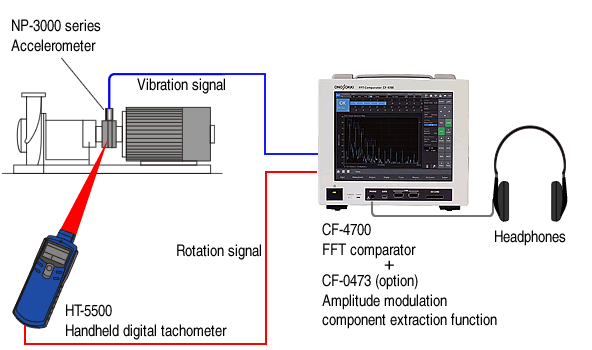

In this example, FFT analyzer performs frequency analysis on abnormal vibration of a rolling bearing to diagnose whether the bearing is damaged or not.

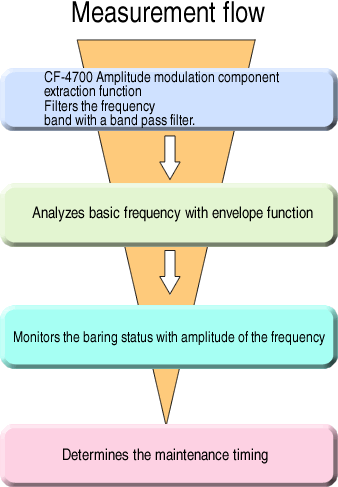

<Measurement procedure>

1) Input the signal from an accelerometer attached on the rolling bearing into the CF-4700 FFT comparator.

2) Filter the frequency band of vibration caused by damage with the amplitude modulation component extraction function

(optional), and analyze the basic frequency corresponding to the damaged sections by the envelope function.

3) Diagnose the bearing status with the amplitude of that frequency and determine the maintenance timing.

In addition, you can set the filter while listening to the sound with headphones.

Configuration

| Model name | Item name | Remarks | |

|---|---|---|---|

1 |

CF-4700 | FFT comparator | |

2 |

CF-0473 (option) | Amplitude modulation component extraction function | |

3 |

NP-3000 series | Accelerometer (with built-in preamplifier) | With CCLD (or TEDS) function |

4 |

HT-5500 | Handheald digital tachometer | Detects 1 rotation per pulse (reflective mark) |

Key points

Revised:2018/10/31