One procedure to check if the torque detector is breakdown or not is to check "Is the zero correction value changed significantly compare to it at the time of shipment?".

Zero value is set automatically when the zero correction is operated while the torque detector is in no-load state. After setting, load the zero correction value to check if the value is changed ±100 or more compare to it at the time of shipment. (It is written in the certification of test result which is attached at the time of shipment.)

Following causes can be determined when the value is significantly different. The small difference can be determined as normal range due to temperature change or aging, but after many years of use, inspection calibration (charged) is recommended.

Please note that the zero correction values are different depending on the CW/CCW setting.

Causes of the change of the zero correction value

1. The power of the torque detector is not turned ON.

Breakdown of the torque detector

If an error does not apply to the above 1 to 5 causes, the detailed confirmation such as linearity is necessary with the detector calibration. Please operate followings before asking for examines and repairs.

1. Turn the power of the torque detector ON. Operate the zero correction again after checking the detector is in no-load state.

2. Operate the zero correction while removing the coupling of one shaft side of the torque detector at least.

3. Match the rotation direction setting of the

auxiliary motor and the shaft which is viewed from the [drive

side] sticker on the detector. (Please refer to "How

to check the rotation direction of a motor attached to the SS

series torque detector.".)

4. Match the rotation direction settings of the detector side and TS-2700 side.

5. Calibrate with the detection quantity. (Please

refer to the "Calibration of torque

detectors".)

6. Consider the inspection calibration or repair request to Ono Sokki. (Please contact your nearest distributor or send us an email. overseas@ONO SOKKI.co.jp)

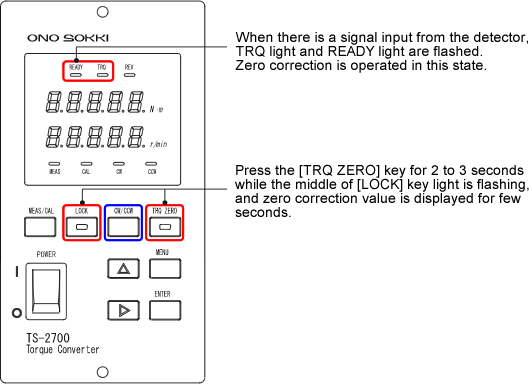

Checking operation of zero correction value

Press [LOCK] key to flash the light and press [TRQ ZERO] key while flashing. Displays zero correction value which is set in the torque display window for few seconds and return to the torque display. The rotation direction setting of CW/CCW is changed every time [CW/CCW] key is pressed after canceling the [LOCK]. Please check each zero correction value.

Note when switching CW/CCW

Each setting cannot be operated when the [LOCK] key light is flashed. To cancel the activation, press [LOCK] key again to turn the light OFF.

Revised:2009/05/25