(1) Calibration period of torque detector

Torsion bar results in some amount of aging (G transverse elasticity coefficient), and change in static torque characteristic errors due to its material characteristics. Perform calibration tests again and adjust the Factor to keep the precision.

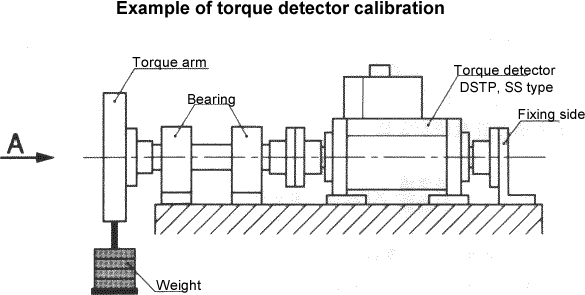

Static calibration of SS type, DSTP type and DD type can be performed in the following procedure. To gain good performance, please perform calibration half-yearly or yearly.

Prepare one-end shaft lock mechanism and weight etc in advance for smooth calibration.

Calibration of detectors, TS series torque meter can be performed by Ono Sokki. (It is required to send the products to Ono Sokki for the calibration test.) Please contact the nearest sales office.

(2) Calibration procedure of torque detectors

1. Turn off the driving mechanism.

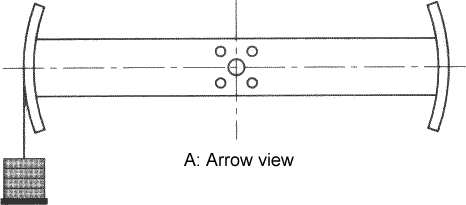

2. Attach the calibration arm to the shaft-end of one side.

3. Install the ribbon to the hook.

4. Making zero adjustment of the TS series torque meter.

5. Set weight to the ribbon and record the torque.

* Please perform calibration with the torque within the rated torque.

6. Record the Factor, Range and Zero temperature of the torque meter, date and time at the time of calibration.

When length from a shaft center to an arm end is L (m), weight of balance weight is W (kg);

L×W×9.807 (Nm)

(3) Calibration method of torque detectors (determination of factor)

Determine the Factor by loading torque that is used as standard of detectors. Zero Adjustment should be performed in the state of loading no torque to the detector. Before shipment, the detector is calibrated, set the Factor and Range. Those are marked on the name plate of detectors.

1. Set the Factor and Range of the TS series in reference to the values marked on the name plate.

2. Set Zero Adjust to 00000.

3. Read the displayed value in this status and set that value as Zero Adjust. Then 000000 is displayed.

(Example)

| Displayed value of no-load and Zero Adjust=00000 | 10195 |

| Zero Adjust setting value | 10195 |

| After Zero Adjust settings | 00000 |

4. Apply the rated load (reference value) to the detector, and compare the reference value and measurement value.

Revised:2000/06/07