Facilities in a factory need everyday monitoring to prevent accidents like a line stop. The vibrations of parts such as bearings are monitored to make replacement at an appropriate time. In many cases, the replacement time is decided by tests with human sense such as hearing vibration sound of the monitoring point using a stethoscopic probe or screw driver. Even when a handheld Vibrometer is used, periodical check needs a lot of work and time.

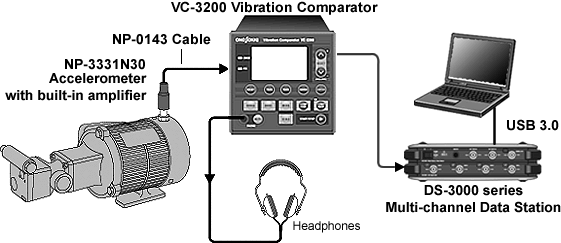

This example shows a constant monitoring system for abnormal diagnosis using the VC-2200/3200 vibration comparator. The VC-2200/3200 monitors the vibration value detected by the accelerometer. This system enables constant monitoring of abnormal vibration from the machinery as well as the parts like bearings (Basic diagnosis). You also can analyze details of the abnormality with the FFT analyzer. The FFT analysis gives precise analysis in waveform of the abnormality of inner race, outer race or rolling element of bearings (Precise diagnosis).

Configuration

| Model name | Product name | Remarks | |

|---|---|---|---|

| 1 | VC-3200 | Vibration comparator | The VC-2200 Vibration comparator can be applicable. |

| 2 | NP-3000 series | Accelerometer with built-in amplifier | |

| 3 | DS-3000 series | Multi-channel data station | DS-3204 4ch Main unit DS-0321 FFT Analysis function DS-0350 Recording function USB 3.0 Cable (2 m) |

Feature

Effects

For better solution

Mount the accelerometer on the bearing section of the motor load side.

Measure both directions of radial and thrust. You can find flaw of bearings at radial direction, rotation imbalance at thrust direction.

When the abnormality is occurred during basic diagnosis using VC-2200/3100, use the FFT Analyzer for precise diagnosis.

Obtain the average value as a judgment level. The followings provide an indication of the value;

Caution; quadruple or more of the judgment level.

Danger; ten times of the judgment level.

∗Please grease up before the average measurement.

Revised:2018/04/10