Why do they need the master piece calibration during the thickness measurement of conductor and semiconductor by Non-contact Thickness/Displacement Meter?

The CL series of Non-contact Thickness/Displacement Meter is calculating the thickness from the gap measurement value. If you do not know the gap between two sensors, you cannot calculate the thickness from the gap value. In this reason, master piece calibration is necessary to decide the gap between two sensors.

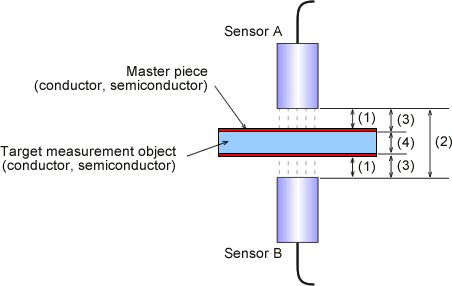

Process from the master piece calibration to the thickness measurement

1. Insert the master piece between two sensors, and then measure gaps (1) between each of them.

2. Determined the gap (2) between two sensors from the thickness of the master piece and the gap values (1) from above measurement.

3. Insert the target measurement object and measure each gap (3) from both sensors.

4. Calculate the thickness of the target measurement object (4) by subtracting the gap value (3) from the gap value (2).

You can freely set the measurement thickness value from changing the fixing position of the sensor. Therefore, it is possible to do the high resolution measurement with very thick object.

Revised:2011/04/18