(1)Coupling and centering

Coupling centering accuracy varies depending on the rotation speed and type of coupling, however it should be kept within 0.05 mm (T.I.R :Total Indicator Reading, difference between maximum and minimum measured values).

Use a flexible coupling. If the machine and coupling are not properly centered, a large bending force will occur in the detector shaft, possibly resulting in damage to the bearings or shaft breakage.

When a load resulting from displacement of the shaft due to the spring constant is large, it is very important to ensure the highest degree of centering accuracy even if within the allowable dimensions. If abnormal noises emanate from the coupling, re-center until the noise is eliminated. Greater centering accuracy is required as speed of rotation increases.

Thrust loads should be kept to approximately the mass of the

coupling.

See also the Torquemeter FAQ 「Coupling selection and centering accuracy」.

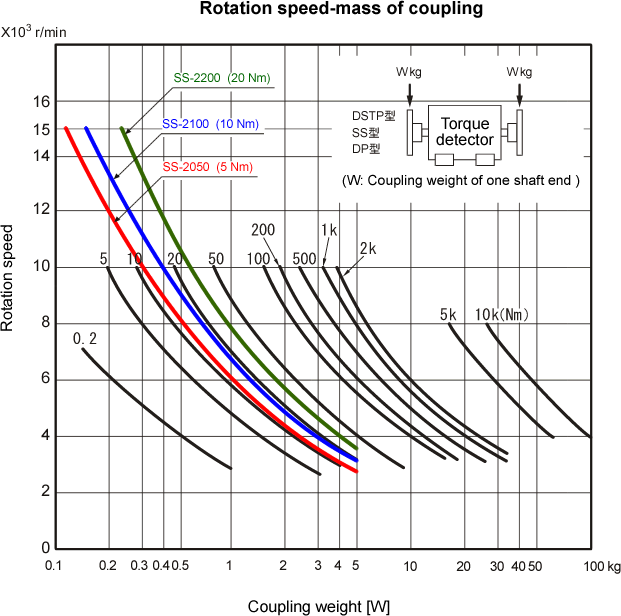

(2)

Coupling selection

The mass of the coupling fitted

to the detector is determined by the maximum speed of rotation

used. Select from the curve for the detector rating in the

following table.

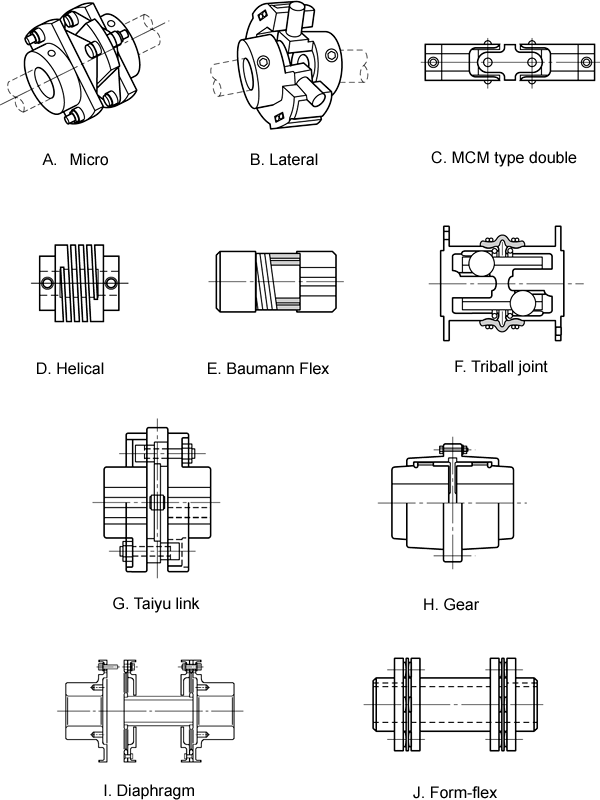

Shapes and characteristics of

couplings differ by manufacturer. The drawings below show

couplings rated up to 4000 rpm. Care is required with dynamic

balance, eccentricity, and angular deviation, etc. when used at

speeds of 4000 rpm or more. It is recommended that comparatively

small-capacity detectors be of non-magnetic material to avoid

magnetic effects. Contact the coupling manufacturer for details.

We are able to provide a detector and coupling as a set.

(3)

Coupling fit

An interference fit is required

when coupling to the end of the shaft. A clearance fit may

result in corrosion of the end of the shaft, with consequent

change in strength and dimensions, and failure. The normal

interference is between 5D/10000 and 1D/10000 (D: shaft

diameter). Apply molybdenum dioxide, etc. to the fitted surfaces

as a lubricant.

Revised:2006/06/09