Torque Station Pro

TS-7700B

| MT series Torque Detector |

Personal Computer TS-7700B Torque Station Pro |

The TS-7700B Torque Station is designed to automatically measure motor torque characteristics, which are evaluated in development and product inspection of motor and motor driver, in combination with MT series torque detector. The system provides user-friendly application software, enabling easy operation, with secondary data processing using spread sheet application. Max. 16 kinds of input signal can be measured as well as torque and revolution at once. Moreover, motor characteristics can be shown in graph format after measurement and comparator function expands capability of usage in quality control.

The TS-7700B system can also be combined with detector corresponding to cogging torque measurement, which is considered to be important data for motor efficiency and noise reduction, and can be displayed in the graph.

A wide range of MT series detector has been provided for use with the TS-7700B torque station and can meet a variety of requirement of motor test.

Features

· Automatic Saving of Measurement Results

The measurement results can be saved automatically to a file without any need for file-saving operations. Eliminating the need to input a file name shortens the overall measurement time.· Output of Specified Value Data

The measured data at specified points can be displayed in a list format. This display method is faster than using cursors on a graph to select data for display, and therefore enables faster confirmation of measured values.· Measurement Data Secondary Processing Functions

Several processing functions, such as the smoothing of data fluctuations during low revolutions, the combining of data from several measurement operations, and the addition of no-load data, are provided.

· Comparator Function

This function enables comparison and judgment of the upper and lower limits. The judgment results are displayed on the screen, and can be output externally if required.· Component Analysis of Torque Ripple and Cogging Torque

This function analyzes the size of the cyclic variations that occur during one revolution, for each cycle, and identifies the primary factor influencing the overall torque variations.Examples of data

Graph display of motor characteristics

Efficiency calculation display enabled

a separately-available current/voltage detector required for some models

Data table (Secondary use processing enabled using spread sheet application software)

Example of cogging torque data

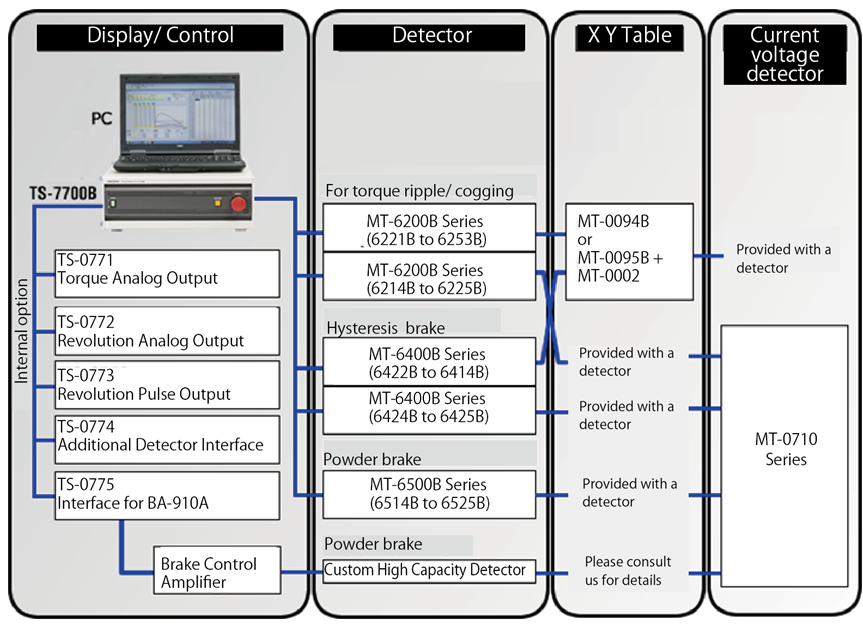

System Configuration

Specifications

| Applicable motors | DC motors, AC motors (stepping motors excluded) |

|---|---|

| Measurement parameters | Torque, revolution, voltage signal input data |

| Torque input | Use signals from Ono Sokki’s dedicated detectors. |

| Revolution input | Use signals from Ono Sokki’s MP-981 or RP series detectors. |

| Analog input | 0 to ±10 VDC, 16 channels with 16-bit A/D converters |

| Measurement accuracy (1-second averaged value) |

Torque: ±0.2%/full scale Revolutions: ±0.02%/full scale Analog: ±0.2%/full scale |

| Computation settings | 4 user-specified settings (arithmetic operations only) based on the input signals and existing computed data. |

| Measurement condition settings | Torque meter and tachometer settings Control method: Revolution/torque control Measurement mode: Automatic/manual All these settings can be assigned a file name and saved. |

| Measurement functions | Sweep - Measurement time: 2 to 1,000 seconds, No. of data: 512 or 1024 Overlaid measurement 4-point measurement |

| Monitor display | Numeric values display: A maximum of 23 data items can be displayed simultaneously. Trend display: Time axis display |

| Graph display | Specified X-axis and Y-axis display from the measured data Graph enlargement/reduction, line colors and line widths specifiable Comment input, text can be displayed on the graph and saved. Cursor, peak search functions |

| Table display | List display of measured values, Data editing function |

| Comparator | Upper/lower limit specification of specified parameters, up to a maximum of 20 points Display and output of the judgment results |

| MT Series detector interface | 2 channels, an additional two channels available as an option |

| Saving of measurement results | Data saved in the computer’s own proprietary format or as a text format. |

| Compatible computers | OS: Windows 7 Professional (32-bit), Windows 7 Professional (64-bit), Windows 10 Professional (64-bit) |

| Operating temperature range | 5 to +35 °C |

| Operating power supply | 100 to 240 VAC, 50/60 Hz |

| Power consumption | 100 VA (100 VAC) or less |

| Weight | Approx. 14 kg |

| Standard accessories | AC power cable, application software (CD-ROM), USB cable (2m) |

Option (sold separately)

| TS-0771 Torque Analog Output |

Output format: Voltage 0 to ±10 V/ full scale Response: 16 ms to 1 s |

TS-0772 Revolution Analog Output |

Output format: Voltage 0 to +10 V/ full scale Response: 16 ms to 1 s |

|---|---|---|---|

| TS-0773 Revolution Pulse Output |

Output: Outputs converted revolution input signals Output format : Output by pulled up to +5 V with 340 Ω register. |

TS-0774 Additional Detector Interface |

This interface adds two channels to the detector connector, and enables computer switching of the connector used. |

| TS-0775 Interface for BA-910A |

This interface is required when using the MT-6555B, 6516B and 6526B torque detectors. |

Revised:2018/05/14