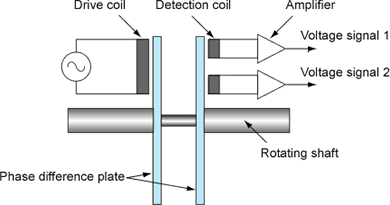

Operating principle of Digital Torque Meter

When power is transmitted by a shaft, the shaft undergoes a torsional twisting through an angle which is proportional to the transmitted torque. A digital torque meter coupled to non-contact type electroMagnetic Detectors facing gears mounted at two points on the shaft detects the torsion angle as the phase difference between two AC signal voltages. Some ingenious digital processing, referenced to a highly accurate and stable crystal oscillator, converts the phase difference into a measurement of the transmitted torque.

The torsion angel can be detected by inserting a torque detector at a point on the torque transmission shaft or direct detection by coupling a torque detector to a shaft. A motor rotates a suspended rotating column of a torque detector and an internal-toothed gear coupled to it, so even when the shaft (externally toothed-gear) is stationary, there is a speed differential between the two gears. The magnetic flux in the coil therefore fluctuates as the internally-toothed gear turns through its circular pitch, generating an AC voltage with a sine waveform. And then torque applied to a stationary shaft can also be measured.

Detection principle of the New Magnetic Phase Difference method