Applications Torque Meter

Torque Meter Monitoring

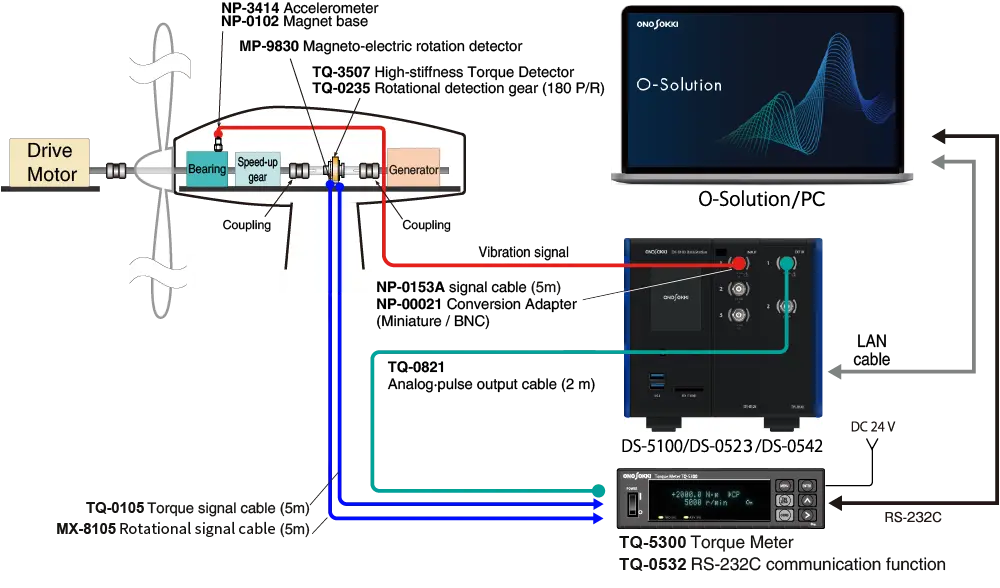

A-1-2 Simultaneous measurement·analysis of cogging torque and bearing vibration using wind-powered electricity (or dynamo)

- The increase of cogging torque not only decreases effectiveness in energy but also is deeply related to noise and vibration problems. This example shows how to analyze the correlation with cogging torque and vibration.

- First, measure and monitor the cogging torque from wind power generator blades, and then perform real-time frequency analysis of the vibration generated.

Product list

| Model | Product name | Remarks | Qty | |||

|---|---|---|---|---|---|---|

| 1 | TQ-3507 | Flange type High-stiffness Torque detector | 1 | |||

| 2 | TQ-0235 | Rotational detection gear (180 P/R) | 1 | |||

| 3 | MP-9830 | Magneto-electric rotational detector | 1 | |||

| 4 | NP-3414 | Accelerometer with built-in preamplifier | 1 | |||

| 5 | NP-0102 | Magnetic baser | Mass: 10 g, adsorption power: 29.4N | 1 | ||

| 6 | NP-0021 | Miniature/BNC conversion connector | Converts the NP-0153 signal cable terminal to BNC connector and input to the DS-5000 series BNC connector. |

1 | ||

| 7 | TQ-5300 | Torque Meter | 1 | |||

| 8 | TQ-0532 | RS-232C communication function | 1 | |||

| 9 | TQ-0821 | Analog·pulse output cable (2 m) | 1 | |||

| 10 | O-Solution DS-5000 | 3ch 40 kHz Tracking set | DS-5100 Main Unit DS-0523 3ch 40 kHz Input Unit OS-5100 Platform OS-0522 Tracking Function OS-0523 Octave Analysis Function OS-0512 Hardware Connecting Function |

1 | ||

| 11 | NP-0153A | Signal cable for the NP-3414 (5m) | 1 | |||

| 12 | MX-8105 | Signal cable (5 m) | 1 | |||

| 13 | TQ-0105 | Torque cable (5 m) | 1 | 1 | ||

|

||||||