Possible causes are as follows.

(1) The power of the torque detector is not turned ON. (The switch is in neutral setting.)

(2) ZERO correction is not operated correctly.

(3) The actual torque is applied.

(4) Error of rotation direction setting.

(5) Possibility of breakdown.

Factor (2) may occur when you use the unit for the first time.

It is necessary to operate ZERO correction after setting the menu of [CAPACITY] and [FACTOR] according to the torque detector. In the case of operating ZERO correction with an error, the possible factors are as follows.

1. The power of the torque detector is not turned ON (Switch is in neutral setting).

The switch of the torque detector (SS series and MD series) can be selected from three positions of neutral (Power OFF), CW and CCW. The neutral is in a central position of the switch.

The signal is not generated with the neutral state, so it cannot be to set ZERO correction value appropriately. At the time of measurement, set CW or CCW of the detector according to the rotation direction to be measured. (For the detector which has no CW/CCW changeover switch, please refer to the instruction manual of it.)

2. Zero correction is not performed correctly.

2-1 CW/CCW setting is inappropriate.

Zero correction values are different depending on the rotation direction (CW/CCW) of the torque detector shaft. Therefore, it is necessary to operate zero correction for each of the CW and CCW directions. The rotation directions (CW/CCW) are defined when you view the shaft from the side on which [drive side] sticker of the torque detector is put. The CW/CCW of the torque detector is set by the switch, and the TS-2700 is set by [CW/CCW] key. Please perform Zero correction after matching the CW/CCW setting of the detector side and display side.

2-2 Proper Zero correction.

Please refer to the following procedure for Zero correction.

3. Zero correction has not been operated even it is in a No-load state.

When the coupling is connected, the shaft is not in the no-load state even the rotation is stopped. When the zero correction is made in above state, the correction value is set to display "0" to the torque meter with a consideration of actual applied torque. Check that it is in no-load state and make zero correction. When the shaft can be rotated with light force such as a hand, it is in no-load state. Or remove the coupling from the load side of the torque detector.

4. Error of rotation direction setting

After zero correction, correctly set CW/CCW of the torque detector and TS-2700 according to the direction to be measured, and start measurement. When the switch of the detector is in neutral, the power is turned OFF. The outline of the zero correction operation is as follows.

Zero correction procedure

When you use the torque meter for the first time, please follow the procedure of zero correction and measurement as below. For detail, please refer to the instruction manual of the TS-2700.

1. Connect the torque detector and TS-2700 with the exclusive cable.

2. Connect each power of the torque detector and TS-2700.

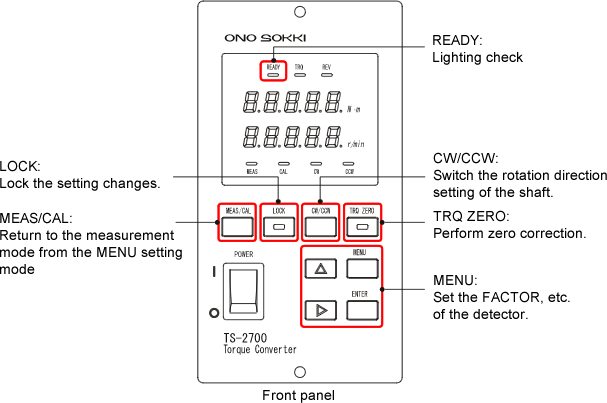

3. Press the [MENU] key of the TS-2700 for 2 s or more and start menu setting mode.

4. Set each item of the menu such as [CAPACITY] and [FACTOR] according to the torque detector. For the operation, please refer to the instruction manual of the TS-2700.

5. Press [MEAS/CAL] key of the TS-2700 to return to the measurement mode.

6. Set the CW (lights up) by pressing [CW/CCW] key of the TS-2700.

7. Set the torque detector to CW (→ is in clockwise side) by the switch.

8. The power of the torque detector is tuned ON and the attached motor starts to be rotated. Please note that the switch has three positions of neutral, CW and CCW.

9. Check if the torque detector is in no-load state or not.

10. Also, check the [READY] of the TS-2700 is lit up. (Check whether or not the signal is received normally or not.) If the READY is not lit up, it is thought that the power of the detector is not turned ON, the switch is in neutral state, etc.

11. Press the [TRQ ZERO] key of the TS-2700 for 2 s or more. The zero correction value is automatically set and torque display becomes zero. This is the end of the zero correction for CW.

12. Perform above 1 to 8 for the CCW setting.

13. Set the CW/CCW of the torque detector and TS-2700 according to the shaft direction to be measured and start measurement.

Use as the breakdown check.

Zero correction value is sometimes used for checking if the torque detector is broken or not. If the Zero correction value has been significantly changed compared to the value at the time of shipment, it might be broken.

Revised:2009/05/25