Is it ok to attach the detector vertically?

In that case, what are the points to be aware of?

It is possible to attach the detector vertically. However, the load should be about the coupling weight.

There is not a problem even if the detector is installed on the side surface, upside down (rear side), but the installation surface is necessary to be a surface plate with sufficient strength. Please attach it in consideration of ease of cable removal and maintenance.

Select the centering accuracy in 2 to 3/100 mm.

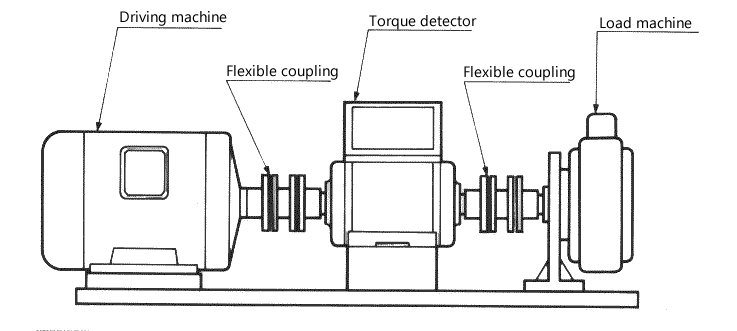

The following is the general attachment example.

(1) When no fluctuation weight is applied to the shaft

Connect with the external device by using the flexible coupling.

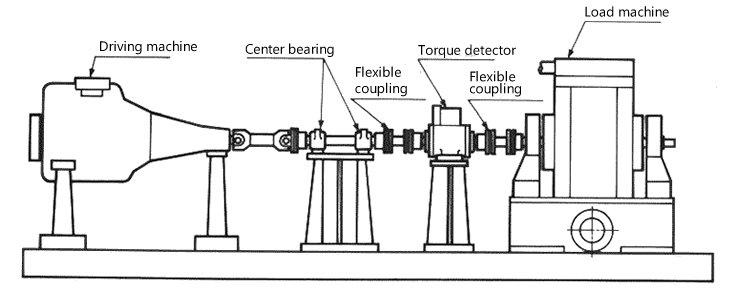

(2) When fluctuation weight is applied to the shaft

Place the intermediate bearing so that no fluctuating load is applied to the shaft end of the torque detector.

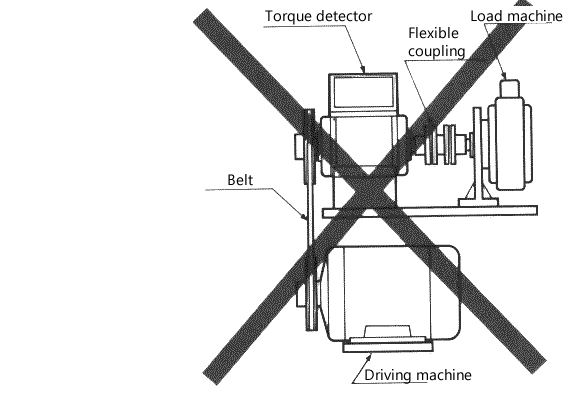

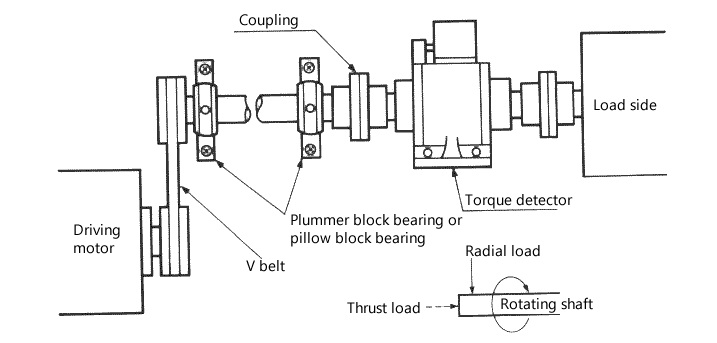

(3) Prohibition of driving by belt chains and gears

As shown in the figure below, loading belt pulleys, sprockets, and gears used for chains, etc. directly on the shaft of the torque detector will transmit a large load to the axis of the detector. This not only has a bad influence on the torque measurement but also possibility of damaging the bearing supporting the shaft.

By placing an intermediate bearing between the detector and the drive motor as shown in the figure below, even if tension is applied to the belt by driving with the V-belt, measurement can be performed accurately without causing bending of the axis of the detector.

(4) When attaching vertically

The detector can be attached vertically. Please refer to (1) to (3) for attachment.

Please consider that the thrust weight applied to the detector is about the same as the coupling weight added to the using torque detector side.

Revised:2017/06/30