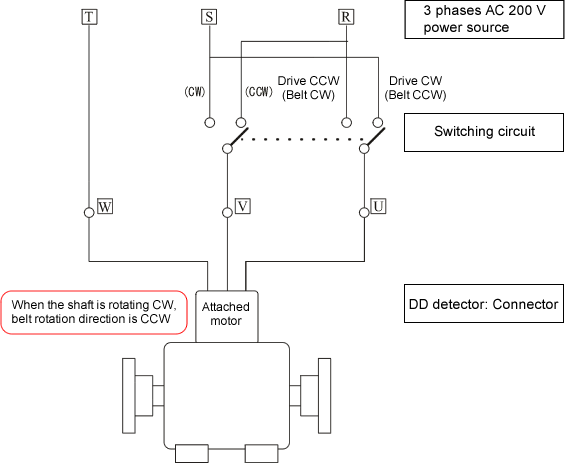

To change the rotation direction, switch the 2 of 3 phases (200 V) of the motor attached to the DD series torque detector. Please refer to the following wire connection method.

Wire connection method

Attached motor specification

| Model name | Power source | Number of polarity | Electricity consumption (VA) |

|---|---|---|---|

| DD-503, 104, 204 | AC200V | 3-phase 4-pole | 25 |

| DD-504 | |||

| DD-505, 106, 206 | 50 | ||

| DD-1506B, 1107B, 1207B | |||

| DD-507 | 140 | ||

| DD-108 |

Caution

Please set the belt rotation direction of the motor reverse to the shaft rotating direction.Connector pin arrangement

[Connector pin arrangement]

Power cable (AC200/220V)

Detector side: MS3106B 18-1S

| Pin No. | Signal name | |

|---|---|---|

| A | U | Detector attached motor AC200/220V |

| B | V | |

| C | W | |

| D | U | Option (for lubrication equipment) |

| E | V | |

| F | W | |

| G | COM | Option (for alarm) |

| H | TEMP-1 | |

| I | TEMP-2 | |

| J | Shaft lock | |

| Case | Earth | - |

* AC220V is option.

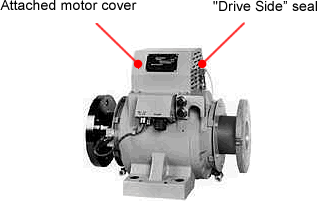

Remove the motor cover and see the rotation direction of the motor belt to check the direction by visual contact.

Belt rotation direction (as viewed from "Drive Side" nameplate)

● The shaft is rotating CW (Clockwise), belt rotation direction is CCW … Drive CW

● The shaft is rotating CCW (Counterclockwise), belt rotation direction is CW … Drive CCW

Switch the power circuit to rotate as above. Also, use the attached cable (5 m) for the cover cable of the detector. Please judge the rotating direction in view of "Drive Side" seal so as not to make a mistake.

Caution:

Do not touch the belt when you remove the cover. There is danger being rolled in the machine.

Revised:2009/01/19