If the noise is generated in the torque signal, a certain problem may happen, such as;

• Despite of unloading state, the displayed value is always different.

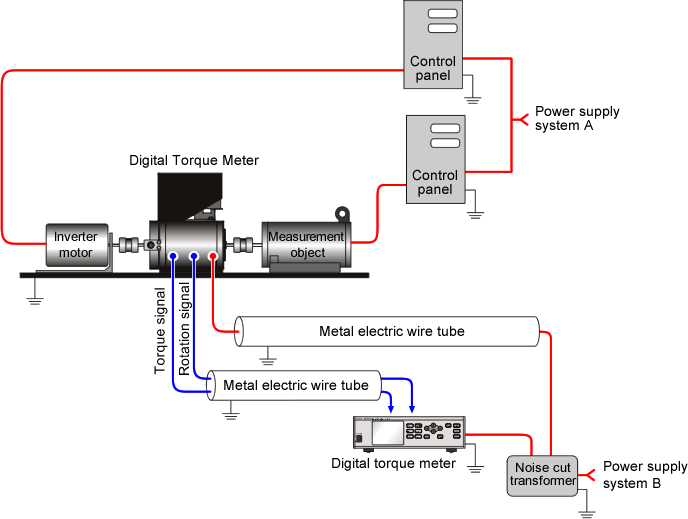

In recent years, increasing number of test devices using inverter or measuring inverters has been used. An inverter emits noise because of the operating principle and may affect other devices near it. Torque meters are not an exception. The degree of effect depends on the amount of noise generation, installation condition of signal lines, device installation condition, distance between the inverter and device, and other factors. Trouble caused by noise from the inverter can be reduced by observing the following precautions on wiring installation. For other causes than noise from the inverter, it is recommended that the following precautions be observed at the time of installation.

1. Take measures for radiation noise on the side of the inverter unit and the motor.

2. Separate the input and output lines of the main circuit of the inverter from the power and signal lines of the torque meter (cables for torque counters and rotational counters). The rough standard distance of separation is 300mm or more. If separation is difficult or ineffective, apply metal conduit tubes to the power and signal lines of the torque meter and then connect one side of the metal part to a good ground.

3. Use the supplied cables for the power and signal lines of the torque meter.

4. Connect the rack for the torque detector to a good ground.

5. If the TS series digital torque meter has 3P electric plugs, you need to use 3 of them and connect the earth terminal to a good ground. If it is 2P, use the case earth terminal fixed to back of the TS series digital torque meter and connect to a good ground.

6. The power for the TS series digital torque meter is considering as a different category as the power for the inverter. If it is not possible, provide the noise cut transformer.

7. Follow the noise reduction measure provided by the inverter manufacturer.

Revised:2000/06/09