Torquemeter TH series FAQ

| Magnetic phase difference method (using gear) | New magnetic phase difference method (using electromagnetic induction theor) | |

|---|---|---|

| Detectors | SS/MD/DD/EZ/DSTP series |

TH series |

| Phase difference calculation method | Double gate method (averaging for a given length of time) |

Instantaneous phase difference method (measuring with respect to one-phase difference) |

| Motor/AC power source | AC power is required because an auxiliary motor drives a rotating hollow cylinder with internal tooth gear in a detector. |

Motor and AC power is not required because AC magnetic field is generated inside the detector. |

| Setup | Set up characteristic data of a torque detector (factor or zero etc.) on a display. (Characteristic data is written in the model plate.) |

Set up characteristic data of a torque detector (factor or zero etc.) to a torque meter automatically when the power is on. |

| Accuracy | ±0.2 %/F.S. |

±0.1 %/F.S. |

| CE marking | SS-E series only |

All TH series |

| Signal from detector to display unit (torque meter) | Phase difference of sine wave signal |

Phase difference of pulse signal (line driver output) |

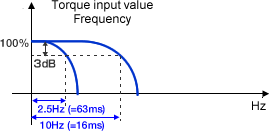

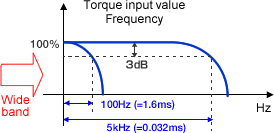

| Max. frequency response(*1)

Reading speed of analog output variation |

10 Hz |

Standard:100 Hz |

Setup by time constant Standard: 63 ms (TS-2700) |

Can be setup by time constant or by cut off frequency. • Time constant standard: 1.6 ms |

|

|

|

|

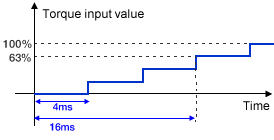

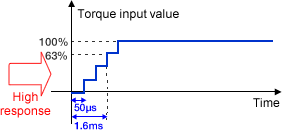

| Update time

Time interval of measuring time |

Every 4 ms |

Every 50 µs |

|

|

|

| Rotation direction(CW/CCW) | External rotation direction selector is required. |

Rotation direction selector is not required. |

*1. Response can be changed by time constant setting value of a torque meter. Mechanical response has restriction by inertia moment and spring constant of the torque meter, specimens connected with the torque meter.

SS series and TH series have same dimensions of mounting hole, center height, and shaft diameter.

Revised:2012/07/17