The operation principle of the MP-981

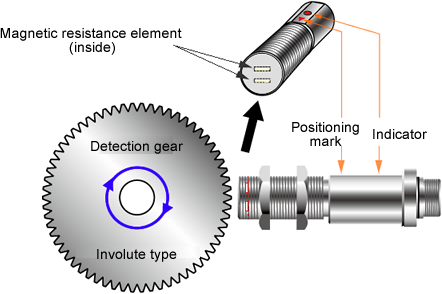

The magnetic resistance element, permanent magnet, DC (direct current) amplifier and voltage regulator are incorporated in the MP-981 Magneto-electric Detector. The detector measures the rotation speed of the detection gear from ultra low speed to high speed (1 Hz to 20 kHz).

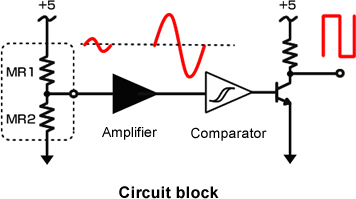

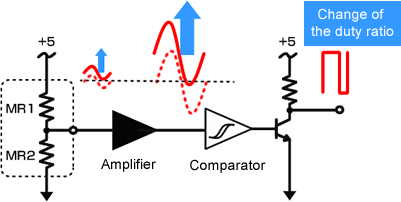

The detection part of the MP-981 sensor edge has the magnetic resistance element. This detection part is consisted of a magnet and 2 magnetic resistance elements MR 1 and MR 2. Processing the waveform-shaping of the signal wave which is detected by the above detection part, the MP-981 obtains the rectangular wave output.

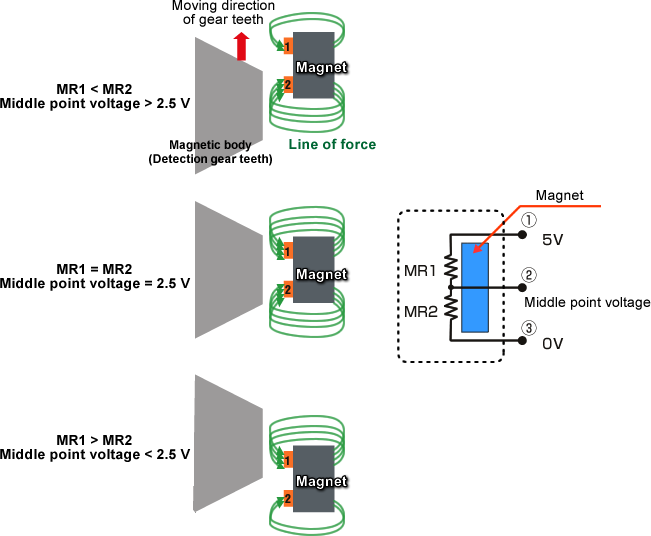

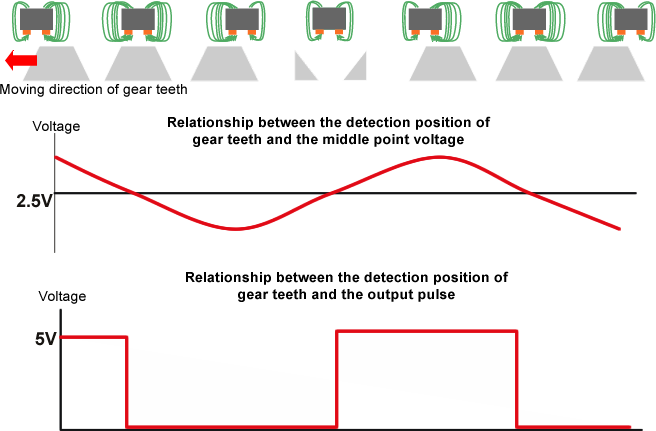

This detection part is consisted of a magnet and 2 magnetic resistance elements MR 1 and MR 2 as the following figure. The resistance value of the magnetic resistance element is relative to the additional magnetic field strength. When the magnetic body (gear) is in the front of the sensor, the magnetic field strength is changed. Therefore, when the position of the resistance body of each resistance element is unbalance, the resistance value will become unbalance. When the constant voltage is applied to the terminal 1 to 3 as following figure and measure the output voltage of terminal 2, the output signal is changed as tracing the shape of the detection gear.

Waveform-shaped signal which is obtained by the magnetic resistance sensor is set as the final signal. The signal amplitude which can be obtained by the magnetic resistance sensor is very small such as tens mV, so when the middle point voltage is changed by the temperature change or increase of the rotation speed, the change of the duty ratio or lost of the pulse output may occur.

Revised:2013.06.17