ONO SOKKI's Quality Assurance and Traceability

Quality Assurance System

In line with our policy on quality, which aims to "enhance quality as a means of endorsing the 'customer-first principle,' ",ONO SOKKI has been establishing quality control activities on a corporate-wide scale.

As a result of these activities, the Utsunomiya factory and the Technical Center at the head office, which includes the development and engineering division, were certified as conforming to the ISO 9001 Quality System in March 1996.

ONO SOKKI not only aims to maintain this certification, but will also strive to improve and enhance its quality assurance system, as is required by the ISO 9001 Quality System, in order to continually deliver better quality products to customers.

As a result of our achievements, ONO SOKKI was named Japan's first official supplier of sound level meter's in September 1997.

Furthermore, in October 1997, ONO SOKKI obtained ISO 14001 certification, the standard of environmental management systems. This demonstrates that ONO SOKKI also attaches a great deal of importance to environmental preservation.

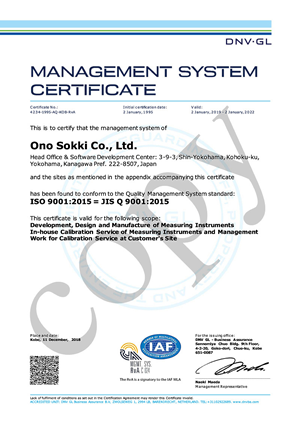

*ISO 9001 Quality System Certificate awarded to ONO SOKKI.

Control of Measuring Instruments

Quality control of measuring instruments is extremely important. It is required to ensure that their measurement results are accurate. ONO SOKKI has prepared a complete line of the reference equipment and systems needed to calibrate their measuring instruments, as well as the required measurement environment. It has established a business unit to set down the standards and procedure manuals needed for instrument calibration and to ensure calibration work is carried out smoothly.

Establishment of Reference Standards and Calibrating Equipment/Systems

In order to guarantee the accuracy of a measuring instrument, the instrument must be calibrated at regular intervals. Public institutions such as the Japan Electric Meter Inspection Corporation (JEMIC) and Japan Quality Assurance Organization (JQA), carry out calibrations on electric measuring instruments. For mechanical measuring instruments, public institutions such as the Japan Society for the Promotion of Machine Industry and other regional institutions of metrological certification, carry out the calibrations.

ONO SOKKI produces an extremely wide range of measuring instruments. In order to make calibration work more efficient, ONO SOKKI has set up its own reference standards and calibrating equipment/systems. By asking such public institutions to calibrate them (or manufacturers if the institutions will not calibrate these standards or calibrating equipment/systems) and then using the calibrated standards and calibrating equipment/systems as primary standards, ONO SOKKI carries out in-house calibration for the secondary standards and factory-use measuring instruments.

Establishment of Traceability

All measurement results of measuring instruments must be based on the same standard. It is therefore essential that these measuring instruments can be traced to the standards maintained and controlled by the nation.

In Japan, the National Institute of Advanced Industrial Science and Technology (AIST) defines the basic units of measuring standards and maintain and control these standards.

Public institutions, such as JEMIC, JQA, the Japan Society for the Promotion of Machine Industry, and regional institutions of metrological certification, are assigned these units (standards) from AIST, and use them to calibrate standards and calibrating equipment/systems submitted by the private sector.

ONO SOKKI has established its own in-house calibration system using the reference standards and calibrating equipment/systems calibrated by AIST, JEMIC and JQA.

Note: The term traceability is defined by the Japanese Industrial Standards (JIS) in the JIS Z8103 standards (glossary of measurement terms) as "the ability to show that a standard or an instrument has been calibrated by a higher-order standard which is calibrated by a still higher-order standard, and on and on, thus the standard or instrument is eventually related back to the established national standards."

ONO SOKKI's Traceability System

ONO SOKKI's traceability system is as shown in the following diagrams. All standards are calibrated at fixed intervals in compliance with the control provisions of the ISO 9001 Quality System for measuring instruments.

The system diagram is divided into part 1 and part 2.

*Note that the traceability system is shown in its simplified form.

Reference Equipment Room, Precision Instruments Room and Acoustics Lab

The accuracy of a measuring instrument is, to some degree, affected by operating environment factors such as temperature and humidity. ONO SOKKI has built a references room (for the standards of electrical measuring instruments); a precision instruments room (for the standards of mechanical measuring instruments); and an acoustics lab (for acoustic and vibrometric measurements); which are all controlled to a constant temperature and humidity. Thus, ONO SOKKI is fully equipped with work environments for precision calibration.

Control of Standards and Calibration of Measuring Instruments

ONO SOKKI's traceability system is as shown in the following diagrams. All standards are calibrated at fixed intervals in compliance with the control provisions of the ISO 9001 Quality System for measuring instruments.